Automobile stamping sheet edge cutting device and using method thereof

A technology for stamping and trimming, which is applied in the field of trimming devices for automotive stamping sheets, can solve the problems of reducing trimming efficiency, unable to collect scraps, unable to automatically take out stamped sheets, etc., and achieve good trimming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

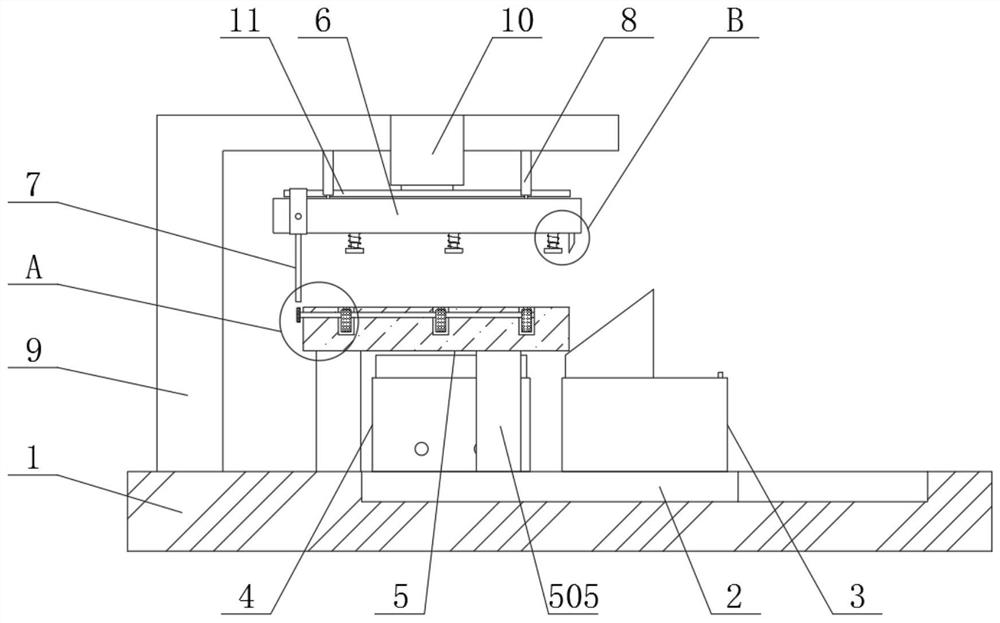

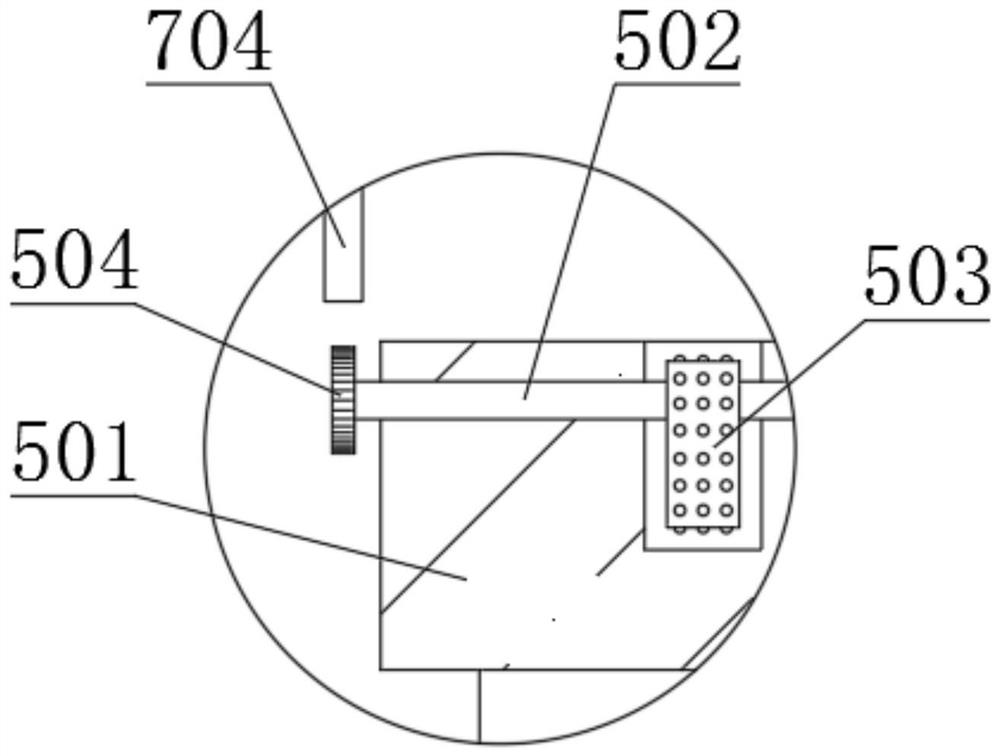

[0037] see Figure 1-2 -3-4-5-6-9, the present invention provides a technical solution:

[0038] An automobile stamping thin plate edge trimming device and its use method, including placing a bottom plate 1 and a bracket 9, a conversion slide plate 2 is slidably connected to the inside of the top end of the base plate 1, and a corner collecting device 3 and a burr collection device are fixedly connected to the top of the conversion slide plate 2 Device 4, this arrangement can respectively collect the larger leftover material or burr debris after trimming through the corner collecting device 3 and the burr collecting device 4, the corner collecting device 3 is arranged on the right side of the burr collecting device 4, and the edge The angle collection device 3 comprises a corner collection box 301, a first guide bucket 302, an electric roller 303, a corner collection box 304, a first eccentric wheel 311, and the burr collection device 4 comprises a burr concentration box 401, ...

Embodiment 2

[0042] see Figure 1-2 -3-7-8-9, the present invention provides a technical solution:

[0043] An automobile stamping sheet trimming device and its use method, the same parts in embodiment 2 as in embodiment 1 will not be repeated in the present invention, and the difference lies in the working process.

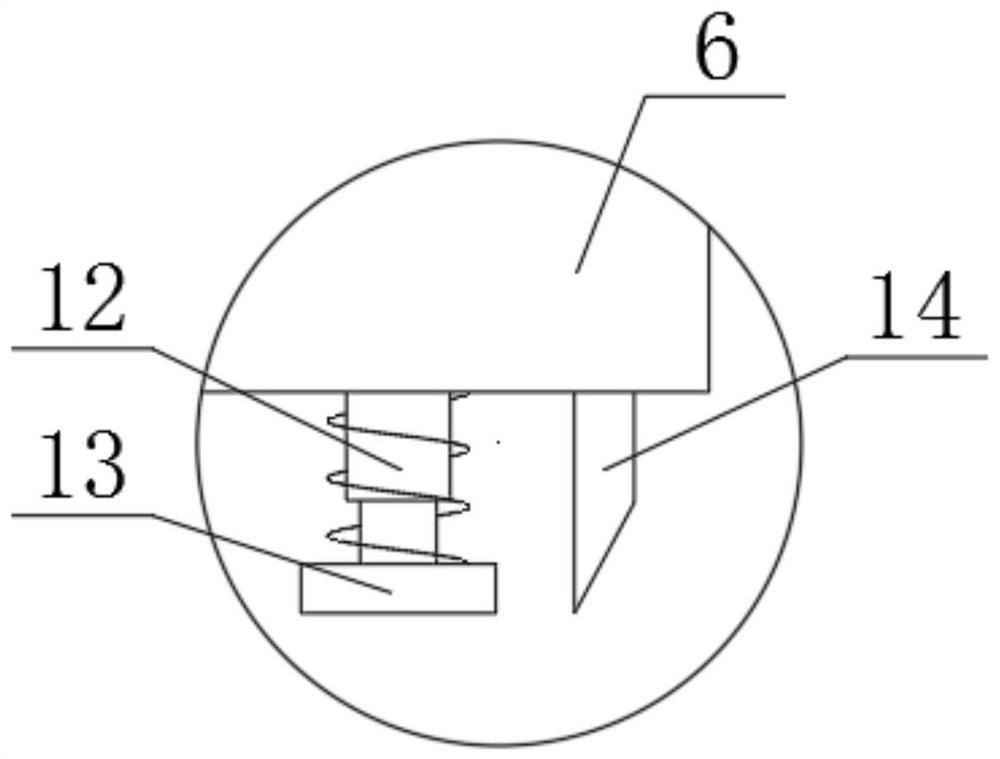

[0044]Work flow: the present invention supplies power through an external power supply before use, places the stamped thin plate that needs to be trimmed on the top of the placement plate 501, and then starts the hydraulic push rod 10 to make the hydraulic push rod 10 push the push plate 11 to make the The stamping plate 6 moves downward, and the pneumatic buffer spring 8 ensures that the stamping plate 6 drives the trimming knife 14 to trim the stamped sheet at a constant speed, and the stamped sheet is clamped by the elastic telescopic rod 12 and the clamping block 13 to avoid punching the sheet When the hydraulic push rod 10 pushes the stamping plate 6 downward through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com