Bearing outer wall machining equipment with feeding and discharging structure

A technology for processing equipment, feeding and discharging materials, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of complex processing structure, troublesome feeding and discharging, and low processing efficiency of milling machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

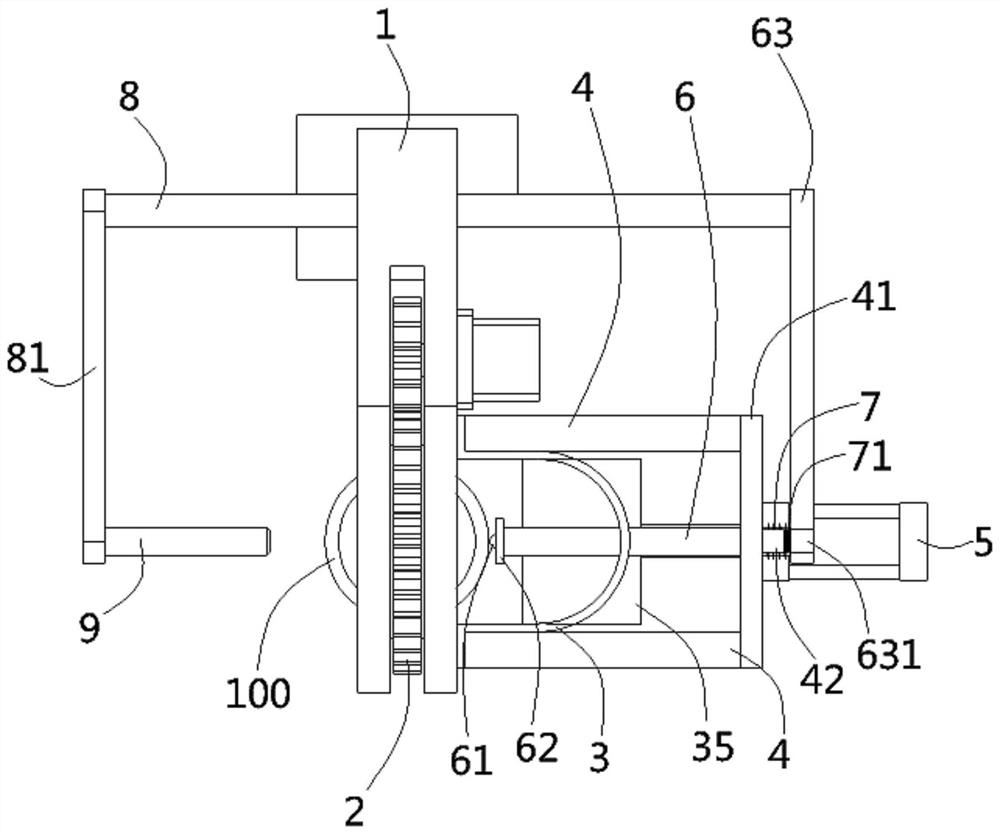

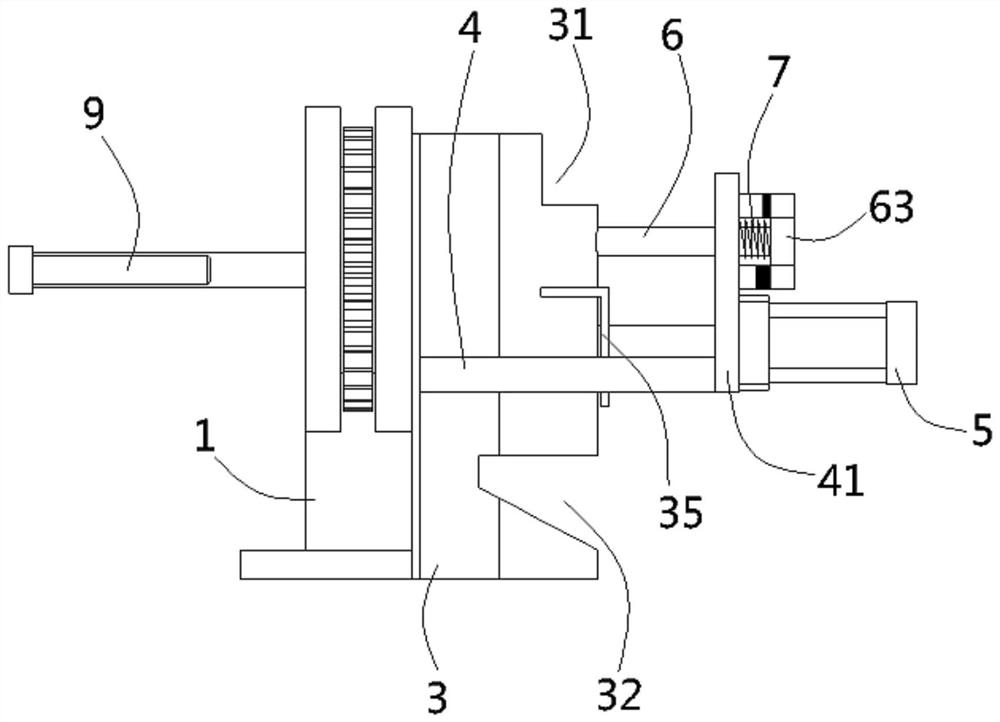

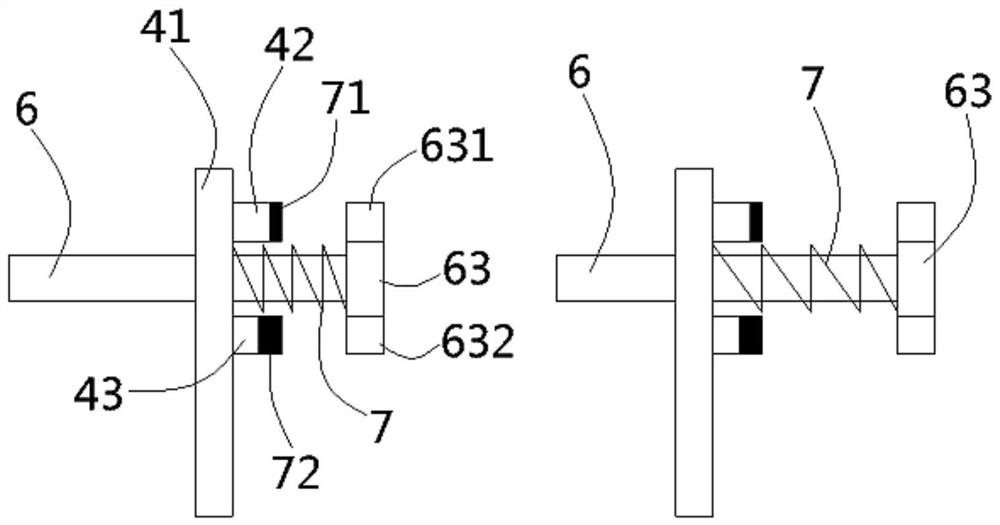

[0022] The following content reference Figure 1 to Figure 4 .

[0023] A kind of bearing outer wall processing equipment with a material inlet and outlet structure according to the present invention includes a headstock 1, a circular rotating seat 2 is provided at the front end of the headstock, and a bearing ring is formed inside the rotating seat. 100 matching positioning slots (not shown), a U-shaped material guide groove 3 is fixed on the headstock side wall on the right side of the swivel seat, the upper end of the material guide groove is formed with a feed port 31, and the lower end is formed with an oblique The discharge opening 32 of setting, the deflector plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com