Dense-medium rapid-sinking water treatment system and method

A water sinking and water treatment technology, applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of low flocculation and sedimentation efficiency, large mine water treatment area, and underground treatment Problems such as backward technology and equipment development, to achieve the effects of easy monitoring and management, saving medicine costs, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0068] Specific embodiment 1: certain mine highly turbid mine water

[0069] When the concentration of PAM is 1.0mg / L and the dosage of micro-sand is 3g / L, the turbidity of the water after settlement is measured at different concentrations of PAC for high turbidity water samples. For experimental data, see image 3 . The experimental results show that the concentration of PAC has a significant effect on the turbidity of mine water. When the concentration of PAC is less than 70mg / L, as the concentration of PAC increases, the removal efficiency of mine water turbidity is higher. When the PAC concentration is greater than 70mg / L, as the PAC concentration increases, the mine water turbidity removal efficiency tends to decline. When the PAC mass concentration is low, it is difficult to settle because it is difficult to form flocs or the flocs are small, and the density is close to water. Therefore, the removal effect of suspended solids is poor, resulting in a low removal rate o...

specific Embodiment 2

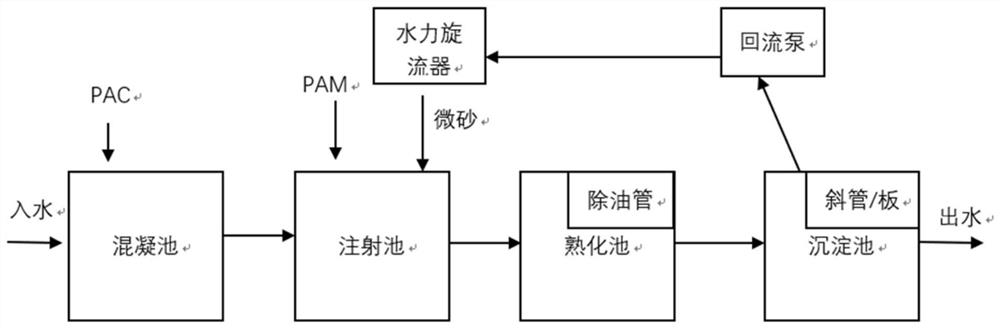

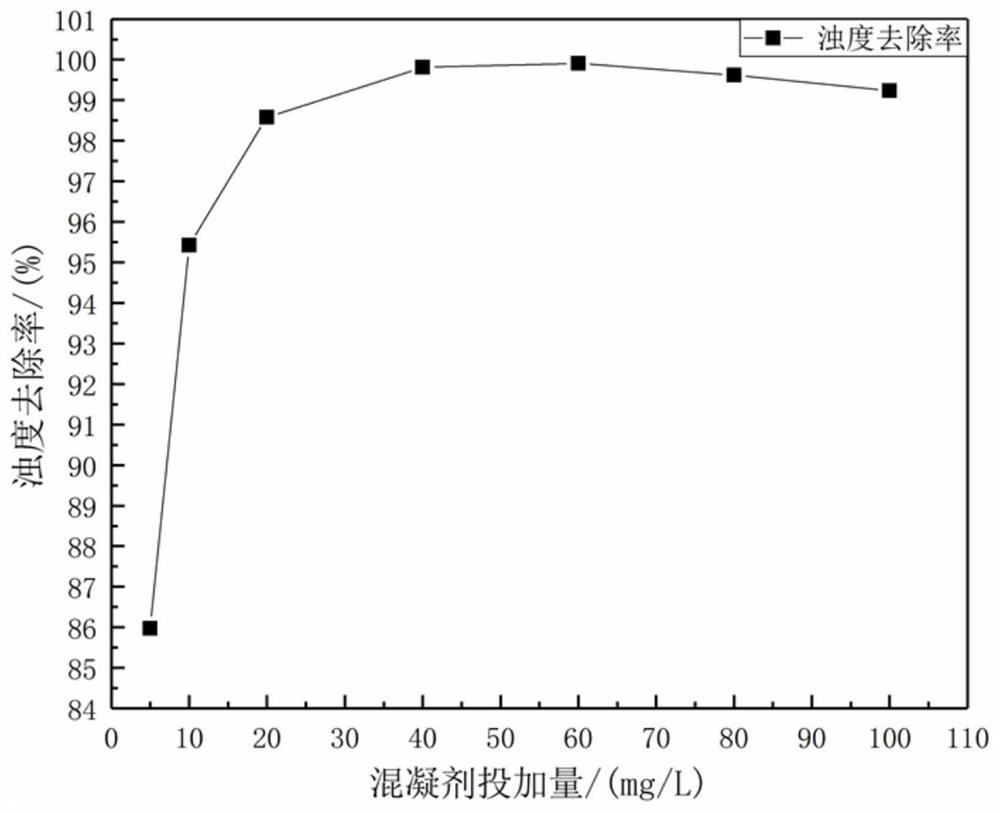

[0071] Specific embodiment 2: low turbidity waste water

[0072] When the concentration of PAM is 0.2mg / L and the dosage of fine sand is 2g / L, the water samples of the South-to-North Water Diversion are loaded and flocculated. The turbidity of the water was measured, and the experimental results are shown in Figure 5 . Overall, the influence trend of different PAC concentrations on the pollution of low-turbidity wastewater was consistent with that of high-turbidity wastewater. Within a certain range, the higher the PAC concentration, the higher the pollutant removal efficiency. When the dosage of PAC is small, PAC and wastewater will form larger particles, and the removal effect will be poor. With the increase of the dosage, the aluminum ions (Al3+) produced by the hydrolysis of PAC broke the charge balance state of the colloid, accelerated the alum flower to become larger and heavier, and the removal rate gradually increased. When the concentration exceeds a certain leve...

Embodiment 3

[0074] Embodiment 3: fly ash, the impact of fly ash particle size on treatment effect

[0075] The loading flocculation process has strict requirements on the particle size of the loading medium. In the micro-sand loading flocculation, the diameter of the micro-sand is 60-140μm. The particle size range of fly ash is relatively large, between 0.5-300μm, so it is necessary to screen the appropriate particle size of fly ash.

[0076] The fly ash used in the experiment was sieved, the sieve meshes were 100, 150, 200 and 325 mesh respectively, and the fly ash particle sizes of 0-45, 45-75, 75-106, 106-120, 120- 150 and >150μm. Take water samples from 6 beakers, adjust the pH value to 8, and add 20mg / L of PAC and 1g / L of fly ash with different particle sizes under rapid stirring conditions (because fly ash can promote flocculation and act as a flocculant Therefore, it is selected to be added together with PAC), and then 0.5mg / L of PAM is added under slow stirring conditions. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap