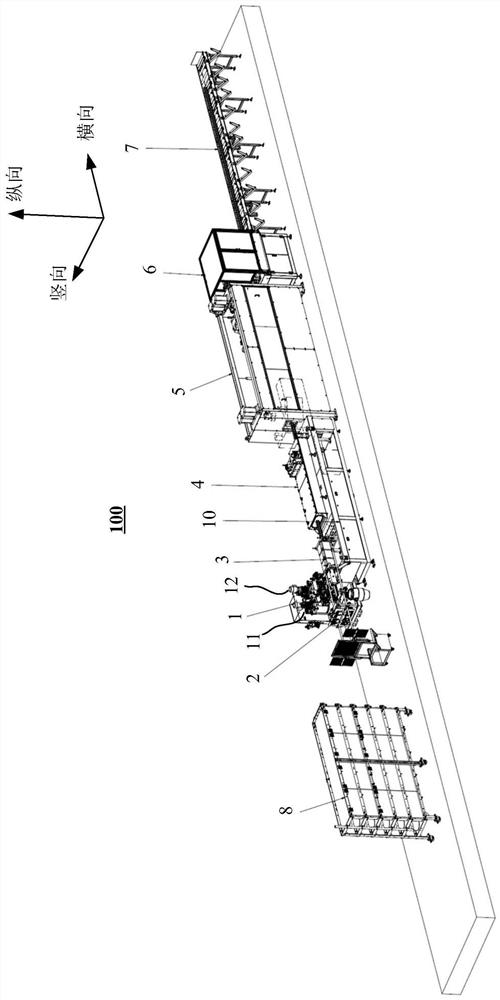

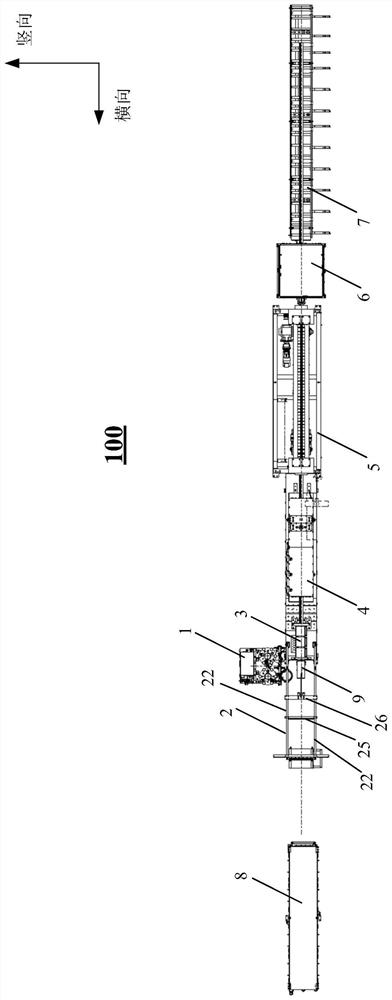

Pultrusion process system

A technology of pultrusion and crawler, which is applied in the direction of coating, etc., can solve the problems of unreliable fixation of mandrel and yarn guide structure, unfavorable rapid adjustment and replacement, and lengthening of production line length, so as to save time for disassembling and assembling track shoes, fix them Reliable and improved cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

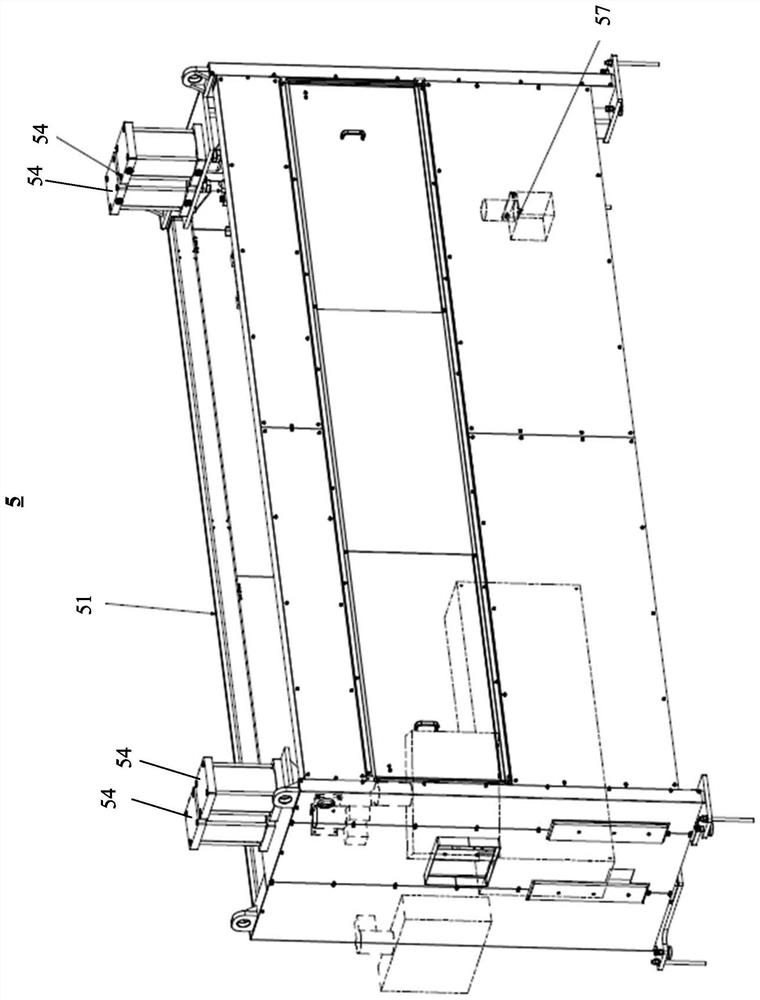

Method used

Image

Examples

Embodiment Construction

[0038] A variety of different implementations or examples for implementing the described subject technical solutions are disclosed below. In order to simplify the disclosure, the following describes the specific examples of each component and arrangement, of course, these are only examples, not limiting the protection scope of the present invention.

[0039] In addition, it should be understood that such as "one embodiment", "an embodiment", and / or "some embodiments", "one or more embodiments" mean a certain aspect related to at least one embodiment of the present application. Characteristic, structure or characteristic. Therefore, it should be emphasized and noted that references to "an embodiment" or "an embodiment" or "some embodiments" or "one or more embodiments" two or more times in different places in this specification do not Not necessarily referring to the same embodiment. In addition, certain features, structures or characteristics of one or more embodiments of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com