Mixing pile drilling and coring structure and operation process

A technology of drilling coring and operation technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., and can solve problems such as core sample erosion, detection accuracy impact, and core sample integrity, so as to maintain integrity and ensure The effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

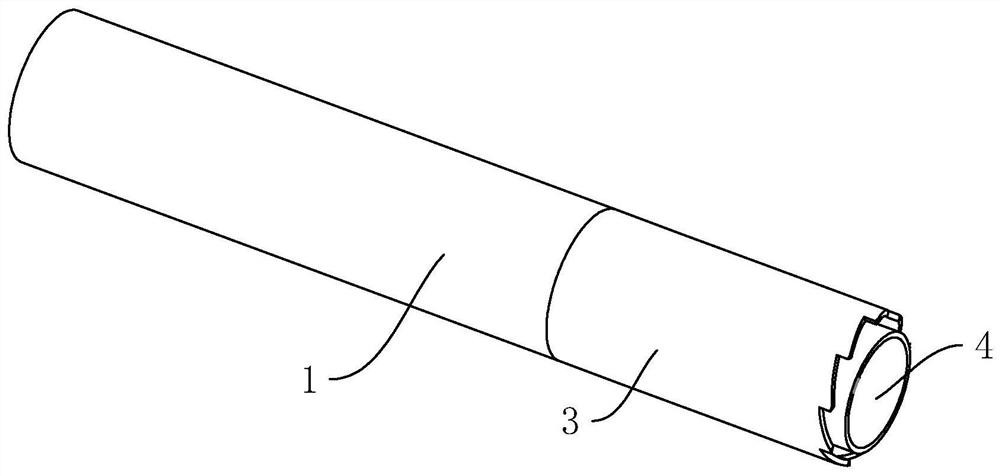

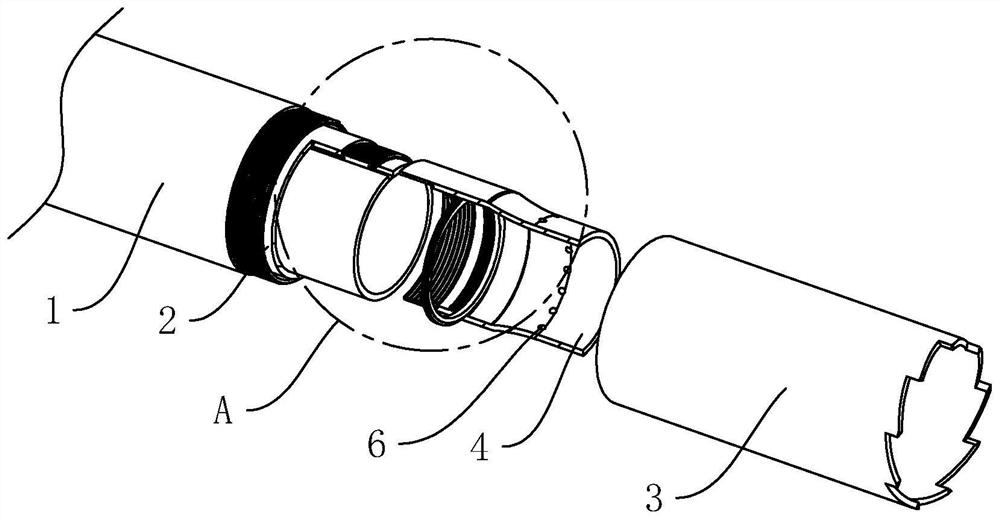

[0047] refer to figure 1 and figure 2 , the stirring pile drilling and coring structure includes a drill pipe body, the drill pipe body includes a cylindrical hollow outer tube 1 and an inner tube 2, wherein the inner tube 2 is located on the inner wall of the outer tube 1 and rotates with the outer tube 1 through a bearing, One end of the outer tube 1 is threaded with a hollow alloy drill bit 3 for drilling the pile body. The diameter of the outer peripheral surface of the alloy drill bit 3 is equal to the diameter of the outer peripheral surface of the outer tube 1 to ensure that the alloy drill bit 3 is installed After the outer tube 1, the flatness between the outer tube 1 and the outer tube 1.

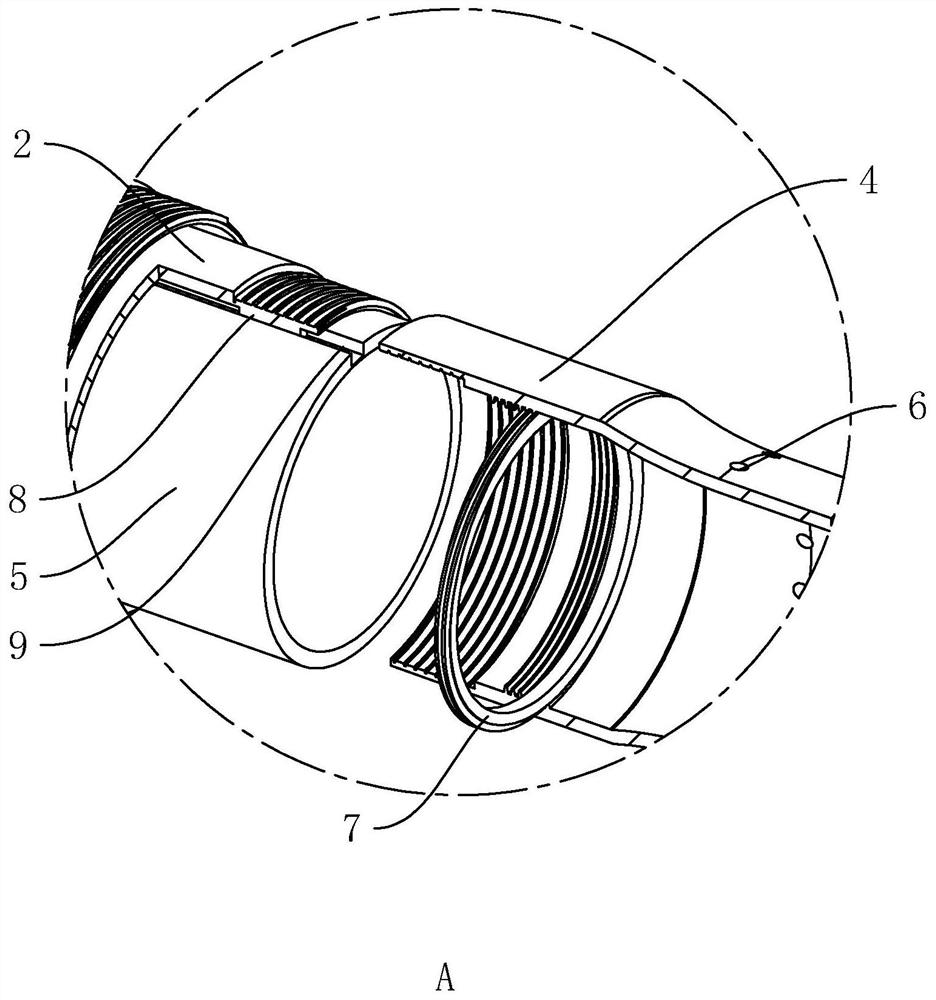

[0048] refer to figure 2 and image 3 The end of the inner tube 2 close to the alloy drill bit 3 is threaded with a hollow guide nozzle 4, the diameter of the end of the guide nozzle 4 close to the inner tube 2 is larger than the diameter of the end of the guide nozzle 4 away...

Embodiment 2

[0053] refer to Figure 4 and Figure 5 The difference between this embodiment and Embodiment 1 is that the guide nozzle 4 is connected and fixed to the inner tube 2 in a different way, wherein the inner tube 2 includes a tube body 201 and a socket fixedly connected to a point in the length direction of the tube body 201 202 , the end surface of the guide nozzle 4 facing the inner tube 2 is provided with an inserting groove 13 , and the inserting portion 202 is inserted and matched with the inserting groove 13 .

[0054] Continue to refer to Figure 4 and Figure 5 The pipe body 201 and the guide nozzle 4 have the same diameter near the free end of the pipe body 201, so as to keep the smoothness between the guide nozzle 4 and the inner pipe 2 after the guide nozzle 4 is installed on the inner pipe 2. Several bolts 10 are arranged on the guide nozzle 4, and the bolts 10 are wound around There are several evenly distributed around the axis of the guide nozzle 4, and the bolts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com