Metal surface treatment spraying device with continuous spraying and horizontal movement structure and operation method thereof

A technology for metal surface treatment and spraying device, which is applied to the device for coating liquid on the surface, the spraying device, the pretreatment surface, etc., which can solve the problems of the dead angle of the sprayed object, the poor working quality of the spraying device, and the difficulty of spraying the spraying device. , to achieve the effect of improving work efficiency and reducing dead ends of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

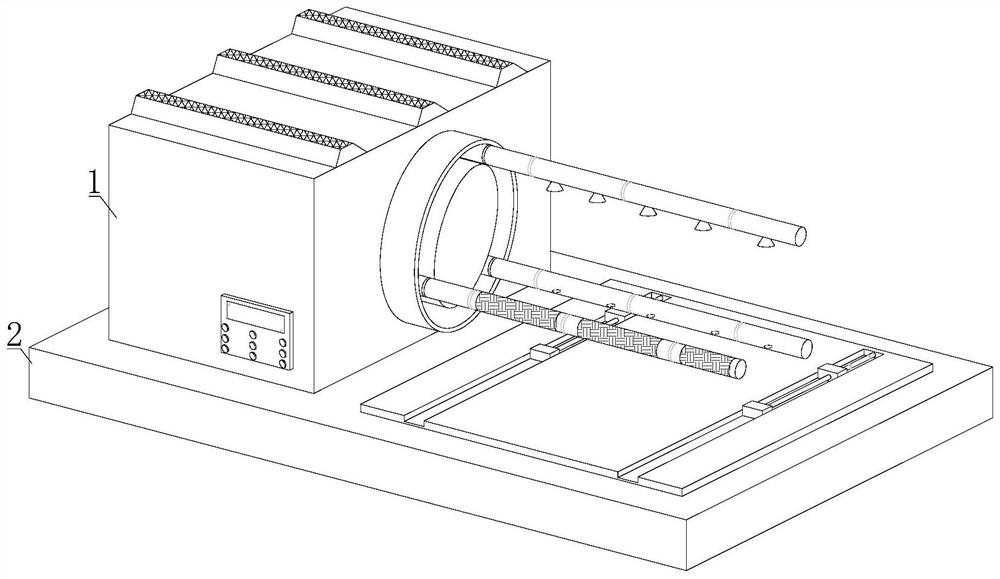

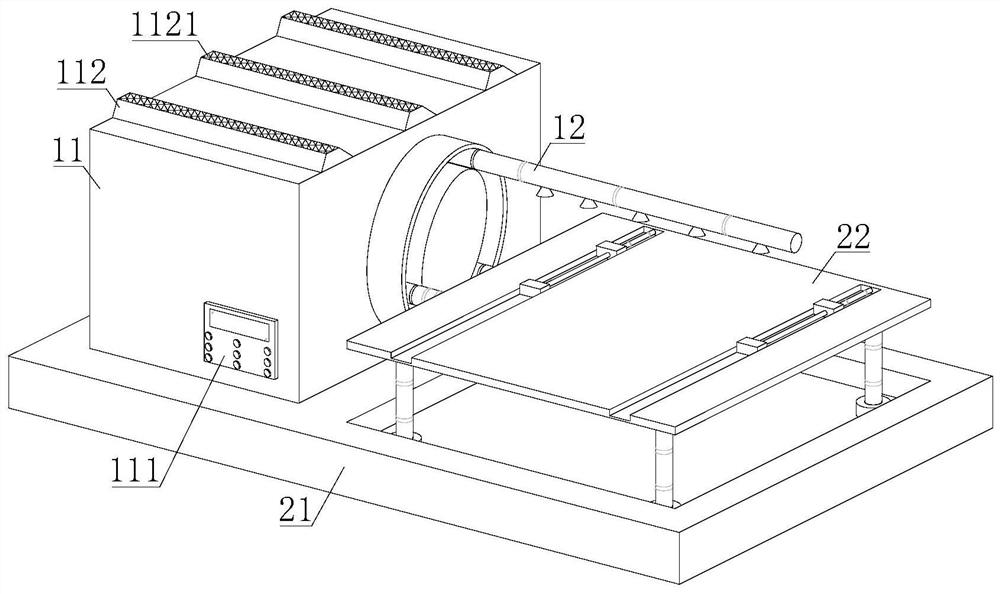

[0030] refer to figure 1 , 2 And 7, a metal surface treatment spraying device with a continuous spraying translation structure, including an operating mechanism 1 and a supporting mechanism 2, the upper end of the supporting mechanism 2 is provided with an operating mechanism 1, and the operating mechanism 1 includes a box body 11 and a spraying mechanism 12, One side of the box body 11 is provided with a spraying mechanism 12, the spraying mechanism 12 is connected with the support mechanism 2 through the box body 11, the box body 11 includes a control panel 111, an end block 112, an air pump A113, a motor 114, an air pump B115 and a connecting pipe 116 , a control panel 111 is fixedly installed on the outer surface of the box body 11, an end block 112 is fixedly installed on the upper surface of the box body 11, a heat dissipation grid 1121 is arranged on the upper surface of the end block 112, and the air pump A113, the motor 114 and the air pump B115 are all set Inside th...

Embodiment 2

