Double-hanging and double-sealing type high-temperature-resistant expansion hanger

A technology of high temperature resistance and hanger, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and mining, etc., and can solve the problem of undesigned undercut mechanism, limited length of suspension tailpipe, and difficulty in effectively hanging and other problems, to achieve the effect of facilitating undercut operation, improving suspension and sealing performance, and increasing the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

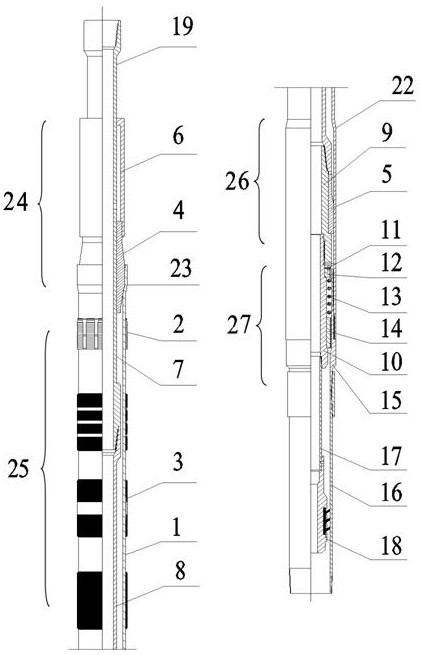

[0037]Reference attachedfigure 1 , A dual-suspension dual-sealed high-temperature resistant expansion hanger, comprising an expansion suspension cylinder 1, a slip seating mechanism 24, a suspension sealing mechanism 25, an expansion mechanism 26 and an inverted mechanism 27. among them:

[0038]The expansion suspension cylinder 1 is an expandable short section, and its top and bottom are respectively processed with a pre-expanded, upper bell-shaped expansion outlet 23 and a lower bell-shaped expansion starter 22; the bottom of the expansion suspension cylinder 1 is changed The buckle joint 15 is fixedly connected to the tail pipe 16.

[0039]The slip setting mechanism 24 includes a central tube 7, an upper expansion cone 4, and a hydraulic mechanism 6. The hydraulic cylinder mechanism 6 is connected to the upper expansion cone 4, and the upper expansion cone 4 is provided with a downward expansion cone and is preset At the expansion outlet 23 of the expansion suspension cylinder 1, the u...

Embodiment 2

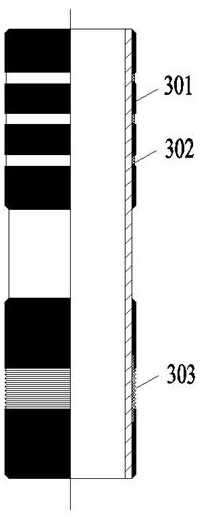

[0045]Reference attachedimage 3 , On the basis of Example 1, further includes:

[0046]The sealing cylinder 3 is composed of one or more combinations of rubber cylinder 301, rubber cylinder 301-trapezoidal metal ring 302, or rubber cylinder 301-sawtooth metal ring 303. The rubber cylinder 301 is made of high-temperature resistant fluororubber, and the outer surface of the expansion suspension cylinder 1 at the rubber cylinder 301 is provided with metal protrusions that are in position-limiting coordination with the rubber cylinder 301. The trapezoidal metal ring 302 has a wide outside and a narrow structure. The trapezoidal metal ring 302 and the zigzag metal ring 303 are made of soft metal materials, and the outer diameter is slightly smaller than the outer diameter of the rubber cylinder 301.

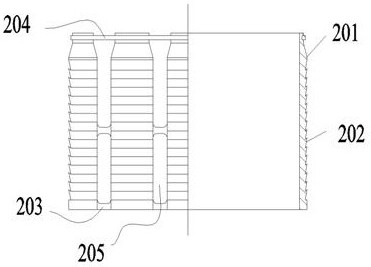

[0047]Reference attachedfigure 2 Slip teeth 202 are processed on the slip block 201, and the adjacent slip blocks 201 are fixed by connecting ribs 203 and a fixing ring 204; the connecting rib 20...

Embodiment 3

[0050]Reference attachedFigure 1 to 3, A dual-suspension dual-sealed high-temperature resistant expansion hanger, including expansion suspension cylinder 1, slips sitting mechanism 24, suspension sealing mechanism 25, expansion mechanism 26, inverted buckle mechanism 27, buckle joint 15 and tail pipe 16 components .

[0051]The expansion suspension cylinder 1 is an expandable casing short section, the top and bottom of which are respectively processed with a pre-expanded, upper bell-shaped expansion outlet 23, a lower bell-shaped expansion starter 22, and a slip hanging mechanism 24 The upper expansion cone 4 is preset in the expansion outlet 23. The tail pipe 16 is threadedly connected with the expansion starter 22 at the bottom of the expansion suspension cylinder 1 through a buckle joint 15.

[0052]The suspension sealing mechanism 25 mainly includes a metal slip 2 and a multi-segment sealing cylinder 3. Both the metal slip 2 and the sealing cylinder 3 are fixed on the outer surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com