On-rail tooling system for truss assembly with variable scale and complex configuration

A variable-scale and complex technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of slow lap joint efficiency, complicated control, low safety, etc., and achieve less driving, large folding ratio, and structural compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

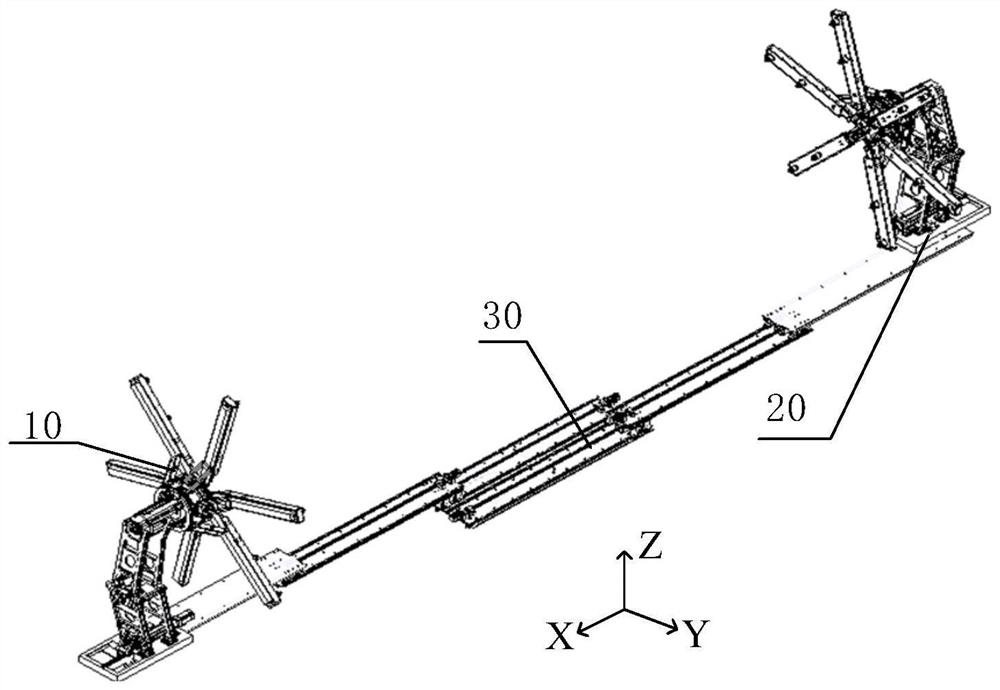

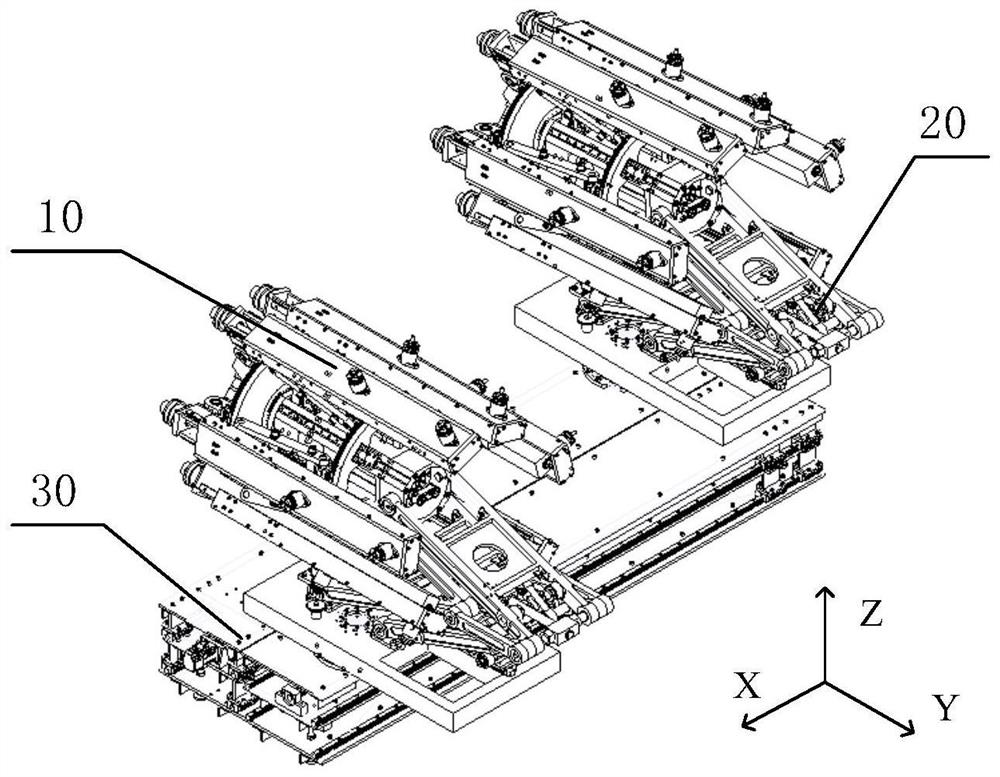

[0052] The on-rail tooling system for truss assembly with variable scale and complex configuration provided by the present invention, such as figure 1 and figure 2 As shown, it includes an installation planar