Compound rubber sealing ring of ultra-large water supply spigot and socket pipe

A kind of rubber sealing ring, composite technology, which is applied in the direction of engine sealing, sleeve/socket connection, pipe/pipe joint/pipe fitting, etc., can solve the problem of high construction cost, general sealing effect of rubber sealing ring, and construction time of pipe network laying. Long and other problems, to achieve the effect of reducing construction cost, good connection effect, convenient and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

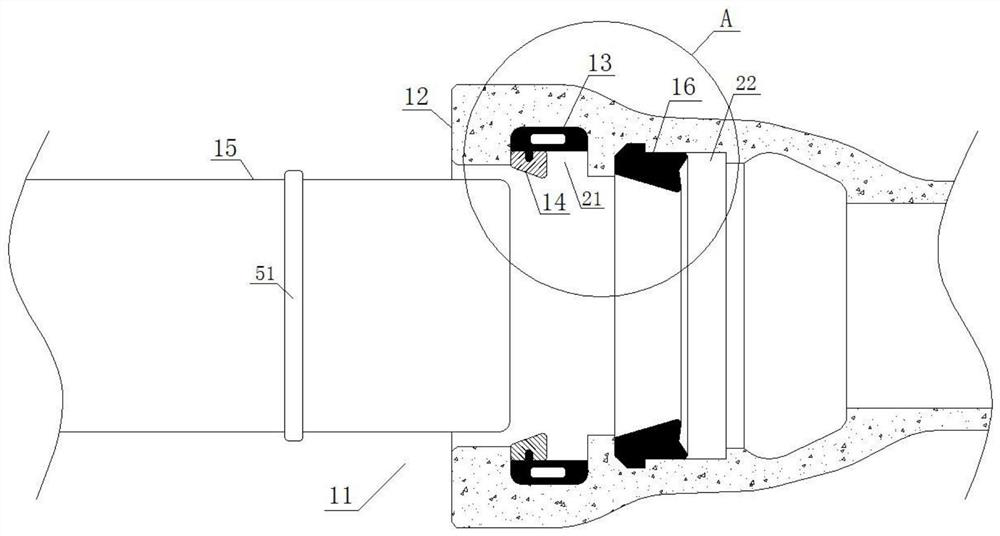

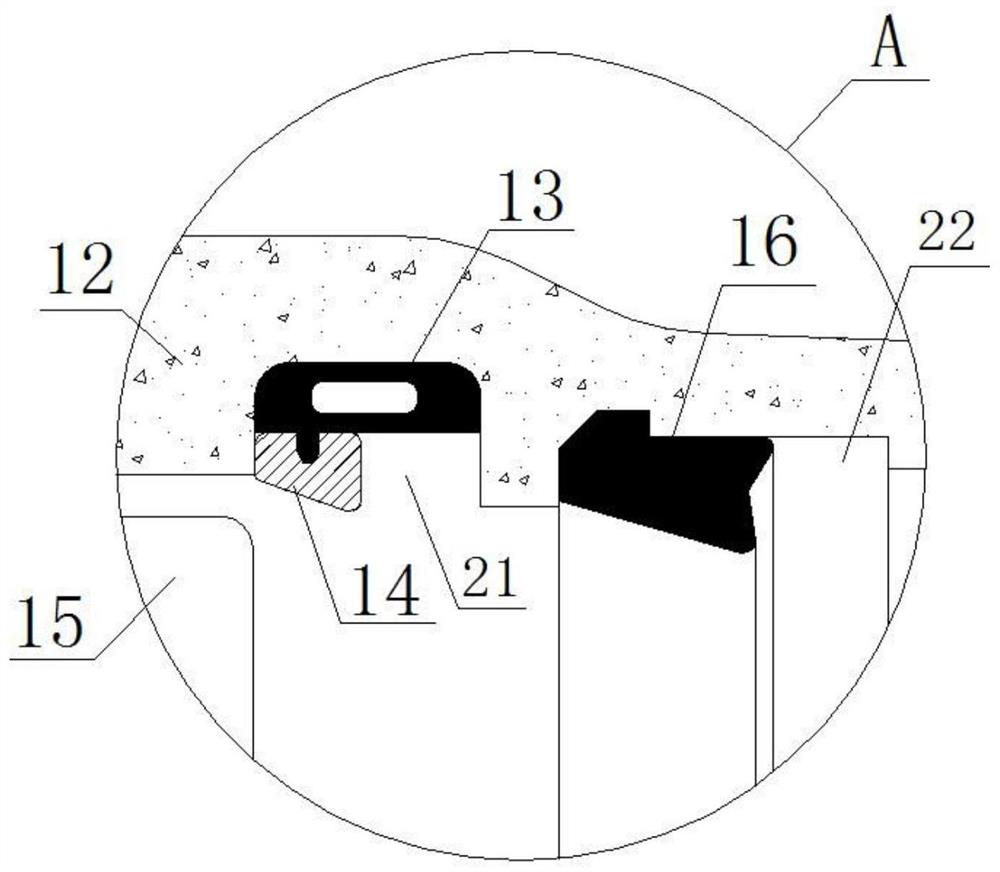

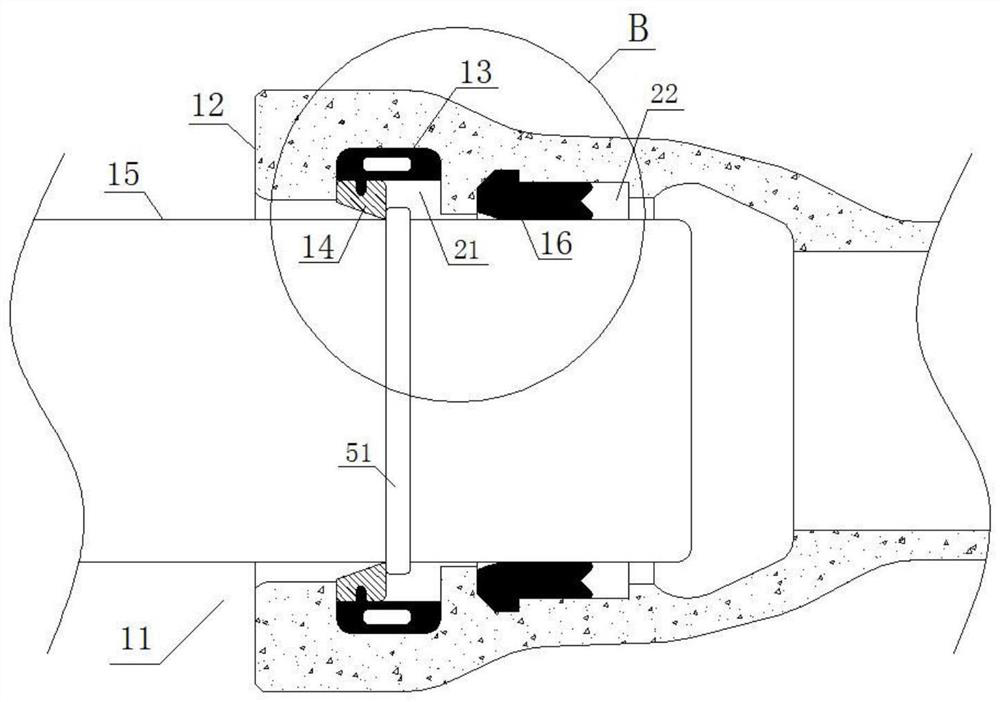

[0032] The application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain related inventions, rather than to limit the invention. It should also be noted that, for ease of description, only parts related to the invention are shown in the accompanying drawings.

[0033] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The application will be described in detail below with reference to the accompanying drawings and embodiments.

[0034] Please refer to Figure 1 to Figure 10 , the embodiment of the present application provides a composite rubber sealing ring for a super-large water supply socket pipe, including an anti-slip ring groove 21 disposed in the socket 12 of the socket pipe 11 near the end; the anti-slip ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com