A method for reducing the content of lithium impurities in high-nickel cathode materials

A positive electrode material, high-nickel technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of high cost and damage to the lattice stability of high-nickel materials, and achieve the effect of improving lattice stability and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

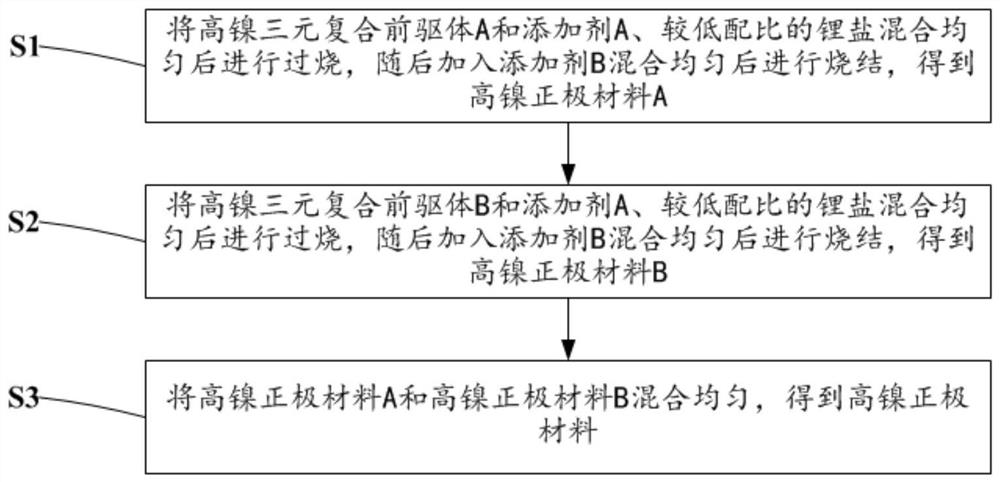

Method used

Image

Examples

Embodiment 1

[0031] With 1000g nickel-cobalt-aluminum molar ratio 88:7:5 particle diameter D50 is the nickel-cobalt-aluminum composite hydroxide precursor of 18um, and 1.81g Mg(OH) 2 And 473g lithium hydroxide monohydrate (molar ratio Li:Me=1.025:1) joins in the small-scale high-speed mixer, unloads after mixing 0.5h, packs in the sagger, burns in oxygen atmosphere 780 ℃ (overburning (calcination temperature 50°C) for 10h, then 500g of one-fired NCA and 2.86g of boron oxide were fired at 250°C for 6h to obtain a high-nickel cathode material A.

[0032] With 1000g nickel-cobalt-aluminum molar ratio 88:7:5 particle diameter D50 is the nickel-cobalt-aluminum composite hydroxide precursor of 2.3um, and 1.81g Mg(OH) 2 And 473g lithium hydroxide monohydrate (molar ratio Li:Me=1.025:1) joins in the small-scale high-speed mixer, unloads after mixing 0.5h, packs in the sagger, burns (overburned at 740 ℃ in oxygen atmosphere) (calcination temperature 40°C) for 10h, and then 500g of one-fired NCA an...

Embodiment 2

[0036] With 1000g nickel-cobalt-aluminum molar ratio 88:7:5 particle diameter D50 is the nickel-cobalt-aluminum composite hydroxide precursor of 18um, and 1.81g Mg(OH) 2 And 473g lithium hydroxide monohydrate (molar ratio Li:Me=1.025:1) joins in the small-scale high-speed mixer, unloads after mixing 0.5h, packs in the sagger, burns in oxygen atmosphere 810 ℃ (overburning (calcination temperature 80°C) for 10h, and then 500g of one-fired NCA and 2.86g of boron oxide were fired at 250°C for 6h to obtain a high-nickel cathode material.

[0037] With 1000g nickel-cobalt-aluminum molar ratio 88:7:5 particle diameter D50 is the nickel-cobalt-aluminum composite hydroxide precursor of 2.3um, and 1.81g Mg(OH) 2 And 473g lithium hydroxide monohydrate (molar ratio Li:Me=1.025:1) joins in the small-scale high-speed mixer, unloads after mixing 0.5h, packs in the sagger, burns in oxygen atmosphere 780 ℃ (overburning (calcination temperature 80°C) for 10h, and then 500g of one-fired NCA and...

Embodiment 3

[0040] With 1000g nickel-cobalt-aluminum molar ratio 88:7:5 particle diameter D50 is the nickel-cobalt-aluminum composite hydroxide precursor of 18um, and 1.81g Mg(OH) 2 And 473g lithium hydroxide monohydrate (molar ratio Li:Me=1.025:1) joins in the small-sized high-speed mixer, unloads after mixing 0.5h, packs in the sagger, burns (overburned at 760 ℃ in oxygen atmosphere) (calcination temperature 30°C) for 10h, and then 500g of one-fired NCA and 2.86g of boron oxide were fired at 250°C for 6h to obtain a high-nickel cathode material A.

[0041] With 1000g nickel-cobalt-aluminum molar ratio 88:7:5 particle diameter D50 is the nickel-cobalt-aluminum composite hydroxide precursor of 2.3um, and 1.81g Mg(OH) 2 And 473g lithium hydroxide monohydrate (molar ratio Li:Me=1.025:1) joins in the small-sized high-speed mixer, unloads after mixing 0.5h, packs in the sagger, burns in oxygen atmosphere 730 ℃ (overburning (calcination temperature 30°C) for 10h, and then 500g of one-fired NC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com