Unitary linear point-by-point analysis method, system and device for standardized residual error test method

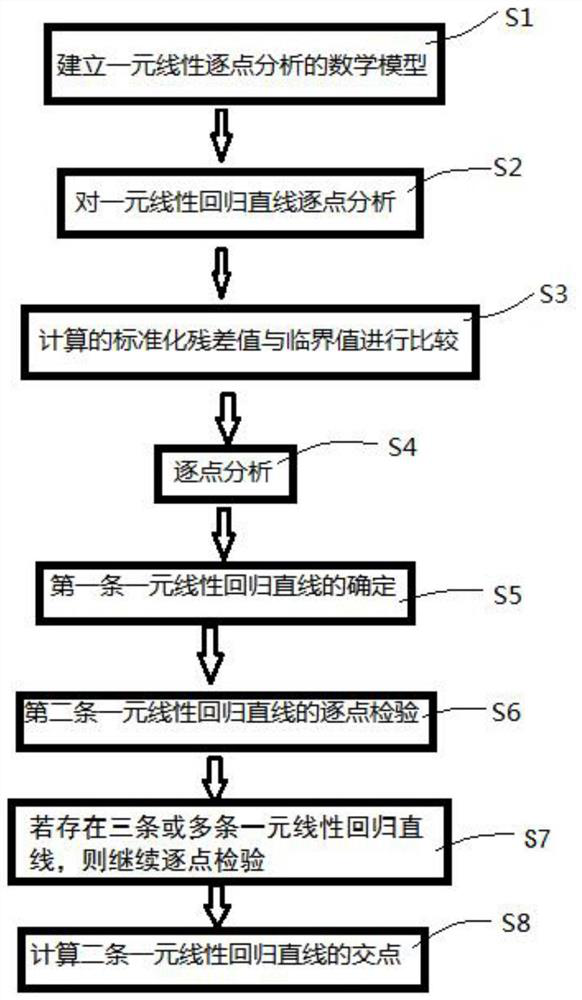

A technology for standardizing residuals and analysis methods, which is applied in the field of chemical analysis and can solve problems such as troublesomeness, difficulty in drawing conductometric titration, and inability to automatically determine the titration end point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

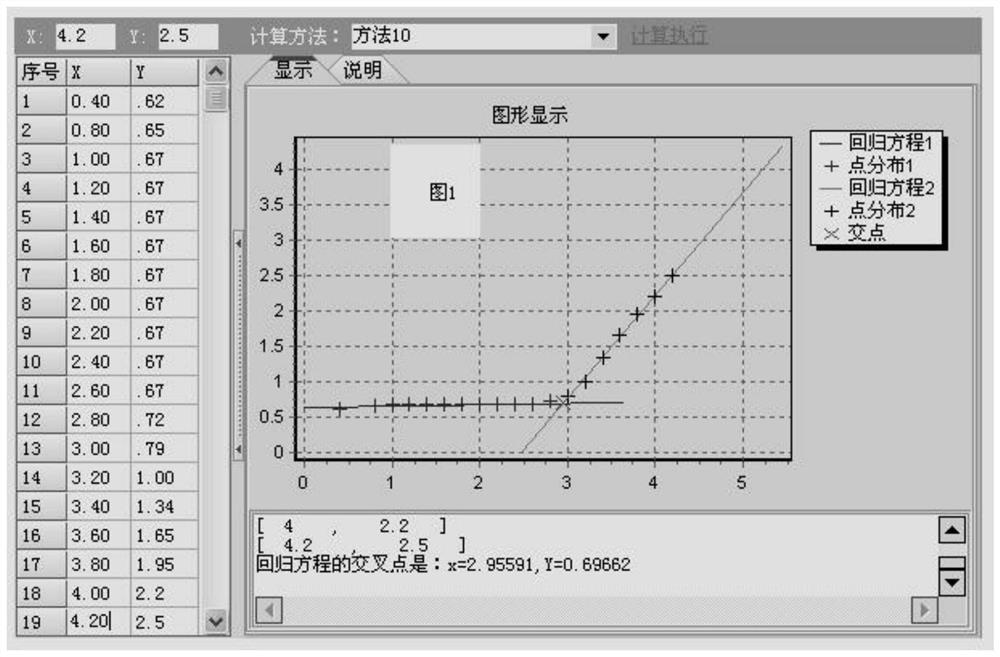

[0196] Such as figure 1 As shown, the point-by-point analysis example of two unary linear regression lines

[0197] The standardized residual test method of unary linear point-by-point analysis is often used in the analysis of two unary linear regression lines. The following is a point-by-point analysis of two linear regression lines in the shape of "┛"

[0198] (1) Experimental data set

example 1

[0199] Example 1: A set of experimental data sets are shown in Table 2-1:

[0200] Table 2-1 Example of α-acid determination in hops

[0201]

[0202] (2) One-variable linear point-by-point analysis

[0203] Starting from N=4, a linear regression calculation was performed on the first 4 sets of data. get:

[0204] the y 4 =a+bx=0.5954+0.06714x(2-1)

[0205] r 1 =0.9706

[0206] Check the correlation coefficient critical value table r 0.05,4 , is 0.950, and the actual calculated r value is 0.9706, which is greater than 0.950, indicating that the established regression equation (2-1) has a significant correlation, and the unary linear regression equation is meaningful.

[0207] Then the calculation of residuals and standardized residuals is performed. The results are shown in Table 2-2.

[0208] Table 2-2 Residual values and standardized residuals when N=4

[0209]

[0210]

[0211] It can be seen from Table 2-2 that the absolute value of the actual calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com