Organic light-emitting display substrate, preparation method thereof and organic light-emitting display device

A technology of light-emitting display and organic light-emitting devices, which is applied in the fields of organic semiconductor devices, photovoltaic power generation, semiconductor/solid-state device manufacturing, etc., and can solve problems such as peeling off of the packaging layer, failure of the packaging layer, and reduced reliability of display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

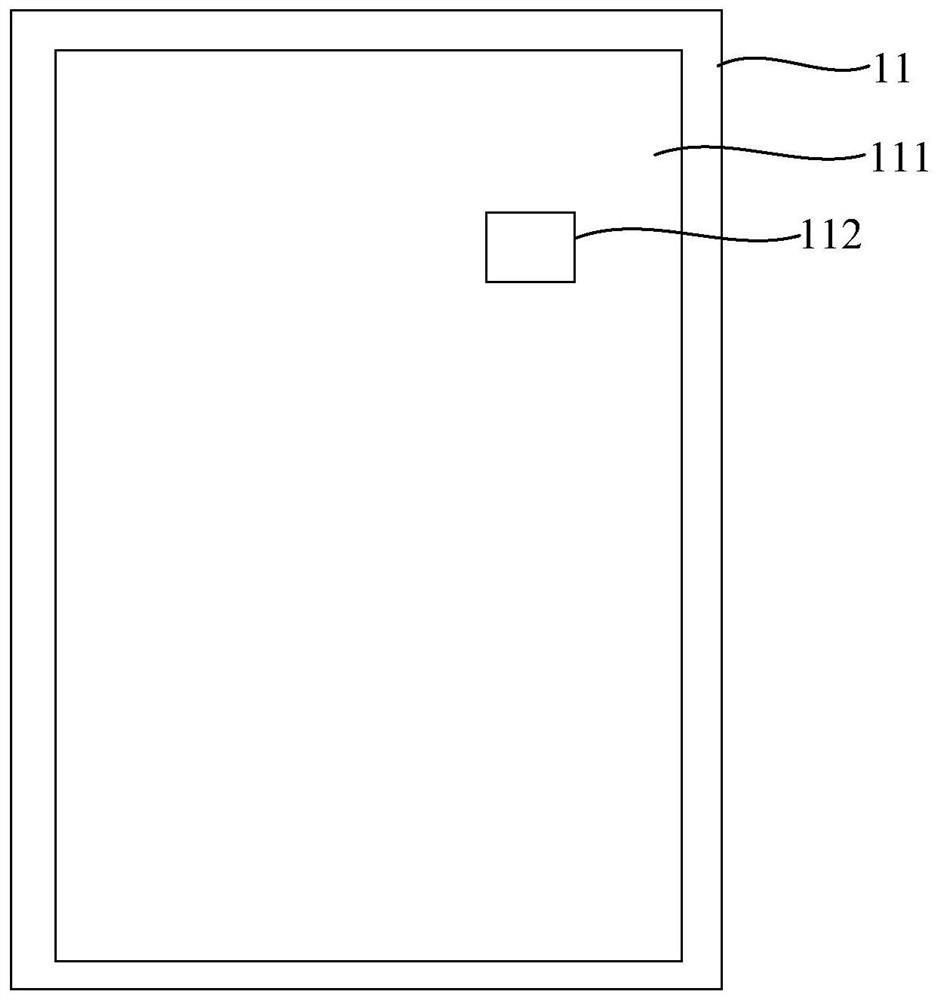

[0070] An embodiment of the present invention provides a method for preparing an organic light emitting display substrate. Such as Figure 4 As shown, the organic light emitting display substrate includes a display area 411 and an opening area 412 located in the display area 411 . The preparation method of the organic light-emitting display substrate, such as Figure 9 As shown, the following steps 901-906 are included:

[0071] In step 901 , the flexible substrate 51 is formed on the support substrate 54 ; the support substrate 54 supports the flexible substrate 51 ; the flexible substrate 51 includes an opening 55 located in the opening area 412 .

[0072] In this embodiment, the supporting substrate is a rigid supporting substrate, which supports the flexible substrate. For example, the supporting substrate may be a glass substrate, but is not limited thereto.

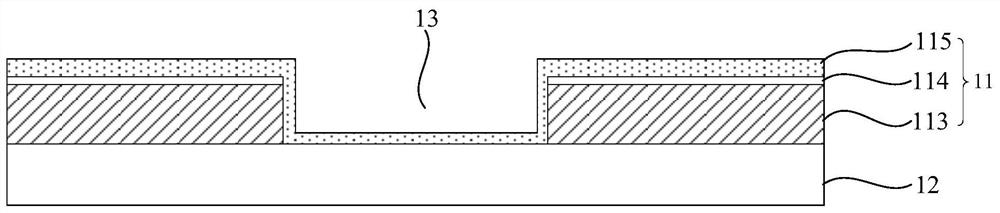

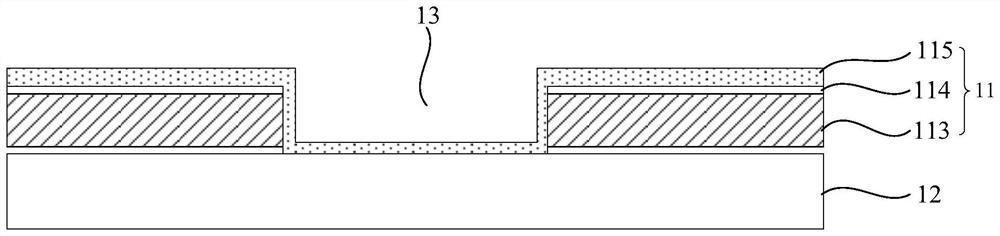

[0073] In this example, if Figure 10 As shown, the opening 55 is a blind hole. The distance between the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com