Matching tool box for on-site metallographic detection

A metallographic detection and toolbox technology, applied in the direction of manufacturing tools, tool storage devices, etc., can solve the problems of disorder, insufficient battery life, insufficient power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] This patent is a matching toolbox for on-site metallographic detection.

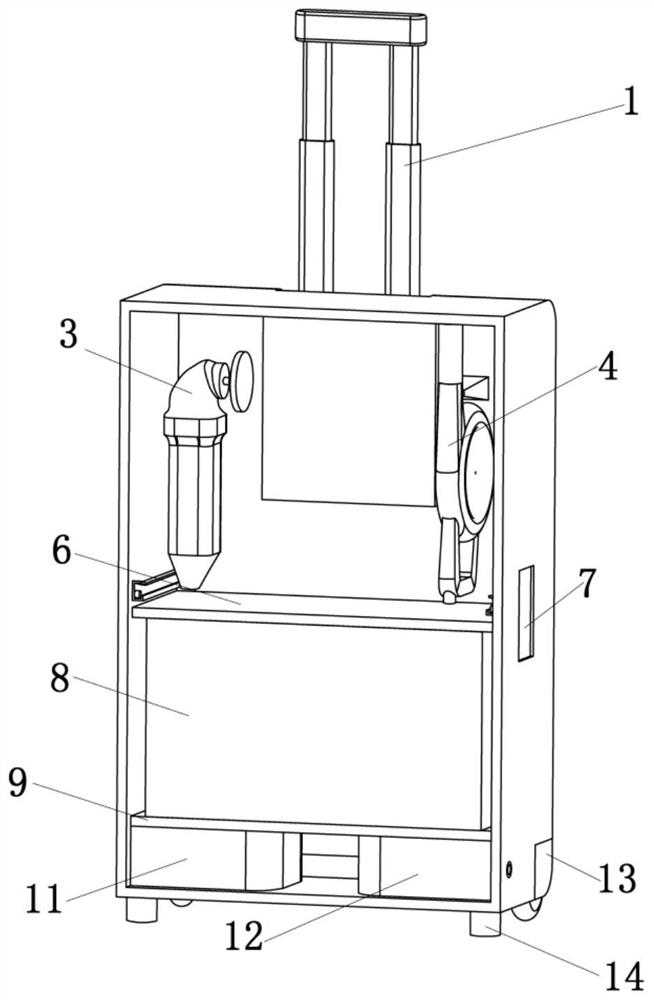

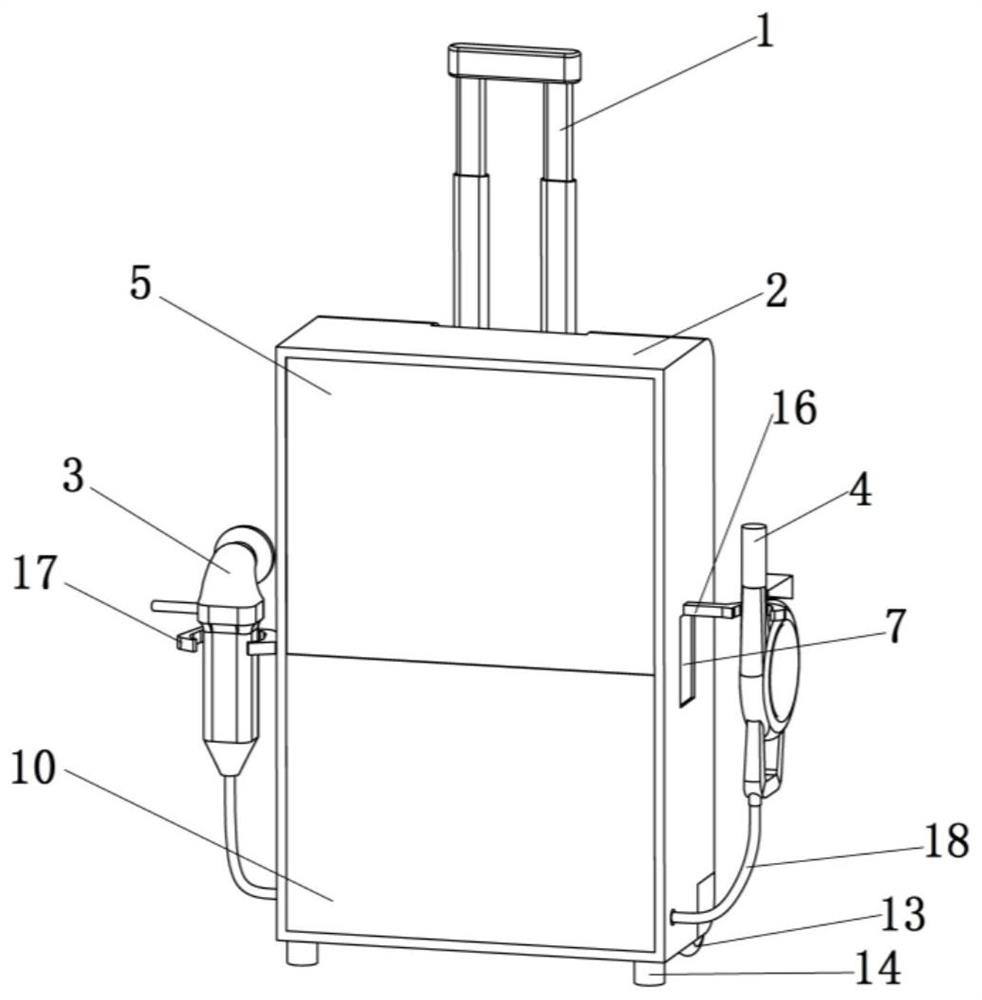

[0025] Such as figure 1 , Figure 4 As shown, the device is mainly composed of a pull rod 1, a casing 2, a hook groove 7, a roller 13, a foot 14 and an outlet 15 to form an external part. Its interior is mainly divided into three layers, which are separated by