A test system and test method for testing the performance of digital printing inkjet printing ink

A technology of digital printing and testing system, applied in printing, printing device and other directions, can solve problems such as affecting the use effect of printing system, and achieve the effect of ensuring cleanliness, ensuring accuracy, and accurate and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

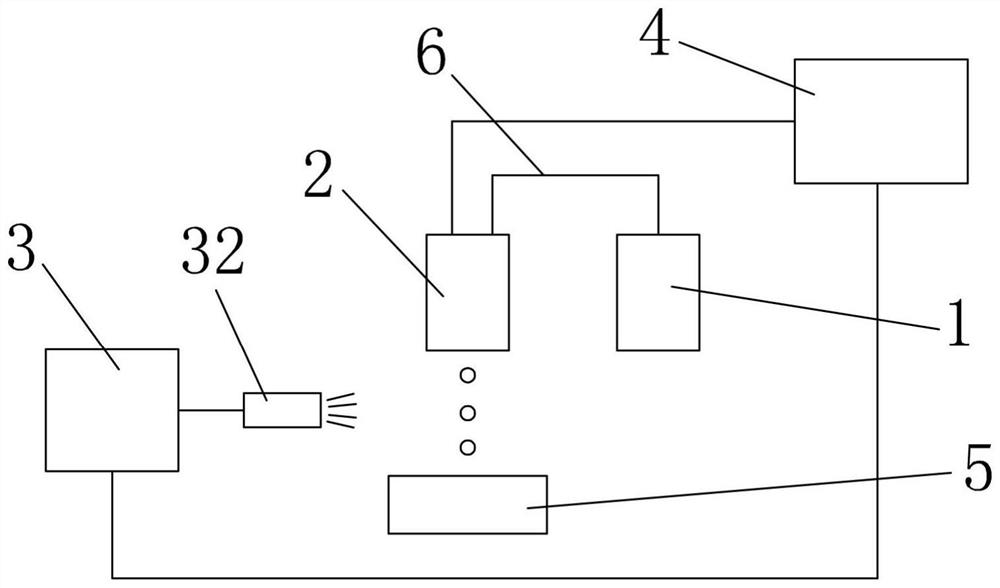

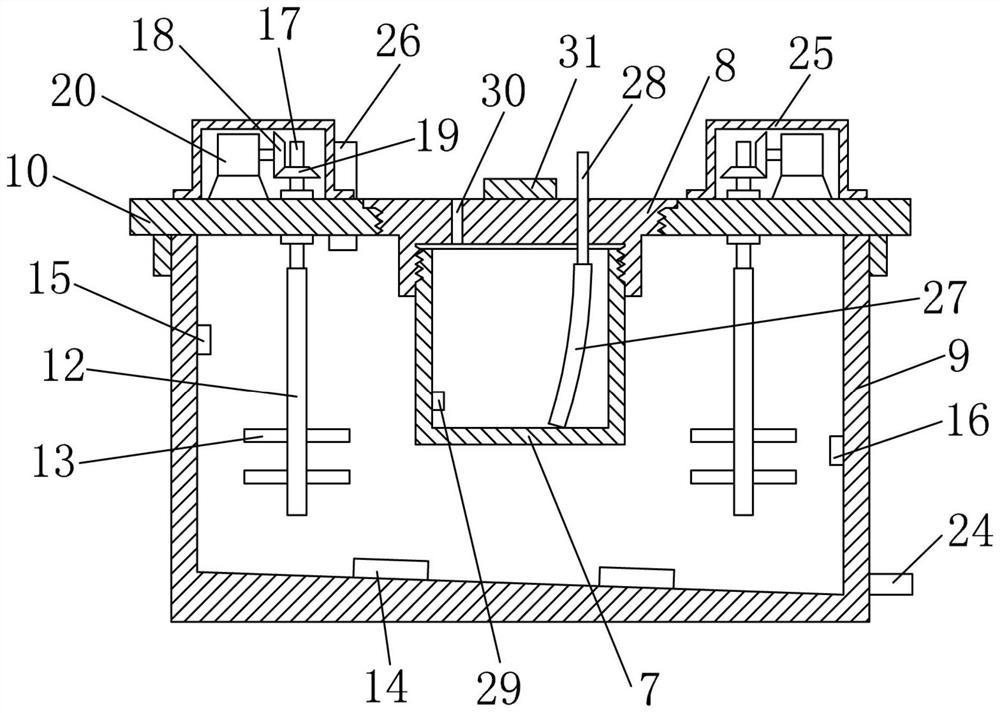

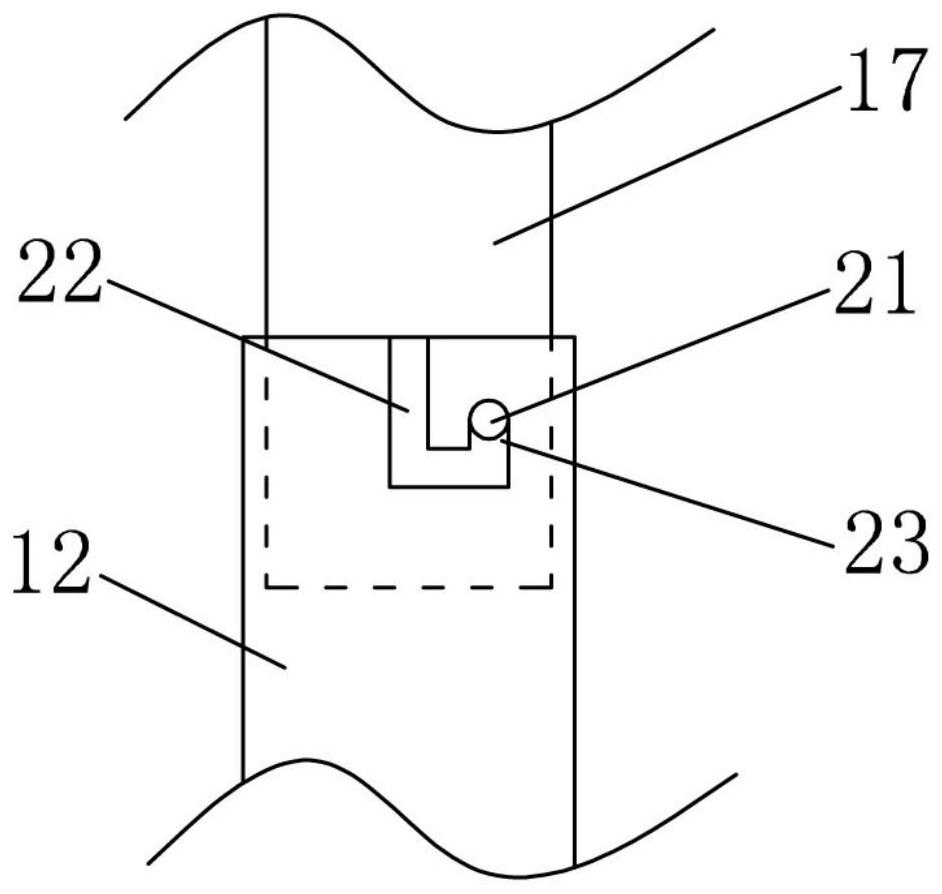

[0036] Embodiment: a kind of test system of testing digital printing jet printing ink performance, as Figure 1-Figure 8 As shown, it includes an ink supply unit 1, a nozzle 2, an ink drop observer 3, a control unit 4, and a droplet suction device 5. The ink supply unit 1 is connected to the nozzle 2 through an ink tube 6 for supplying the nozzle 2. Ink, the nozzle 2 is a piezoelectric nozzle 2, such as the Samba nozzle 2 produced by FUJIFILM, the ink tube 6 is connected with a pump and a valve, and the negative pressure in the ink tube 6 is controlled by the pump and the valve, so that the ink is injected into the nozzle 2; the control unit 4 is electrically connected to the nozzle 2, and is used to control the nozzle 2 to spray ink; the control unit 4 is electrically connected to the ink drop observer 3, and is used to control the ink drop observer 3 to observe and record from the nozzle 2 The shape of the ink droplet ejected, and the recorded information is transmitted to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com