A multifunctional workbench for electronic product processing

A technology for electronic products and workbenches, applied in workbenches, manufacturing tools, etc., can solve the problems of inability to protect products against dust, and inability to collect nuts and nuts, saving manpower and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

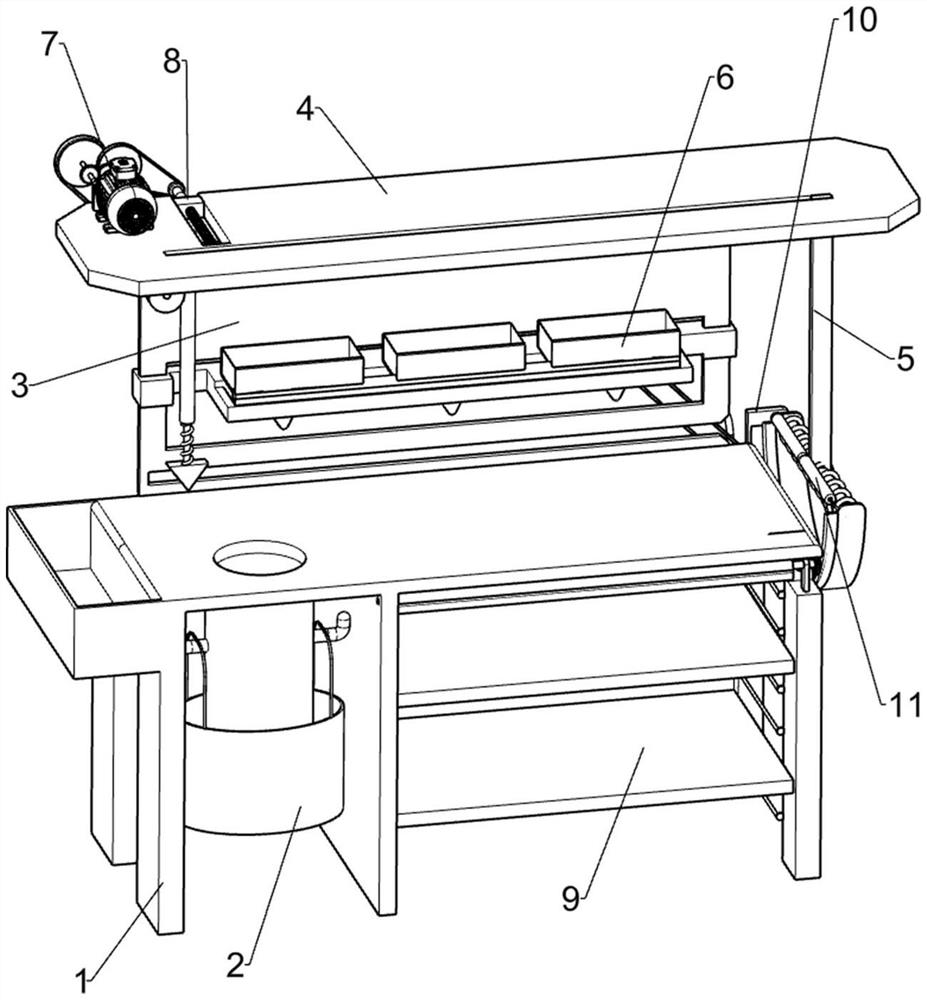

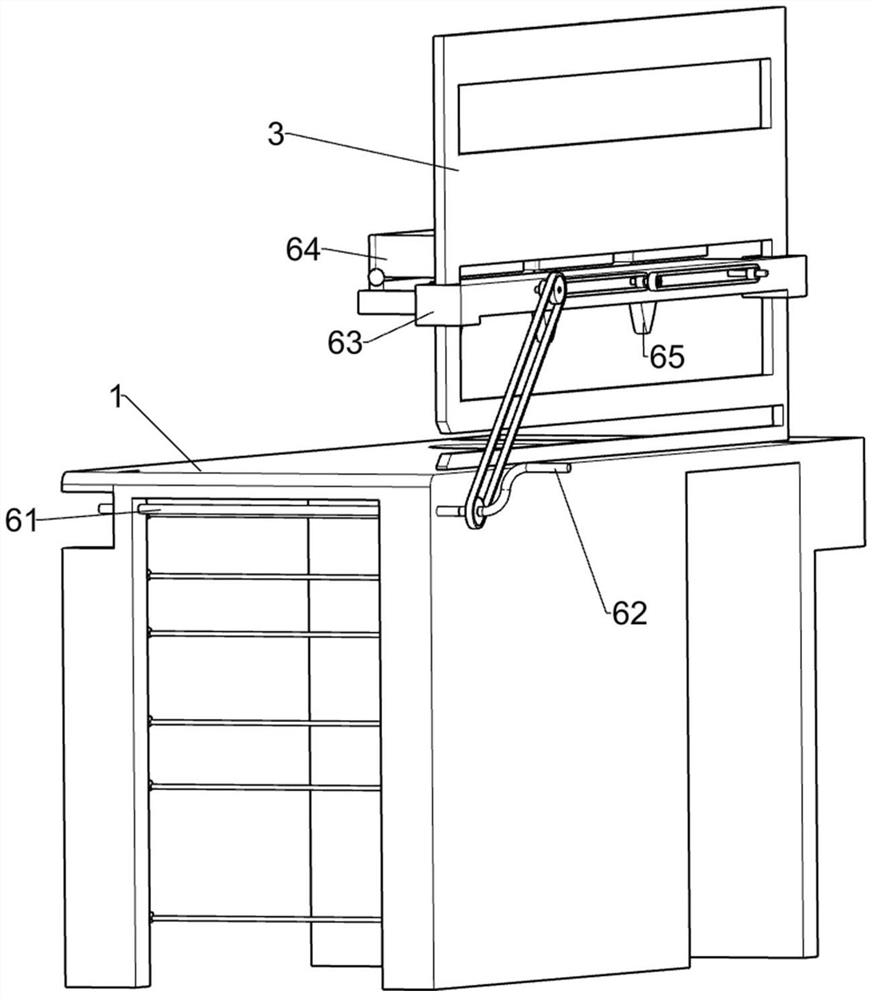

[0030] A multifunctional workbench for electronic product processing, such as Figure 1-3 As shown, it includes a workbench 1, a cleaning bag 2, a side plate 3, a top plate 4, a cleaning assembly 5 and a storage assembly 6, a round hole is provided on the left side of the top of the workbench 1, and a square groove is provided at the left end of the workbench 1. A cleaning bag 2 is provided at the bottom of the hole, a side plate 3 is connected to the top and back of the workbench 1, a top plate 4 is connected to the top of the side plate 3, a cleaning component 5 is slidingly connected to the front side of the top plate 4, and a storage unit is connected to the lower part of the side plate 3 6.

[0031] The cleaning assembly 5 includes a slide bar 51, a rotating bar 52, a first arc scraper 53, a torsion spring 54, a second arc scraper 55 and a long spring 56, and the front side of the top plate 4 is slidably connected with a slide bar 51. The bottom of the rod 51 is rotatabl...

Embodiment 2

[0035] On the basis of Example 1, such as Figure 4 As shown, drive assembly 7 is also included, and drive assembly 7 includes second rotating shaft 71, pulley 72, stay wire 73, third rotating shaft 74, first gear 75, motor 76 and missing gear 77, top plate 4 bottom front side rotary type A second rotating