Automatic pile gripper and control method for automatic pile holding

An automatic and pile driver technology, which is applied in the direction of sheet pile walls, buildings, foundation structures, etc., can solve the problems of abandoned piles, failure to meet the use requirements, deflection of piles driven into underwater mud, etc., to improve work efficiency , The braking effect is remarkable, and the effect of ensuring verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

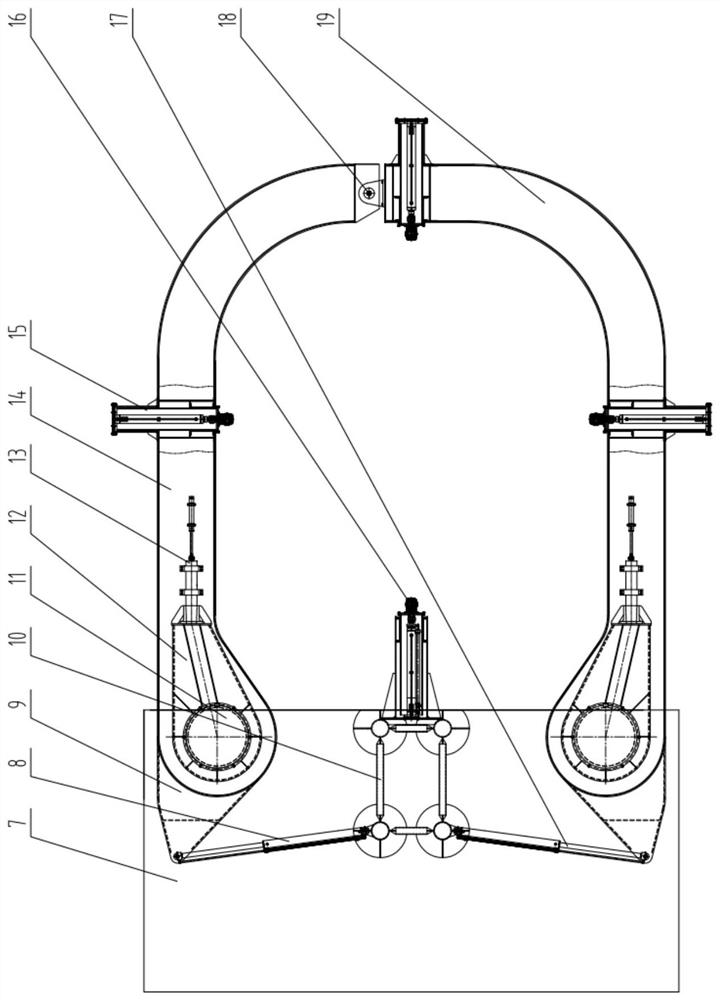

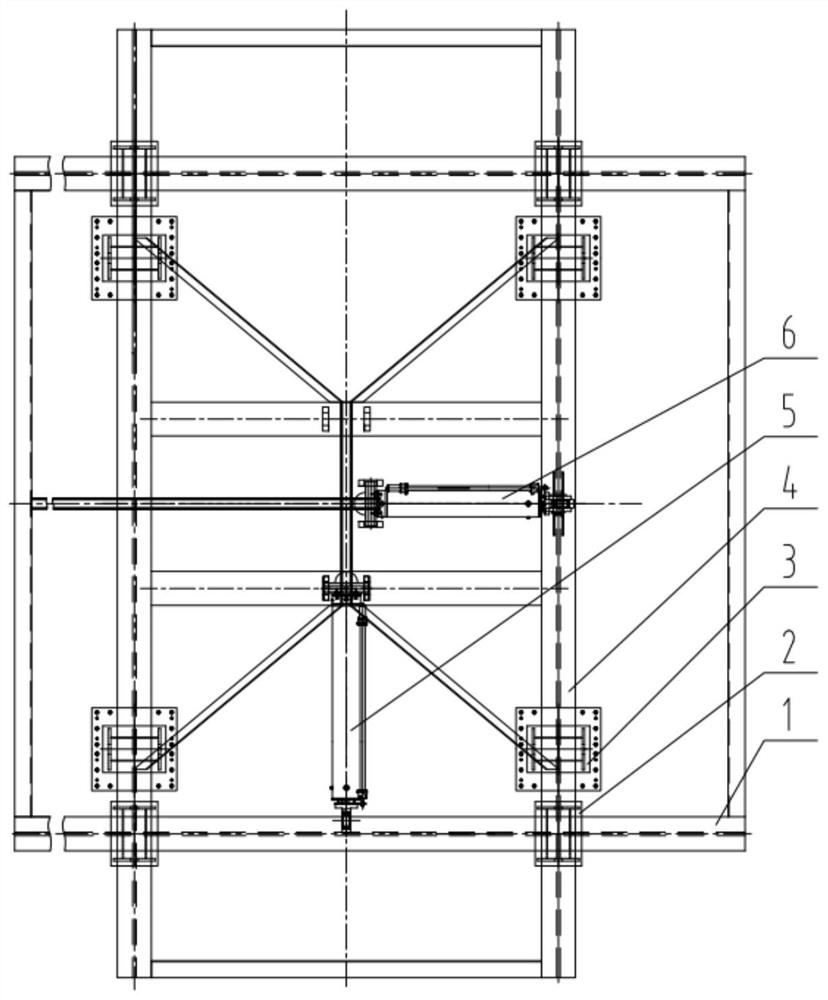

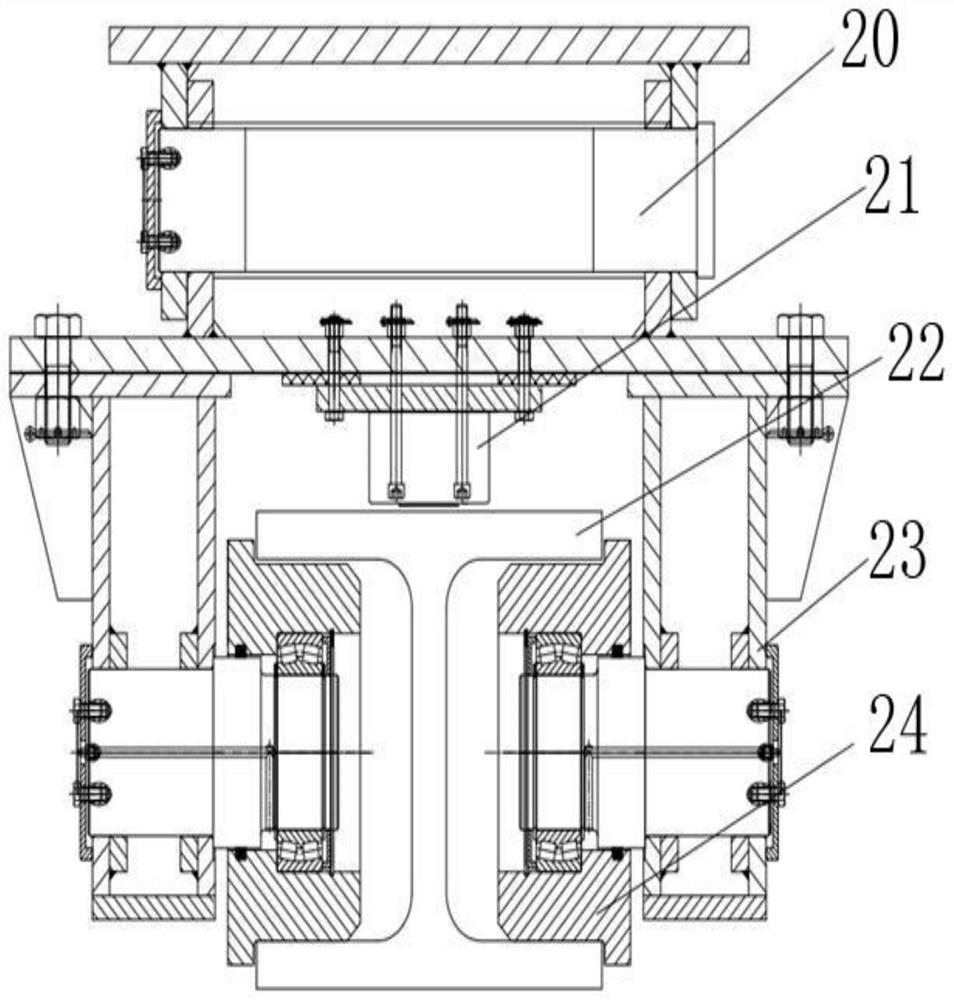

[0029] Attached below Figure 1-7 The present invention is further illustrated with specific examples.

[0030] like Figure 1-3 Shown, a kind of automatic pile holding machine comprises:

[0031] The walking chassis 7 is set as a platform structure;

[0032] Adjustable supporting device supports and fixes the walking chassis 7, which can be adjusted vertically and horizontally in the horizontal direction;

[0033] A pair of columns 11 are vertically fixed on the walking chassis 7;

[0034] The left arm 14 of the arm claw is set on one of the uprights 11 in a horizontal rotation, and is equipped with a horizontal rotation drive mechanism to drive it to rotate;

[0035] Arm claw right arm 19 cooperates with arm claw left arm 14 to embrace stake 26 together, and arm claw right arm 19 is sleeved on the other column 11 horizontally, and is configured with a horizontal rotation drive mechanism that drives its rotation.

[0036] Among them, the adjustable support device include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com