A method for modifying the compressive properties of PBO fibers

A fiber and performance technology, applied in the field of PBO fiber modification, can solve the problems of microfiber peeling damage, poor compression performance, etc., and achieve the effect of reliable quality, stable process and enhanced interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

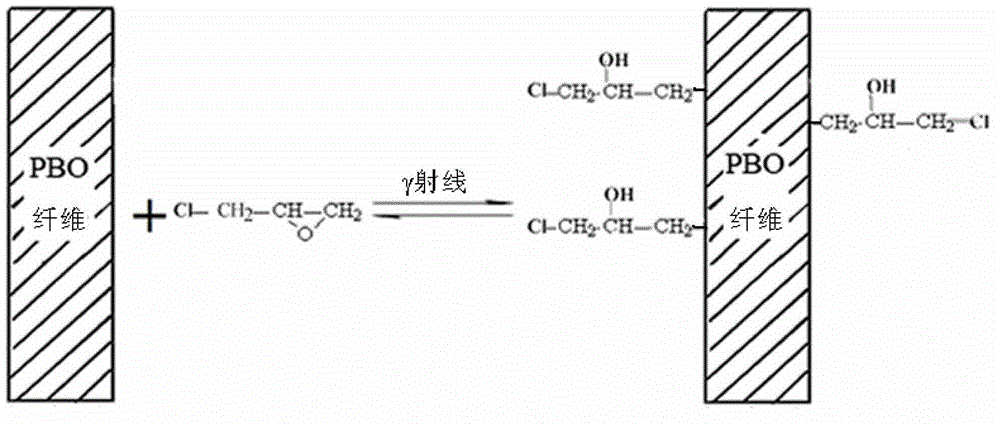

[0013] Embodiment 1: This embodiment provides a method for modifying the compression properties of PBO fibers, which is specifically completed in the following steps:

[0014] 1. Under the protection of protective gas, use γ-rays to irradiate PBO fibers, wherein the irradiation dose is 36KGy-50KGy, and the irradiation dose rate is 5.9KGy / h-6.0KGy / h;

[0015] 2. Transfer the PBO fiber treated in step 1 into the solution of epichlorohydrin, soak for 2h-10h, and the modification of the compressive properties of the PBO fiber is completed.

[0016] The KGy mentioned in this embodiment is kilogray, which means the total amount of ionizing radiation absorbed by a substance.

[0017] The KGy / h mentioned in this embodiment is kilogray / h, which means the total amount of ionizing radiation absorbed by the material per hour.

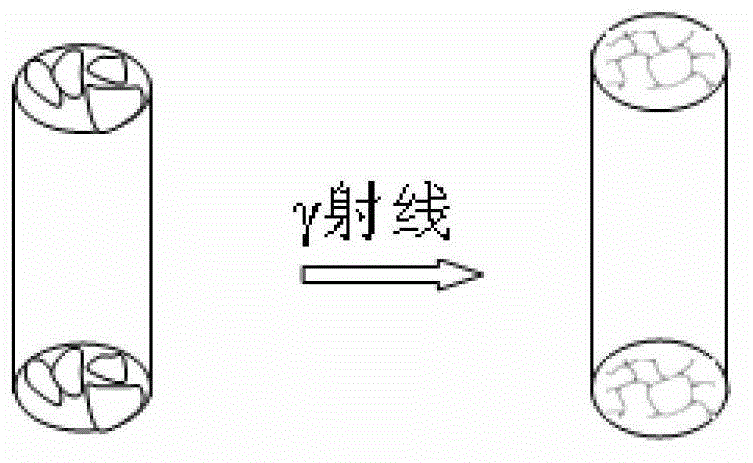

[0018] The gamma ray is used to irradiate the PBO fiber in step one described in this embodiment. Since the gamma ray is a kind of high-energy ray, in the interio...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the protective gas in Step 1 is nitrogen or a rare gas. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the γ-ray in the step one is 60 Co gamma rays. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com