mechanism 10, a folding support mechanism 20 and a drawer bottom plate mechanism 30. The two folding support mechanisms 20 are respectively installed at opposite ends of the same side of the drawer bottom plate mechanism 30. The two installation plane mechanisms 10 are respectively It is relatively installed on the inner side of the upper part of the two folding support mechanisms 20 .

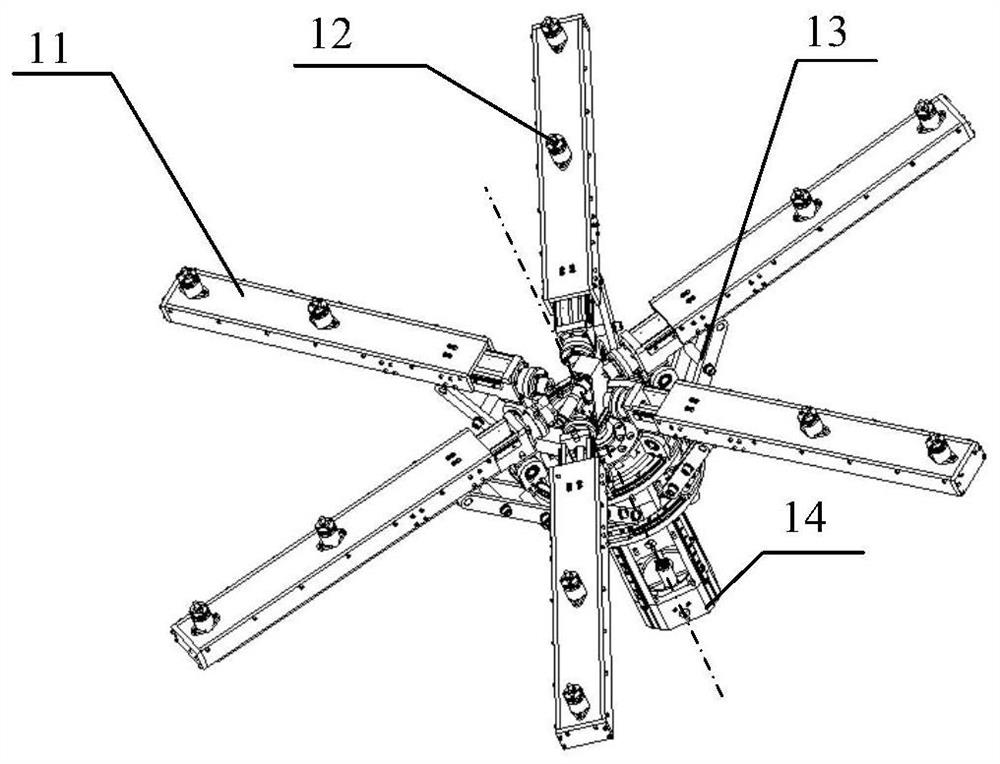

[0053] Such as image 3 As shown, the installation plane mechanism 10 includes a head frame 14, a movable support arm 11, a push-up support arm 13 and a head fixing lock 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com