Self-sensing compression type high-sealing-performance straight-through gate valve

A compressive, high-sealing technology, applied in shaft seals, engine seals, sliding valves, etc., can solve problems such as difficult maintenance, reduced sealing reliability, and medium leakage, so as to improve the sealing effect, reduce rotational resistance, and realize The effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

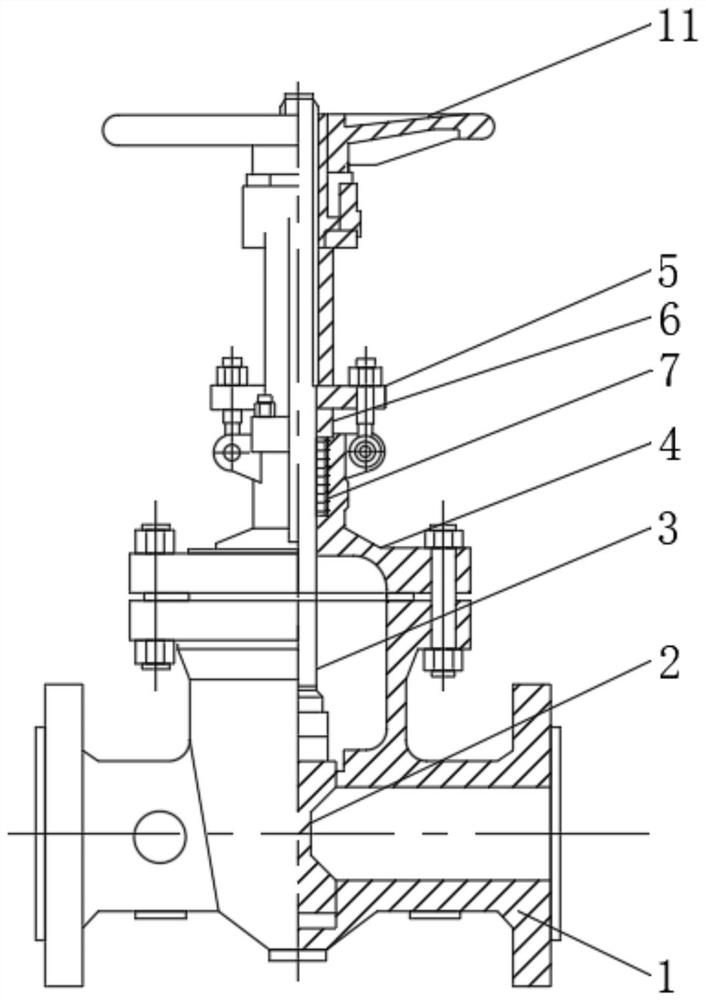

[0043] see figure 1 , a self-sensing compression type high-tightness straight-through gate valve, including a valve body 1, a valve cover 4 is installed on the upper end of the valve body 1, a valve plate 2 is installed inside the valve body 1, a valve stem 3 is installed on the upper end of the valve plate 2, and the valve cover 4. The upper end of the packing plate 5 is installed with a packing gland 6. The lower end of the packing gland 6 is equipped with an elastic packing 7. The upper end of the packing plate 5 is equipped with a hand wheel 11, and the hand wheel 11 is connected with the valve stem 3.

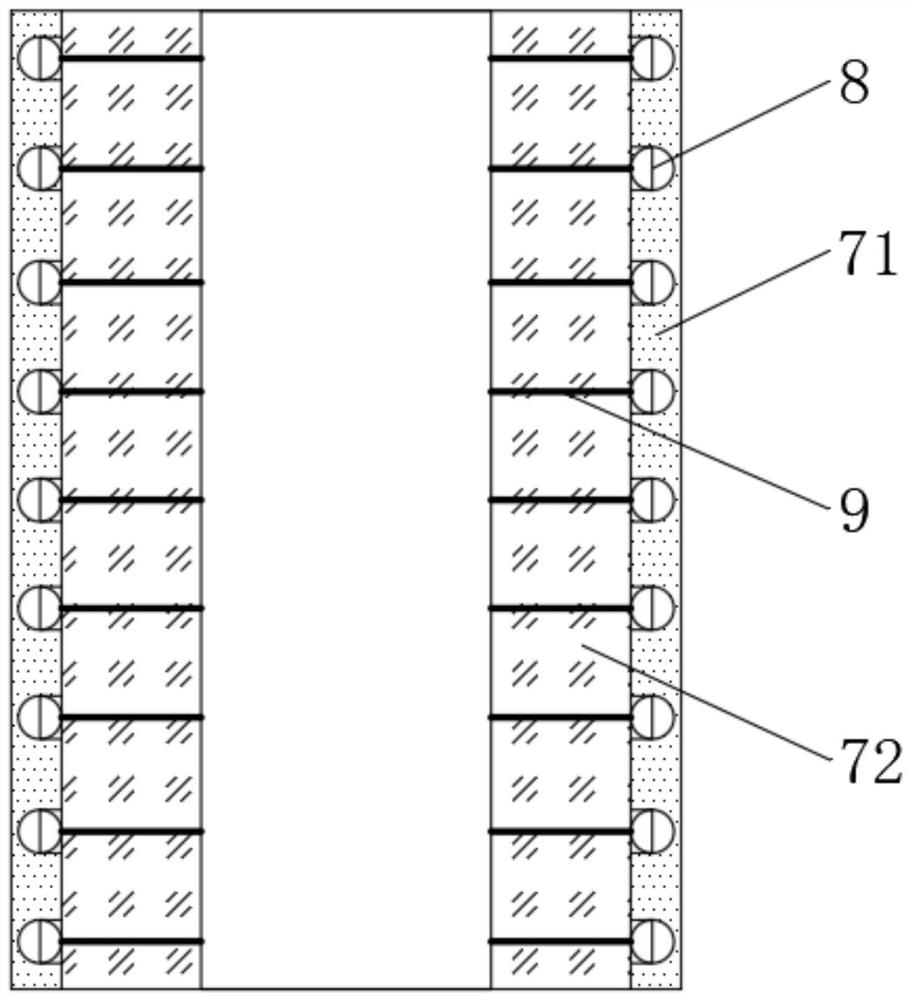

[0044] see figure 2 , the elastic packing 7 includes a protective outer layer 71 and a compressed inner layer 72, and the compressed inner layer 72 is connected to the inner end of the protective outer layer 71, and the inner end of the protective outer layer 71 is provided with a plurality of evenly distributed migration grooves, and the migration grooves are provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com