Concrete manufacturing and smearing all-in-one machine

An all-in-one machine and concrete technology, which is applied in the fields of clay preparation device, raw material supply device for sale, building structure, etc., can solve the problems of time-consuming, labor-intensive, bulky, and increase operating costs, and achieve cost reduction, equipment volume control, and time saving. The effect of saving labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

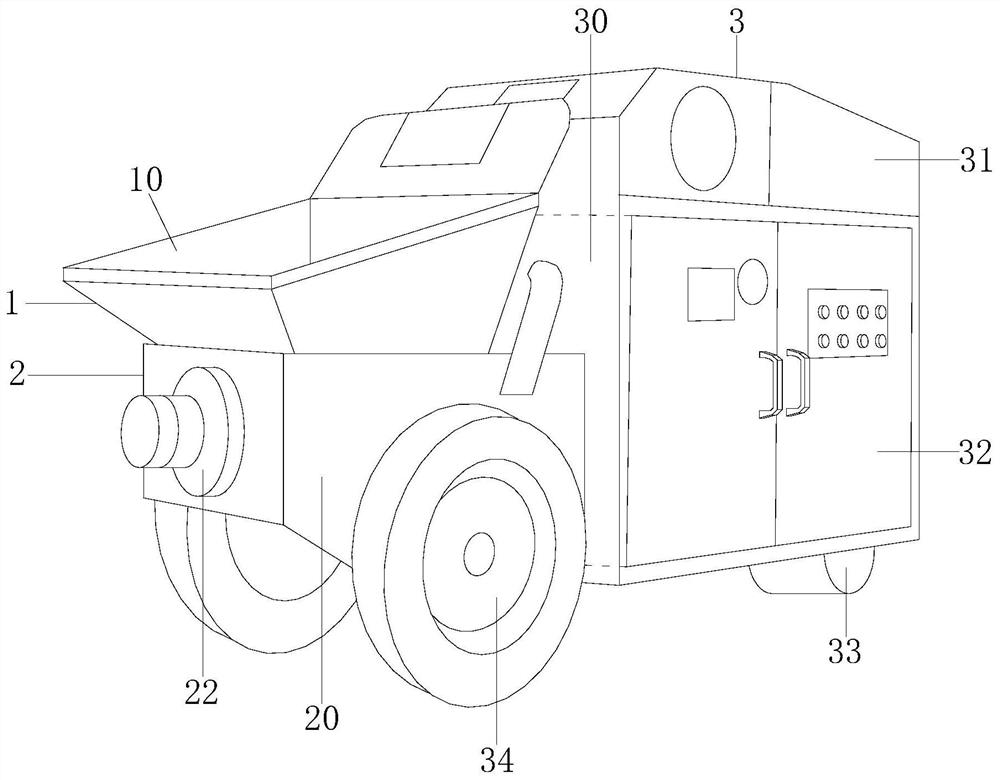

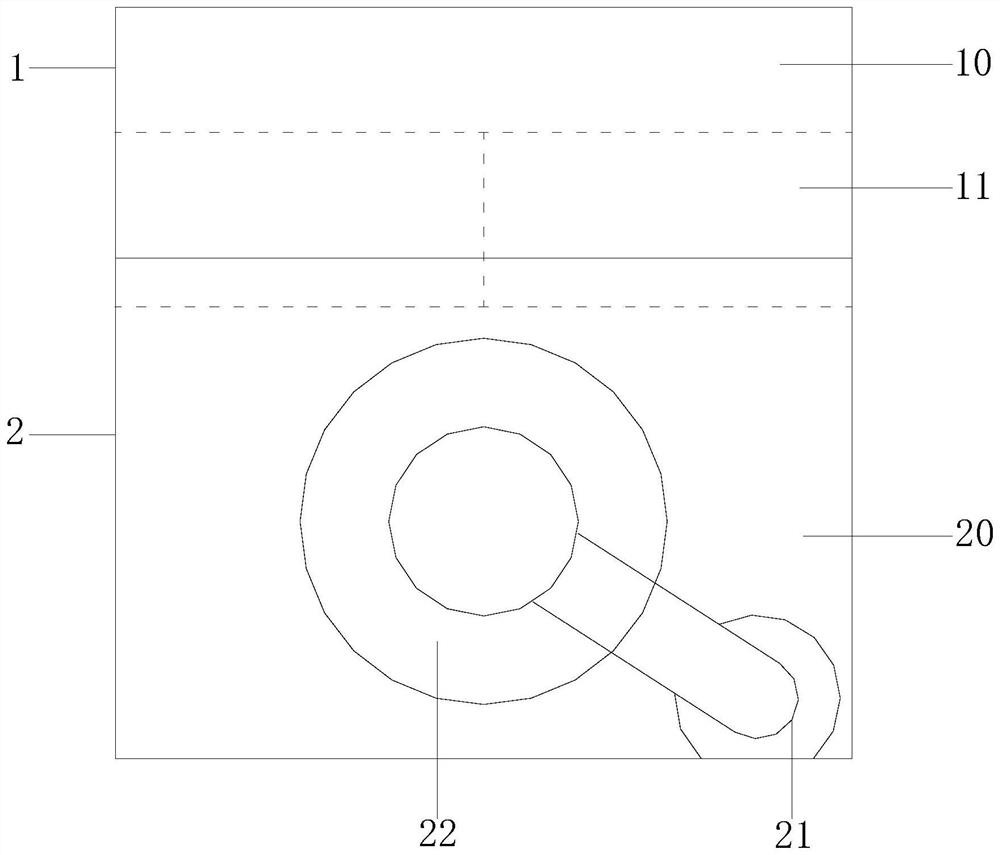

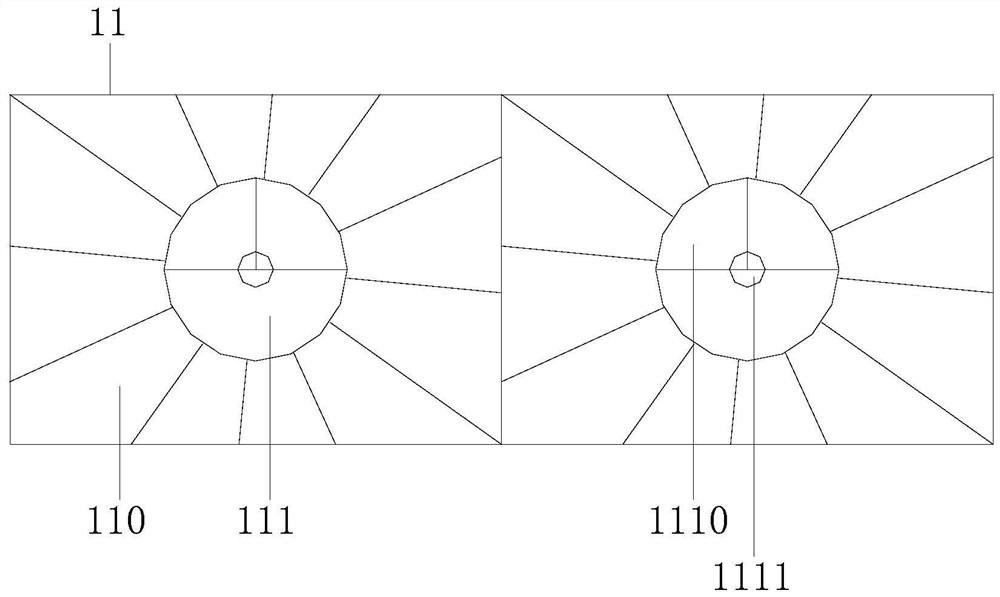

[0025] Example 1 see Figure 1-3 , the present invention provides a technical solution for a concrete making and painting all-in-one machine: its structure includes a feed hopper 1, a painting box structure 2, and a main transmission control box 3. Installed and connected, the feed hopper 1 is located above the smear box structure 2, the feed hopper 1 is composed of a hopper body 10 and a feed port 11, the hopper body 10 is equipped with a feed port 11, and the smear box Structure 2 includes a smear box frame 20, a feeder 21, and a smear device 22, the smear box frame 20 is connected to the smear device 22, the feeder 21 is installed on the smear device 22, and the feed port 11 includes Concave frame 110, screw feed port 111, the feed port 11 is a concave structure, the material slides along the concave frame 110 to the screw feed port 111, and then enters the internal stirring device 30 in a spiral manner, and the materials are classified into Once entering, the feed is orde...

Embodiment 2

[0027] Example 2 see Figure 4-6 , the present invention provides a technical solution for a concrete making and painting all-in-one machine: the internal mixing device 30 includes an upper assembly frame 300, a lower assembly frame 301, an assembly round button 302, and a stirring device 303. The upper assembly frame 300 and the lower assembly The assembly frame 301 is assembled and connected, the upper assembly frame 300, the lower assembly frame 301 are installed and connected with the assembly round button 302, the stirring device 303 is installed on the upper assembly frame 300, the lower assembly frame 301, and the stirring device 303 includes a stirring Inner cylinder 3030, stirring shaft fan 3031, automatic material opening 3032, the stirring inner cylinder 3030 is installed and connected with the stirring shaft fan 3031, the stirring shaft fan 3031 is used for stirring materials, and is obliquely installed on the stirring inner cylinder 3030, Stirring inner cylinder 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com