Self-snow-cleaning skylight of new energy automobile

A new energy vehicle and sunroof technology, which is applied in vehicle cleaning, vehicle maintenance, vehicle parts, etc., can solve the problems of driver's driving experience, affecting the lighting in the car, and inconvenient manual cleaning of snow on the sunroof, so as to promote snow melting , Improve snow clearing effect and good lighting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

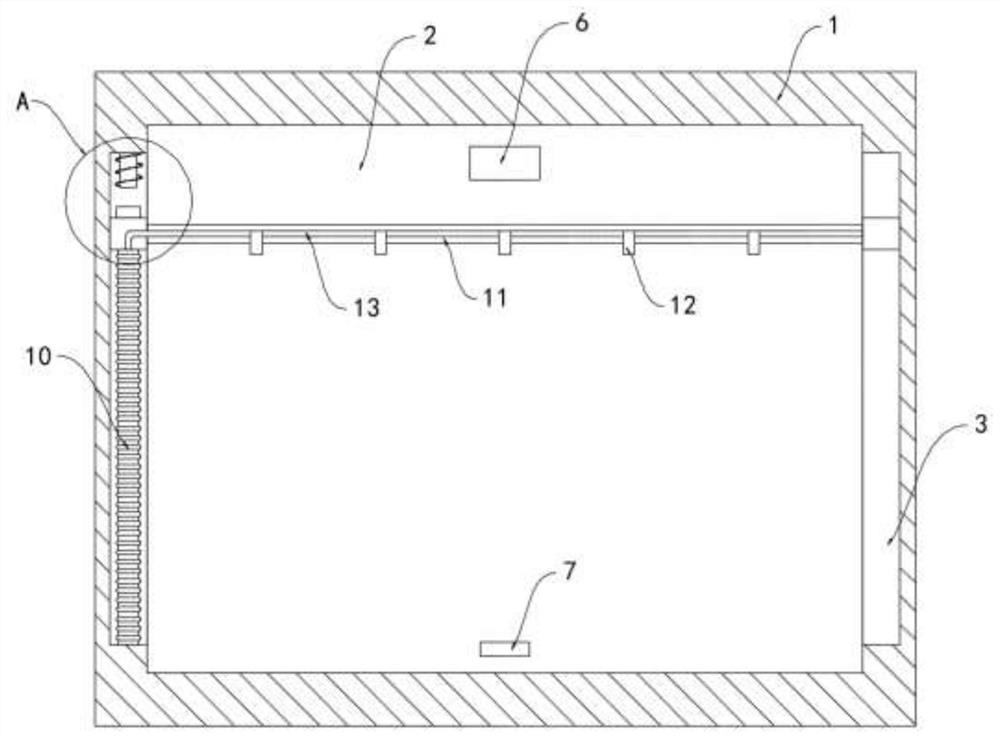

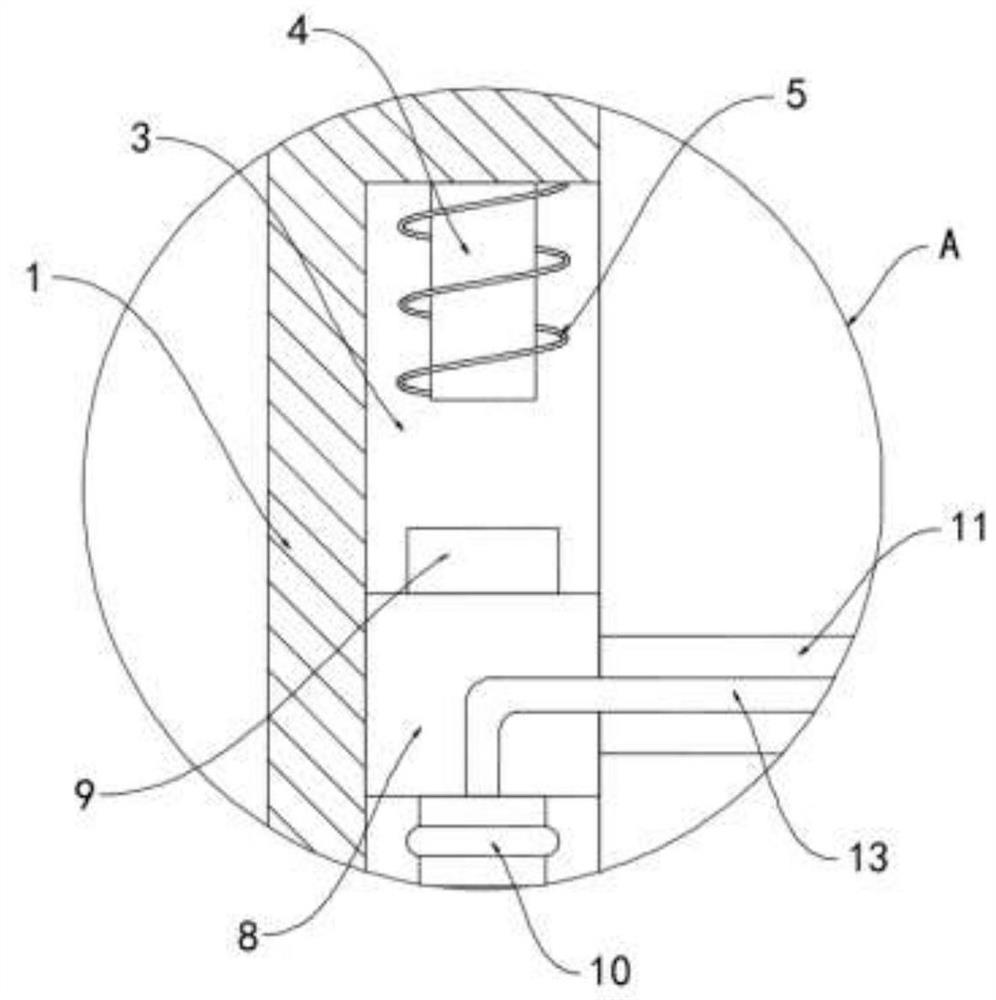

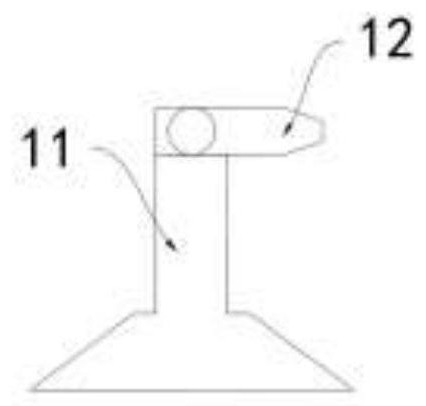

[0022] Such as Figure 1-3 As shown, a self-clearing sunroof of a new energy vehicle includes a frame body 1 and a skylight glass plate 2 installed in the frame body 1, and a chute 3 is opened on the inner ring side wall of the frame body 1, and the top of the chute 3 An electromagnet 4 is fixedly installed on the surface, and a spiral coil 5 is arranged around the electromagnet 4. A ceramic temperature difference sheet 6 and a photosensitive resistor 7 are embedded in the skylight glass plate 2. The positive and negative poles of the ceramic temperature difference sheet 6 pass through the photosensitive resistor 7 and the spiral Both ends of the coil 5 are electrically connected, a slider 8 slides in the chute 3, the upper end of the slider 8 is fixedly connected with a permanent magnet block 9, and the lower end of the slider 8 is fixedly connected with the bottom surface of the chute 3 through an elastic bellows 10, The surface of the skylight glass plate 2 is provided with...

Embodiment 2

[0030] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the slider 8 and the snow cleaning strip 11 are both made of heat-conducting metal materials, and the inner wall of the chute 3 is equipped with a friction plate 14 that is in contact with the slider 8 .

[0031] In this embodiment, when the slider 8 slides in the chute 3, it rubs against the friction plate 14 and generates heat, and the heat is conducted by the slider 8 and the snow strip 11 to the snow accumulation on the surface of the skylight glass plate 2, further Promote snow melting and facilitate snow removal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com