[0032] refer to Figure 5 and 6, the spraying mechanism 12 comprises fixed disk 121, spraying pipe 122, grinding pipe 123, air blowing pipe 124 and fixture 125, one side of fixed disk 121 is provided with spraying pipe 122, grinding pipe 123 and blowing pipe 124, spraying pipe 122, grinding One end of pipe 123 and air blowing pipe 124 is all provided with fixture 125, and one side of fixed disc 121 is provided with arc groove 1211, and spraying pipe 122, polishing pipe 123 and air blowing pipe 124 are all connected with arc groove 1211 by fixture 125. Connection, the outer surface of the spray pipe 122 is provided with a continuous nozzle 1221, one end of the continuous nozzle 1221 is provided with a threaded joint 1222, the continuous nozzle 1221 is movably connected with the spray pipe 122 through the threaded joint 1222, and the outer surface of the grinding pipe 123 is provided with a frosting layer 1231, the outer surface of the air blowing pipe 124 is provided with an a...

Embodiment 3

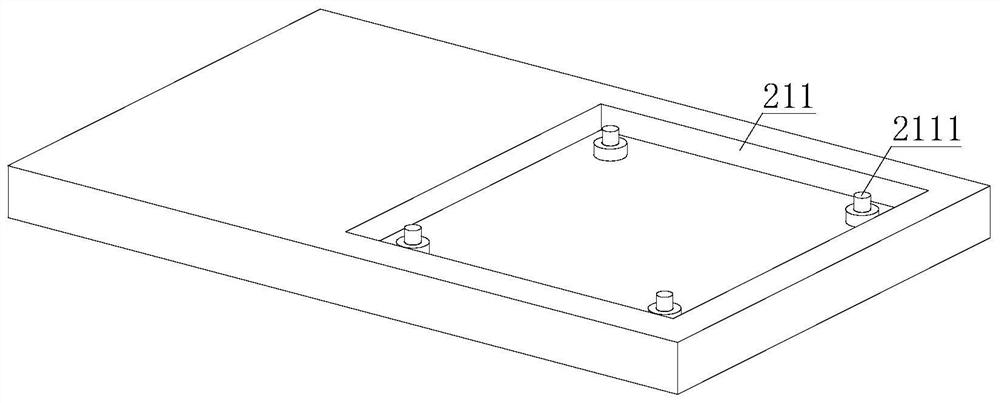

[0034] refer to image 3 , 4 And 7, the output end of motor 114 is provided with curved rod 1141 and straight rod 1142, and motor 114 is connected with fixture 125 by curved rod 1141, and motor 114 is connected with grinding tube 123 by straight rod 1142, and motor 114 is connected with external power supply. The motor 114 is connected with the control panel 111 signal, one end of the air pump B115 is provided with an air pipe 1151, the other end of the air pump B115 communicates with the outside world, the air pump B115 communicates with the blowing pipe 124 through the air pipe 1151, and one end of the communication pipe 116 It is connected with the spraying pipe 122, the other end of the connecting pipe 116 is connected with the external paint, the air pump A113 is connected with the outer surface of the connecting pipe 116, the air pump A113 and the air pump B115 are connected with the control panel 111 for signals, and the upper surface of the bottom plate 21 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com