Automatic shoulder strap threading machine and shoulder strap buckle threading method

A technology of automatic threading and shoulder straps, which is applied in the direction of cloth feeding mechanism, sewing machine components, textiles and papermaking, etc., which can solve the problems of long cycle, unguaranteed product quality, and increased manual error rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

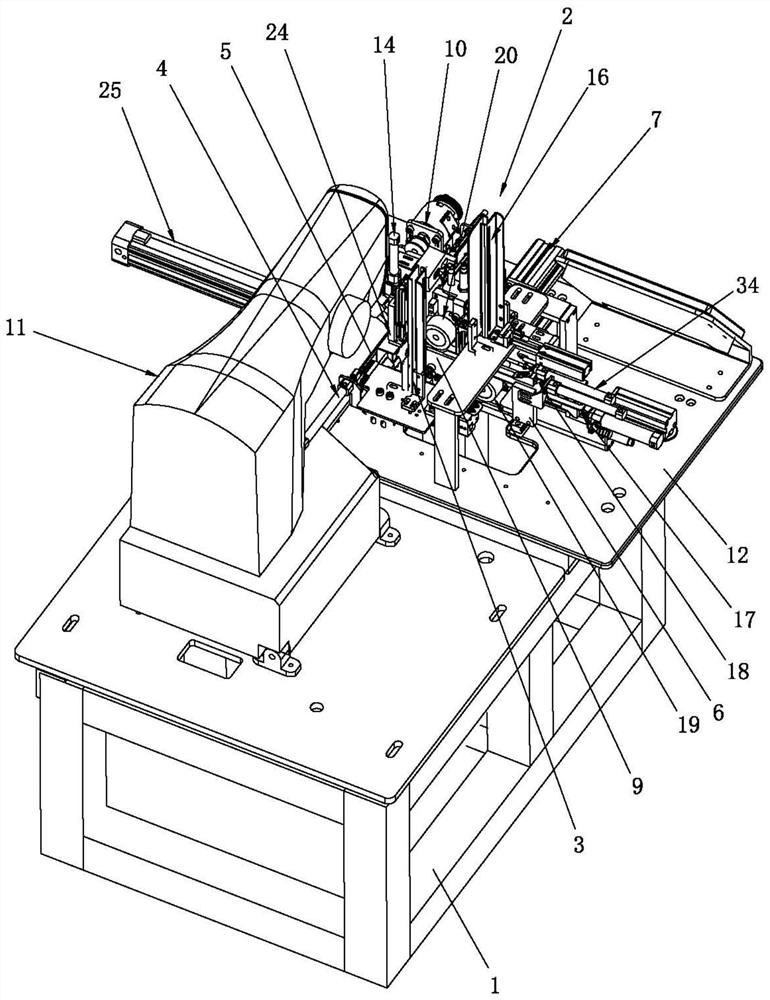

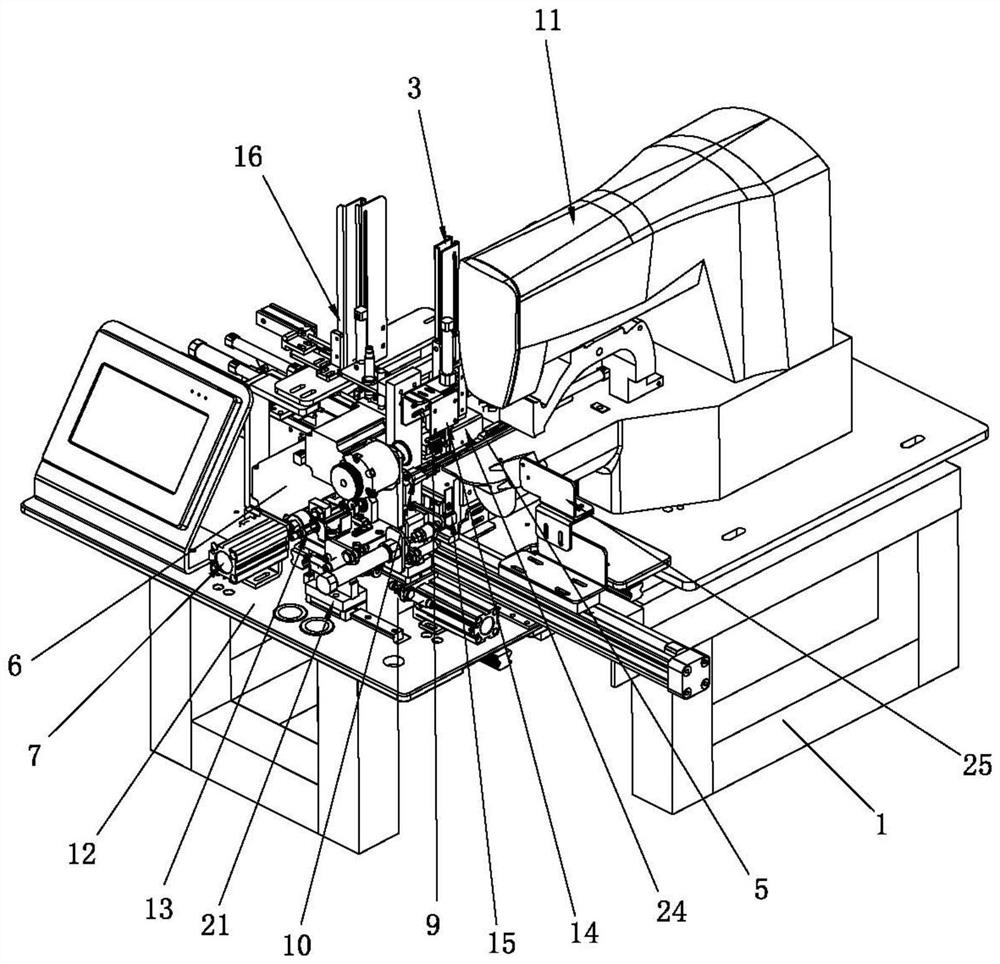

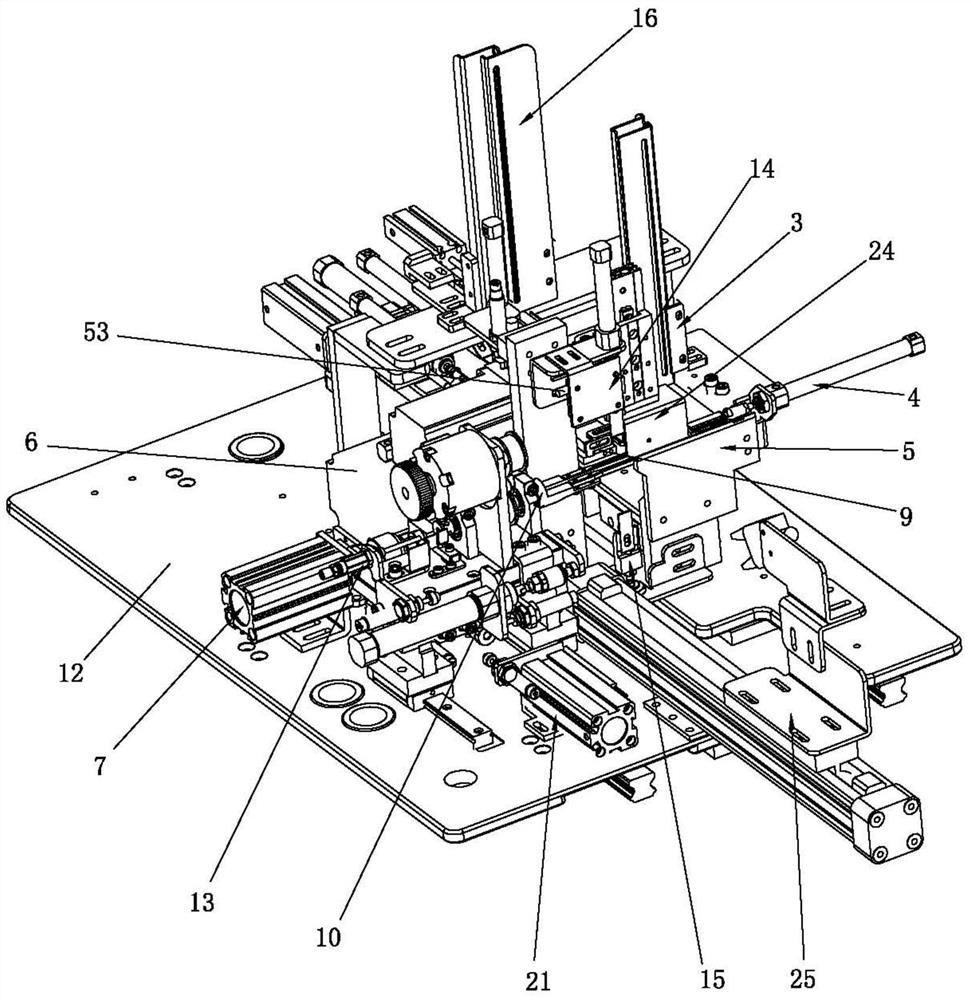

[0042] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

[0043] Such as Figure 1 to Figure 9 As shown, an automatic shoulder belt threading machine provided by the present invention includes a machine platform 1, a sewing machine 11 installed on the machine platform 1, a base 12 slidingly connected to the machine platform 1, and a wearing belt installed on the base 12. Button machine 2, described threading button machine 2 comprises for 8 button device 3, sends 8 button mechanism 4, is positioned at the 8 button guide rail 5 of one side of sewing machine 11, is slidably connected to the mobile seat 6 of base 12, is installed on the base Seat 12 is also used to drive the first moving drive mechanism 7 that mobile seat 6 moves, the shoulder strap g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com