Plastic processing granulator

A granulator and plastic technology, applied in the field of plastic processing machines, can solve problems such as water vapor cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

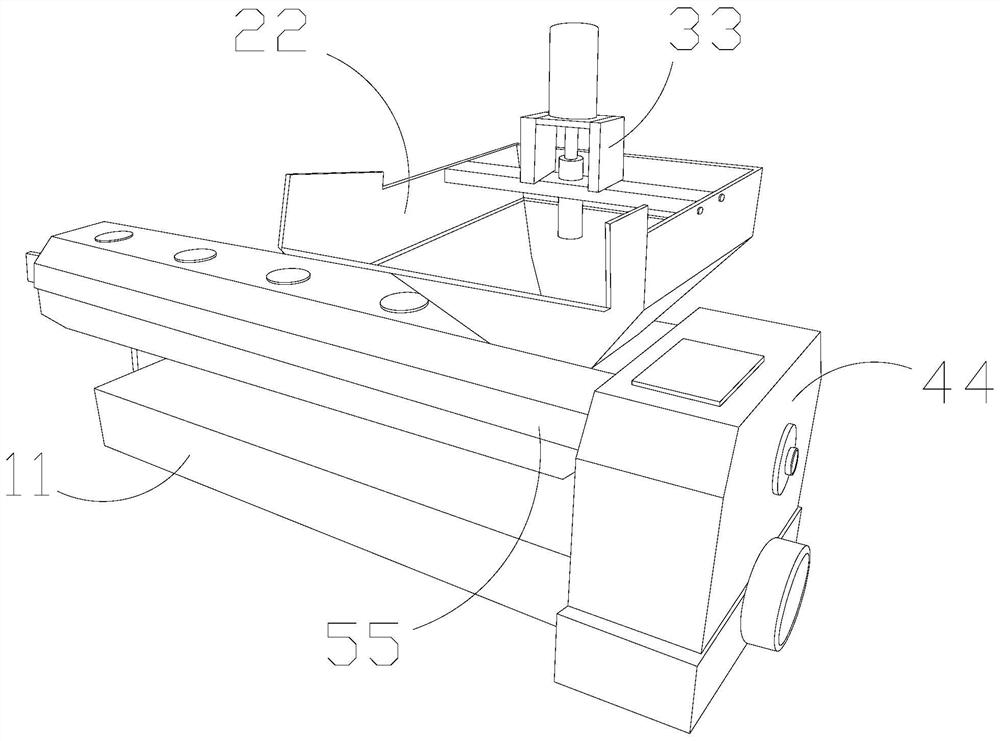

[0032] as attached figure 1 to attach Figure 6 Shown:

[0033] The present invention provides a plastic processing and granulating machine, the structure of which comprises a bottom box 11, a hopper 22, a stirring head 33, a pressure box 44, and a molding box 55. The bottom box 11 is installed below the molding box 55 and is parallel to each other. The stirring head 33 is welded on the inner surface of the hopper 22 , the hopper 22 is fixed on the upper surface of the forming box 55 and penetrates each other, and the forming box 55 and the pressure box 44 are welded and penetrated each other.

