Piston device and method for reactivating ineffective piezometer tube

A piezometric tube and piston technology, which is applied to components, lifting devices, cleaning methods and utensils of a pumping device for elastic fluids, can solve the problems of difficult handling of piezometric tubes, insensitive water level changes, etc. The effect of secondary or multiple burial, improving the scope of application, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

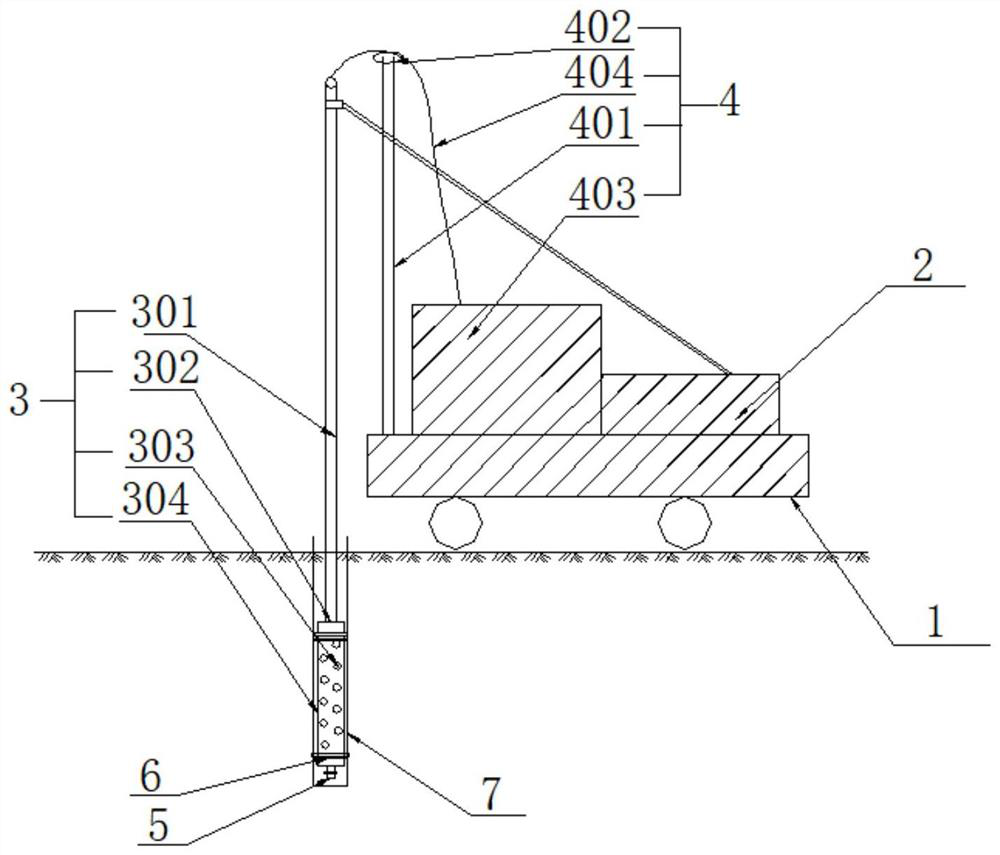

[0053] Such as Figure 1-2 As shown, a piston device for resurrecting a failed piezometric tube provided in this embodiment includes:

[0054]Support 1, the support 1 can be a trolley or other plate-shaped support, which can be used to place other components;

[0055] A water pump 2, the water pump 2 is installed on the support member 1, and the water pump 2 is used to provide pressure;

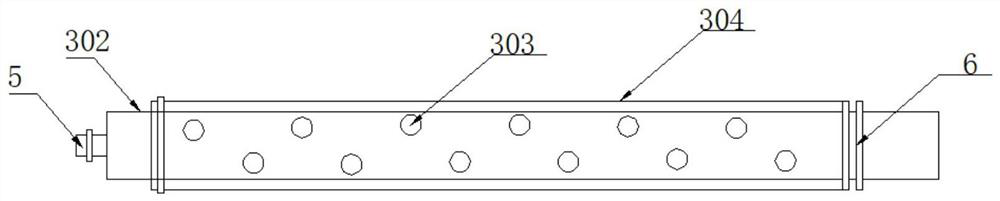

[0056] Stamping unit 3, the stamping unit 3 stretches into the pressure measuring tube, and the stamping unit 3 communicates with the water pump 2, the outer wall of the stamping unit 3 is in contact with the inner wall of the pressure measuring tube, so that when the stamping unit 3 moves up and down, it can Complete the flushing of the piezometer;

[0057] Lifting unit 4, the lifting unit 4 is installed on the support 1, and the lifting unit 4 is connected to the upper end of the stamping unit 3, the lifting unit 4 in the embodiment of the present application is a power part, driving the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com