Hanging type cable tunnel inspection robot

A cable tunnel and hanging technology, which is applied in the direction of instruments, manipulators, non-electric variable control, etc., can solve the problems of wheeled or tracked robots unable to walk, water accumulation, etc., and achieve the effect of flexible charging methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

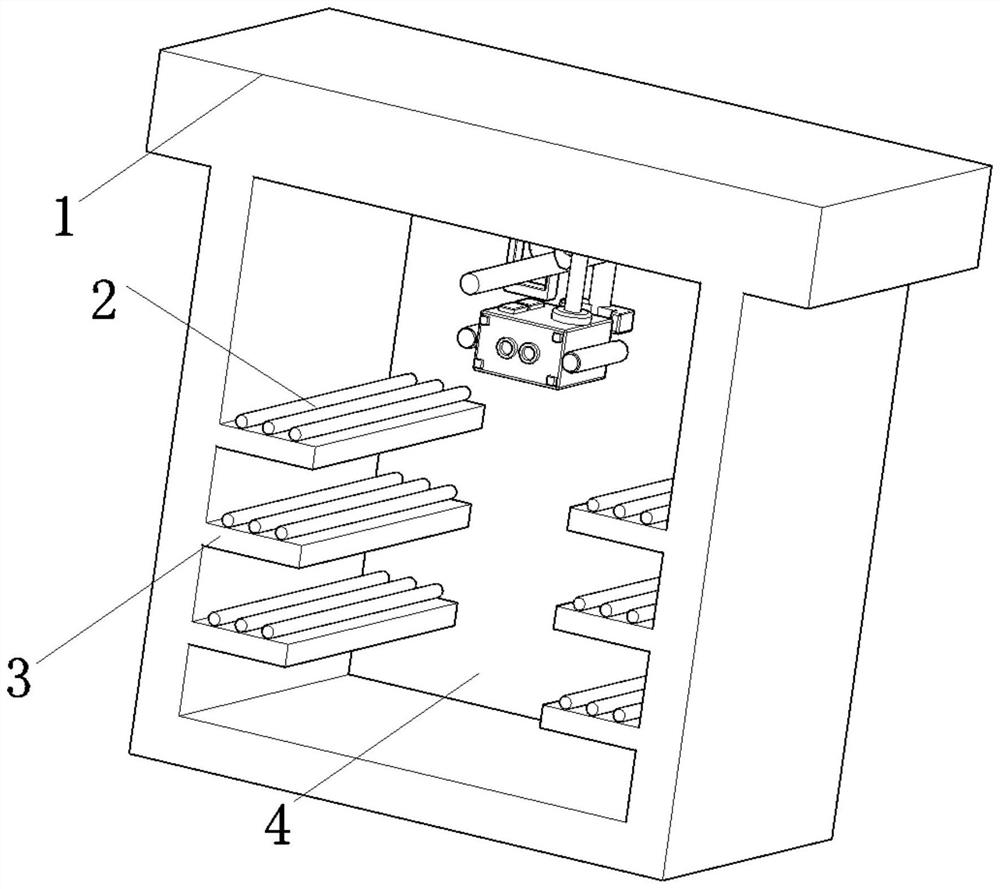

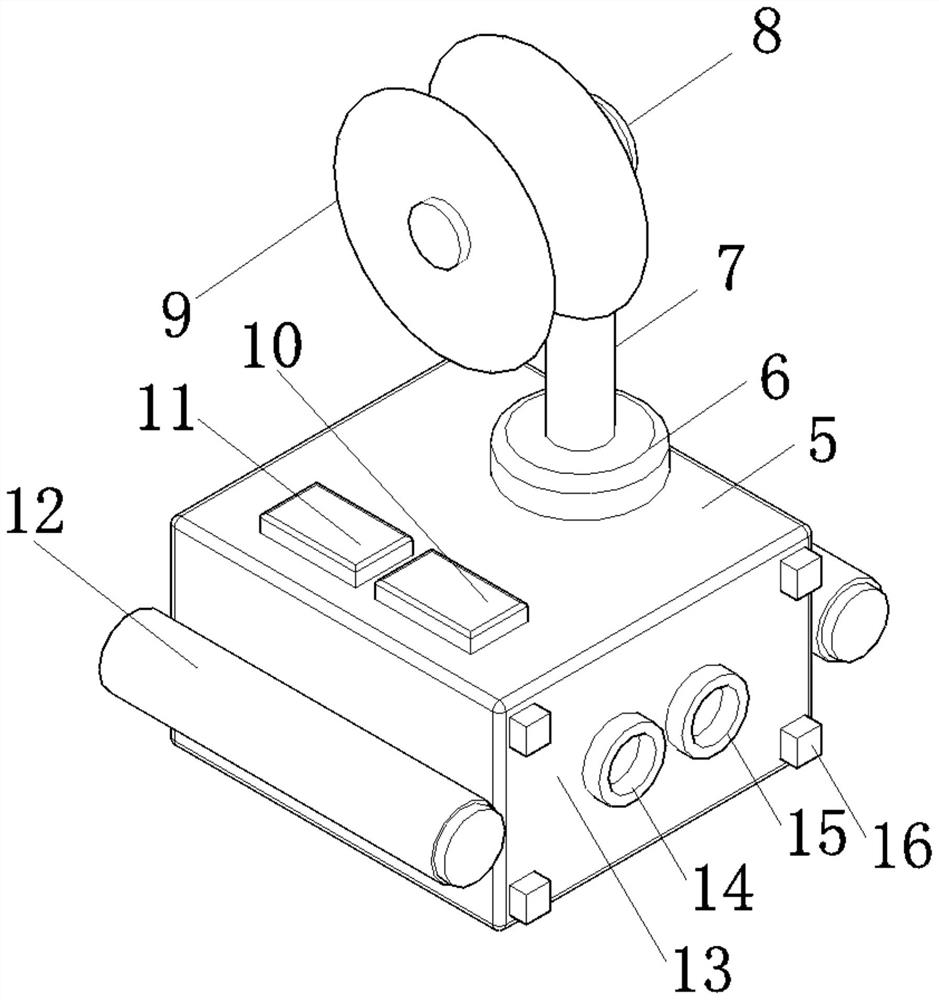

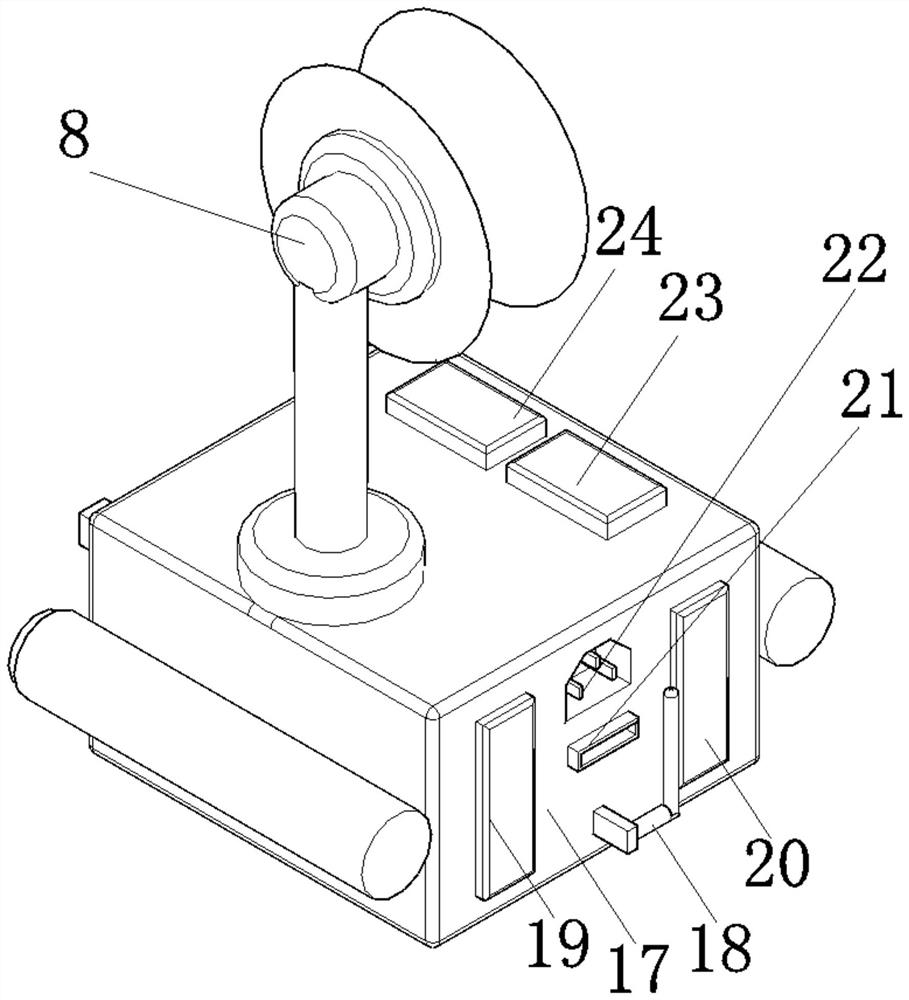

[0043] like Figure 1-10 As shown, it shows the specific implementation of the present invention, as shown in the figure, the hanging type cable tunnel inspection robot disclosed by the present invention is used to inspect the tunnel 4 where cables are arranged, and includes a fixed assembly, a charging assembly and a host components;

[0044] The fixing assembly includes a fixing rod 35, the top of the fixing rod 35 is fixedly installed on the top surface of the tunnel 4, and the bottom of the fixing rod 35 is fixed to a steel wire rope 37 extending along the tunnel;

[0045] The charging assembly is fixedly installed at one end of the inspection port of the tunnel 4; the charging assembly includes a hanging tube 32, and the bottom of the hanging tube 32 is a charging base 31, and the side of the charging base 31 facing the host assembly is symmetrically provided with a zero line terminal 33 and a live line terminal 34 on both sides ;

[0046] The host assembly includes a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com