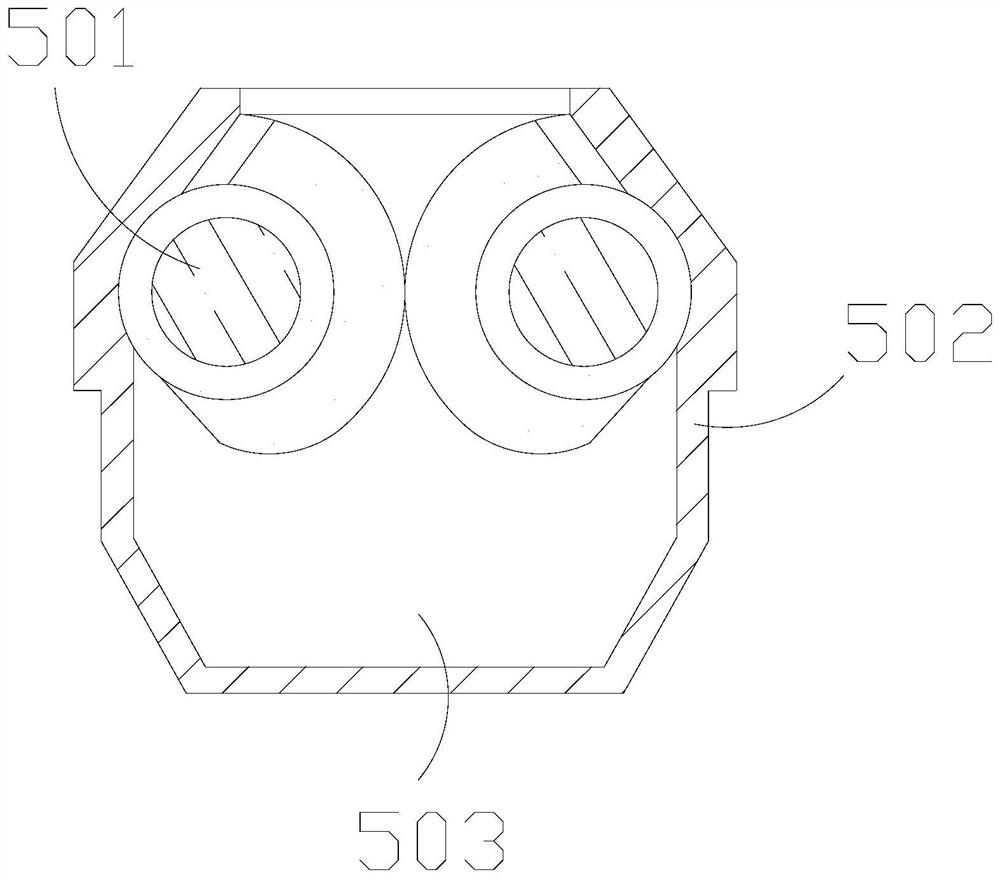

[0034] The forming box 55 includes a pressing body 501 , an outer frame 502 and an inner tank 503 , the pressing body 501 is movably connected with the outer frame 502 , and the inner tank 503 is installed inside the outer frame 502 .

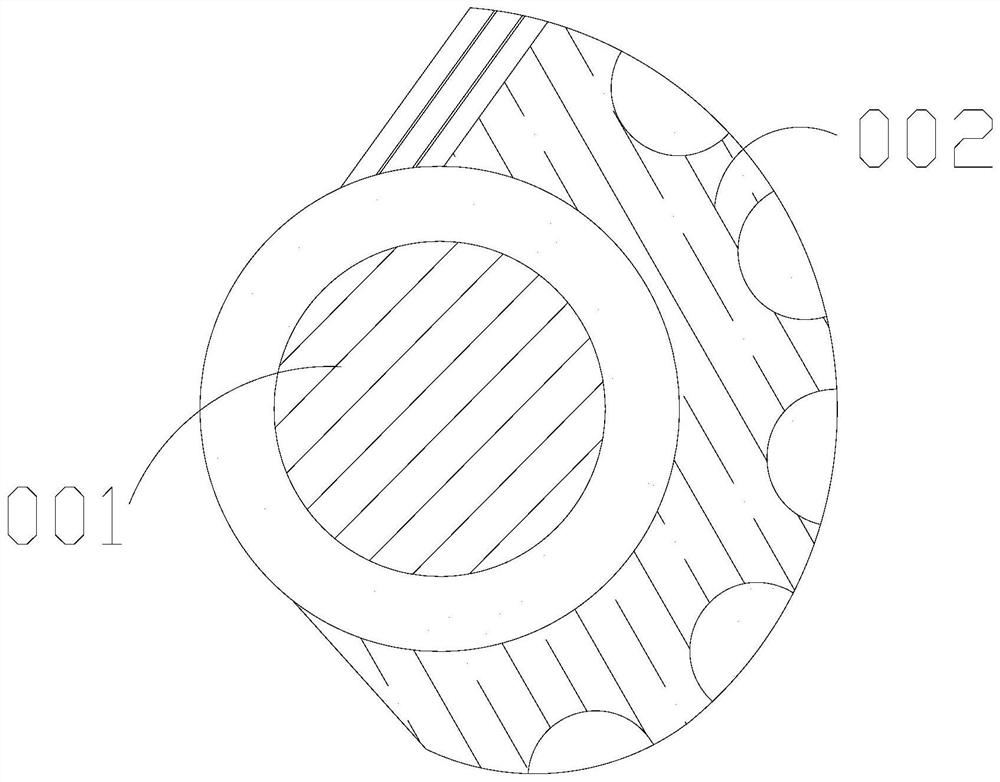

[0035] Wherein, the pressure body 501 includes a central shaft 001 and a curved body 002, the curved body 002 is fixed on the outer surface of the ce...

Embodiment 2

[0042] as attached Figure 7 to attach Figure 9 Shown:

[0043] Wherein, the central axis 001 includes an extension ring 511, an inner rubber ring 512, an extension body 513, and a pituitary body 514. The extension ring 511 is wrapped on the outer surface of the inner rubber ring 512, and the extension body 513 is connected with the extension ring 511. The pituitary 514 runs through the inside of the extension ring 511. The inner rubber ring 512 is made of rubber material and has a certain toughness. The extension ring 511 fixes the position of the overall outer frame. swing within the range.

[0044] Wherein, the pituitary gland 514 includes a main ball g11, a solid block g12, and a rubber strip g13, the rubber strip g13 is fixed between the main ball g11 and the solid block g12, the main ball g11 is a spherical structure, and the rubber strip g13 It is made of rubber material and has a certain toughness. The main ball g11 fixes the force point of the connection part, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com