partition A6 and partition B9, which are respectively the upper tool storage area, the middle power supply area, and the lower cord reel area.

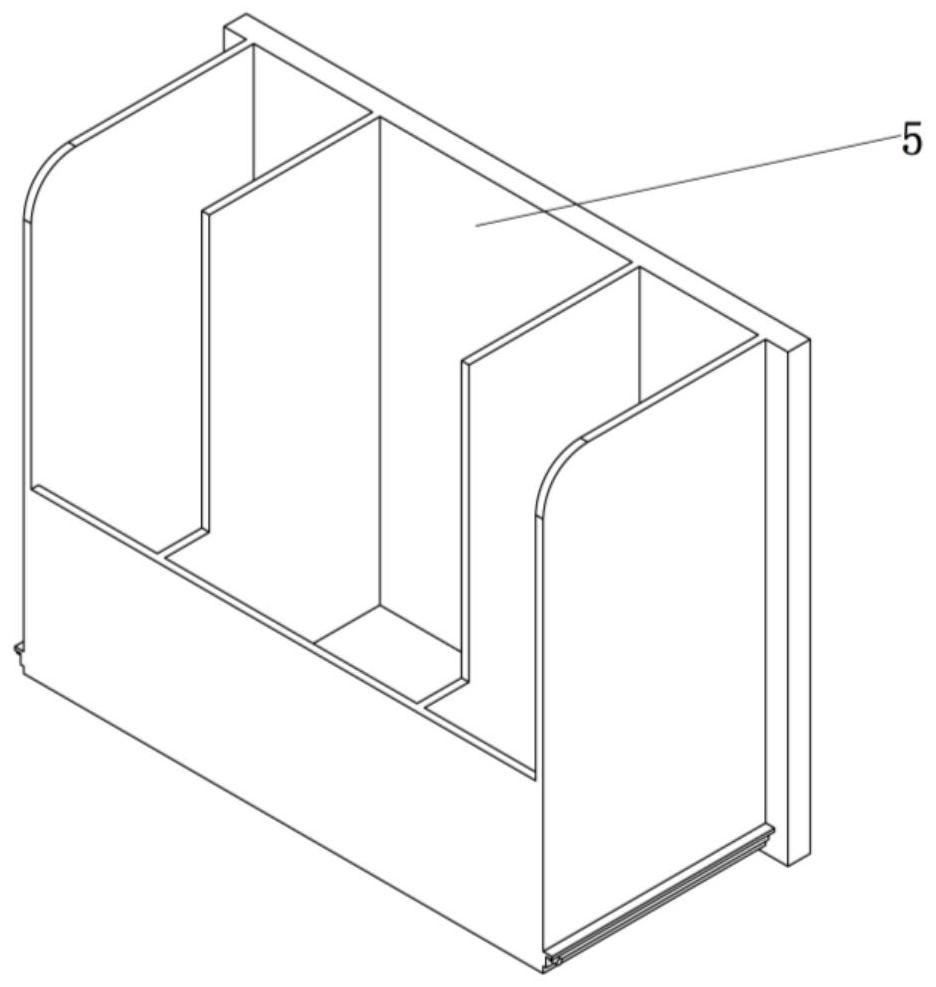

[0026] Such as figure 2 As shown, the main part of the upper tool storage area is the drawer 5, which is divided into three storage areas, the storage areas on both sides are used to store the angle grinder 3 and the suction blower 4, and the middle storage area is used to store the portable metallographic Microscopes and other sundries. Both the angle grinder 3 and the blower 4 adopt a 12V DC power supply. The middle power supply area is a large-capacity 12V DC lithium battery 8, which can pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com