Low-voltage driving V-shaped linear ultrasonic motor

A linear ultrasonic motor, low-voltage drive technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of large friction loss, low efficiency, clamping device Complicated problems, to achieve low friction loss, reduce energy loss, and improve output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

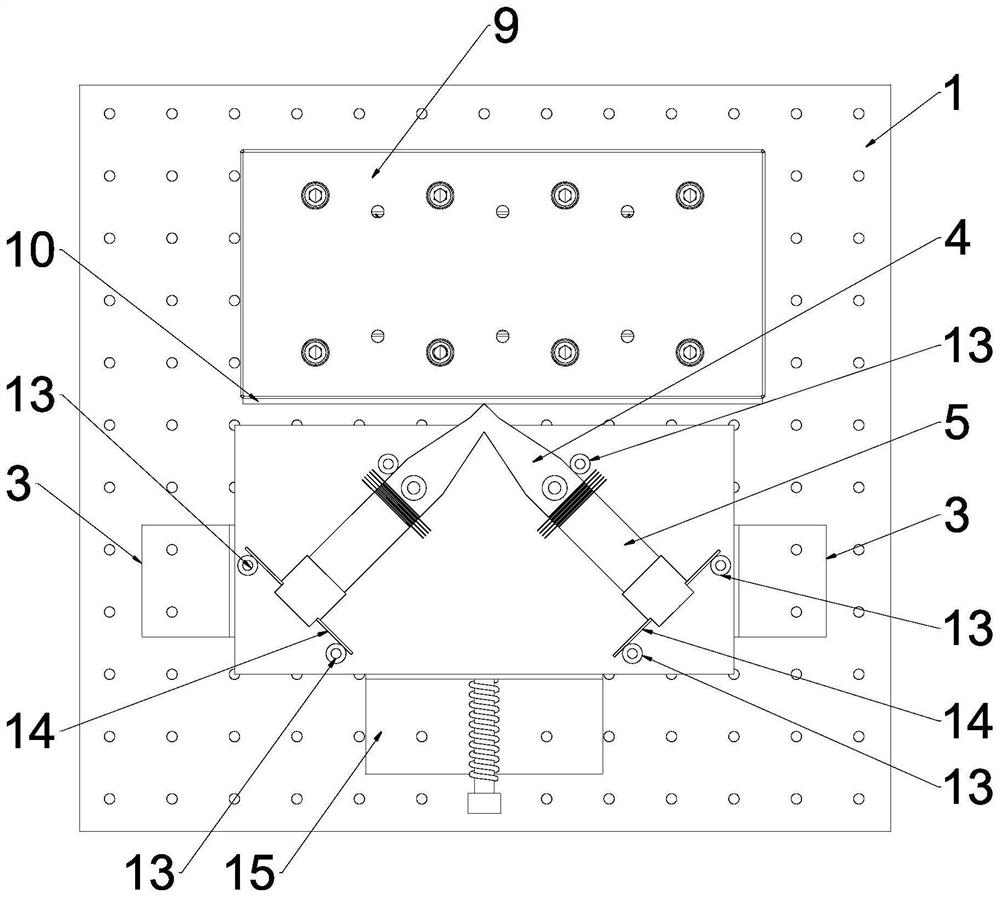

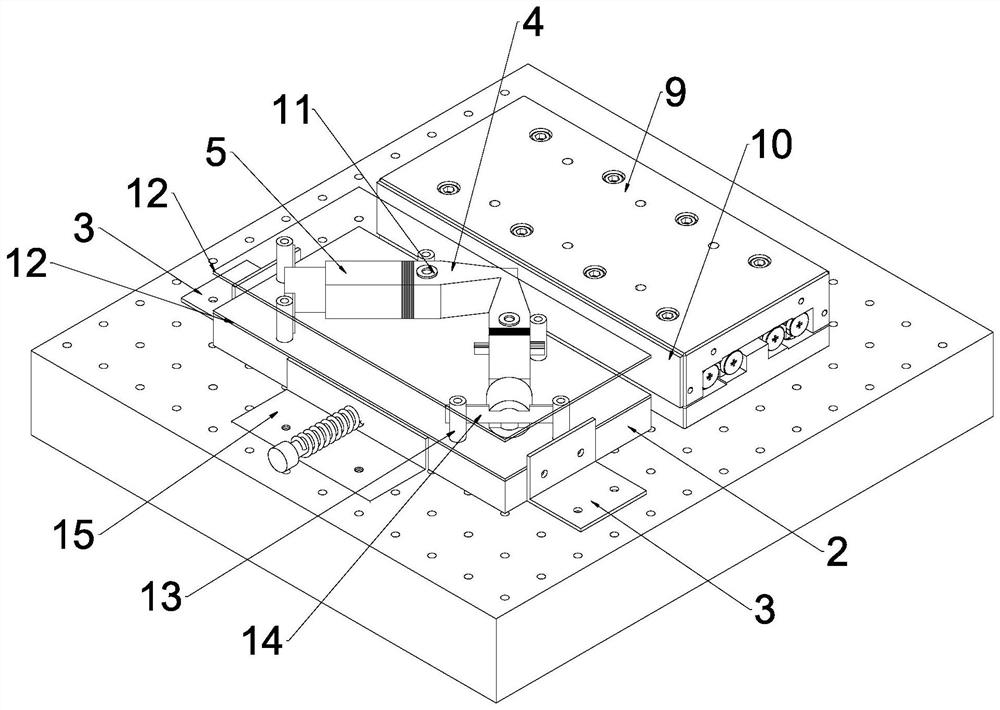

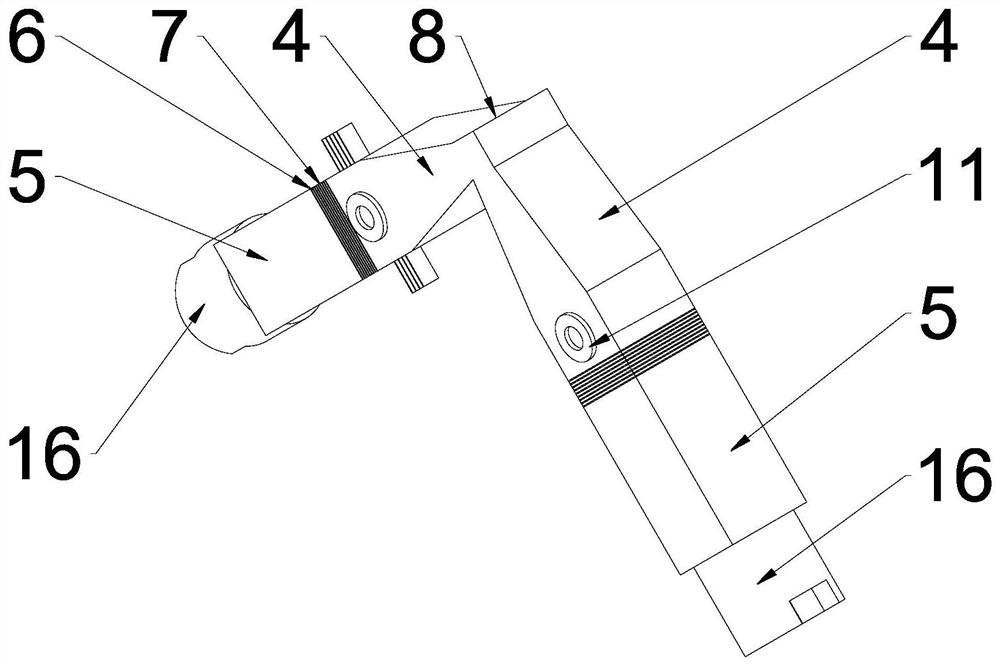

[0032] see Figure 1-Figure 3 , a low-voltage drive V-shaped linear ultrasonic motor of the present invention includes a stator and a mover; the mover includes a slider, the stator includes two Langevin vibrators, and the heads of the two Langevin vibrators are connected As a whole, a V-shaped structure is formed, wherein the outer edges of the heads of the two Langevin oscillators overlap each other, and a driving foot 8 in the shape of a side edge is formed at the front end of the connecting part;

[0033] The ultrasonic motor also includes a limiting structure for preventing the stator from jumping in a direction perpendicular to the movement of the slider, and the limiting structure is arranged on the stator base; wherein, the limiting structure includes a limiting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com