Line short-circuit fault automatic detection and removal device

An automatic detection and line short-circuit technology, which is applied to emergency protection circuit devices, substation/switch layout details, electrical components, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

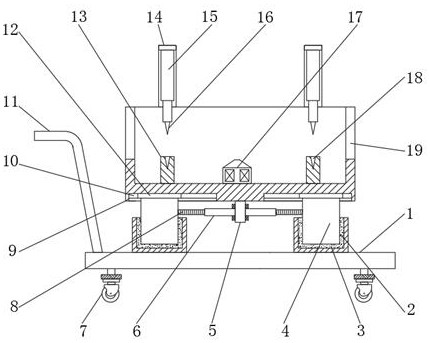

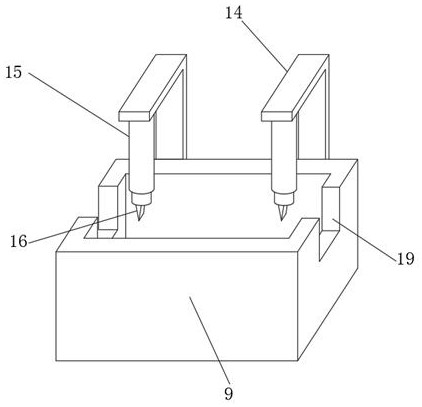

[0027] refer to Figure 1-2 , a device for automatic detection and removal of short circuit faults, comprising a base 1 and a detection box 9, the four corners of the outer wall of the top of the base 1 are fixedly connected with a fixed cylinder 3, and the inner wall of the fixed cylinder 3 is provided with an insulating sleeve 2, the insulating sleeve 2 is provided with a fixed column 4, the bottom outer wall of the detection box 9 is provided with a chute 10, and the inner wall of the chute 10 is slidably connected with a slide plate 12, the bottom outer wall of the slide plate 12 is fixedly connected with the top outer wall of the fixed column 4, and the detection box The inside of 9 is provided with a cutting mechanism, the bottom outer wall of the detection box 9 is provided with a fixing mechanism, and the four corners of the bottom outer wall of the base 1 are provided with universal wheels 7 .

[0028] The top outer wall of the base 1 is fixedly connected with a push ...

Embodiment 2

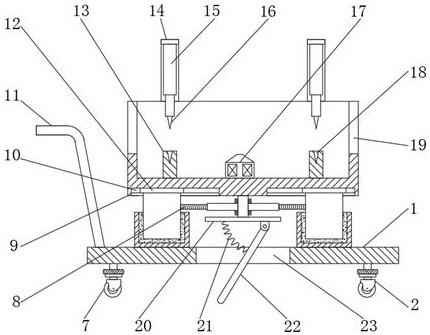

[0035] refer to image 3 , a device for automatic detection and removal of short circuit faults. Compared with Embodiment 1, this embodiment also includes a mounting plate 20 fixedly connected to the bottom outer wall of the fixing plate 5, and a grounding connection connected to the bottom outer wall of the mounting plate 20 through the ear socket. The rod 22 , the bottom outer wall of the mounting plate 20 and one side outer wall of the grounding rod 22 are connected by a spring 21 .

[0036] A fixing opening 23 is opened on the bottom outer wall of the base 1 .

[0037] Working principle: When in use, the grounding rod 22 is rotated on the bottom of the mounting plate 20 through the ear socket, and the spring 21 located between the mounting plate 20 and the grounding rod 22 makes the grounding rod 22 always in contact with the ground during the movement of the device, so that the device is always in contact with the ground. It is in a grounded state, which further improves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com