shaft 71 is connected, and the front end of the second rotating shaft 71 is connected with a pulley 72. A backguy 73 is connected between the pulley 72 and the slide bar 51. The rear side of the top plate 4 is rotationally connected with a third rotating shaft 74. Two rotating shafts 71 transmission connections, the third rotating shaft 74 middle part is connected with first gear 75, top plate 4 top left side is equipped with motor 76, and motor 76 output shafts are connected with missing gear 77, and missing gear 77 is meshed with first gear 75.

[0036] When the workbench 1 needs to be cleaned after the processing is completed, the staff starts the motor 76 and rotates to ...

Embodiment 3

[0038] On the basis of Example 2, such as Figure 4 As shown, front and rear assemblies 8 are also included. Front and rear assemblies 8 include screw mandrels 81, poles 82, wedge blocks 83, return springs 84 and second gears 85. The rear side of the screw mandrel 81 is threadedly connected with a support rod 82, the bottom of the support rod 82 is slidably connected with a wedge block 83, and a return spring 84 is sleeved between the wedge block 83 and the support rod 82, and the front side of the top plate 4 is rotationally connected with a The second gear 85 , the second gear 85 meshes with the missing gear 77 , and the second gear 85 is in transmission connection with the screw mandrel 81 .

[0039] When slide bar 51 moves to the left and drives rotating rod 52 to move to the left and contact with wedge-shaped block 83, rotating rod 52 moves to the left and drives wedge-shaped block 83 to move upwards, and wedge-shaped block 83 moves upwards and return spring 84 is compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com