Combination switch for internal combustion engine-driven work machine

A technology of operating machinery and combined switches, which is applied in the direction of machine/engine, mechanical equipment, engine control, etc., can solve the problems of inconvenient maintenance and overhaul, increased damage to parts, and affecting the service life of combined switches, so as to simplify the structure and manufacture The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

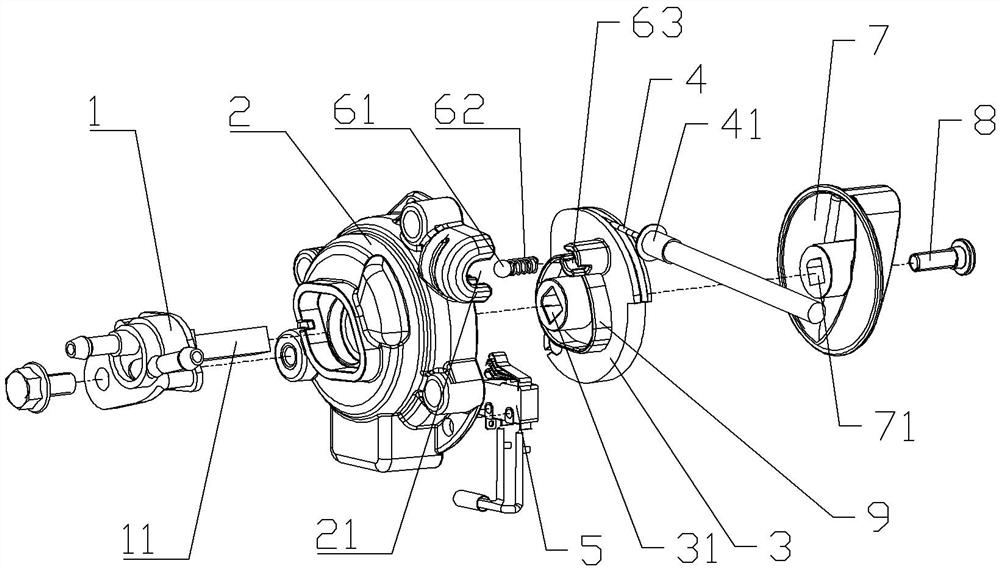

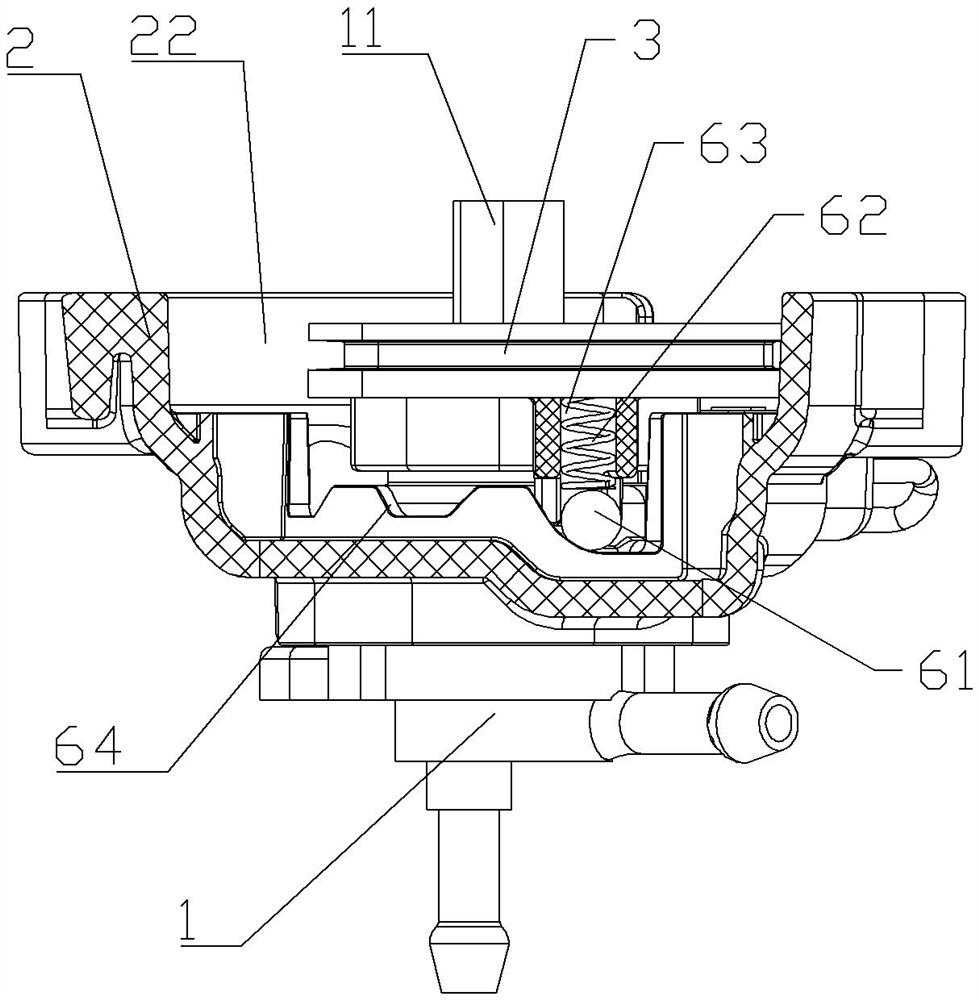

[0025] The reference signs in the drawings of the specification include: fuel switch 1, switch shaft 11, switch seat 2, card slot 21, accommodation chamber 22, cable shaft 3, connection hole 31, cable 4, bushing 41, micro switch 5. Steel ball 61, spring 62, steel ball limit hole 63, gear chute 64, switch handle 7, counterbore 71, screw 8, toggle piece 9.

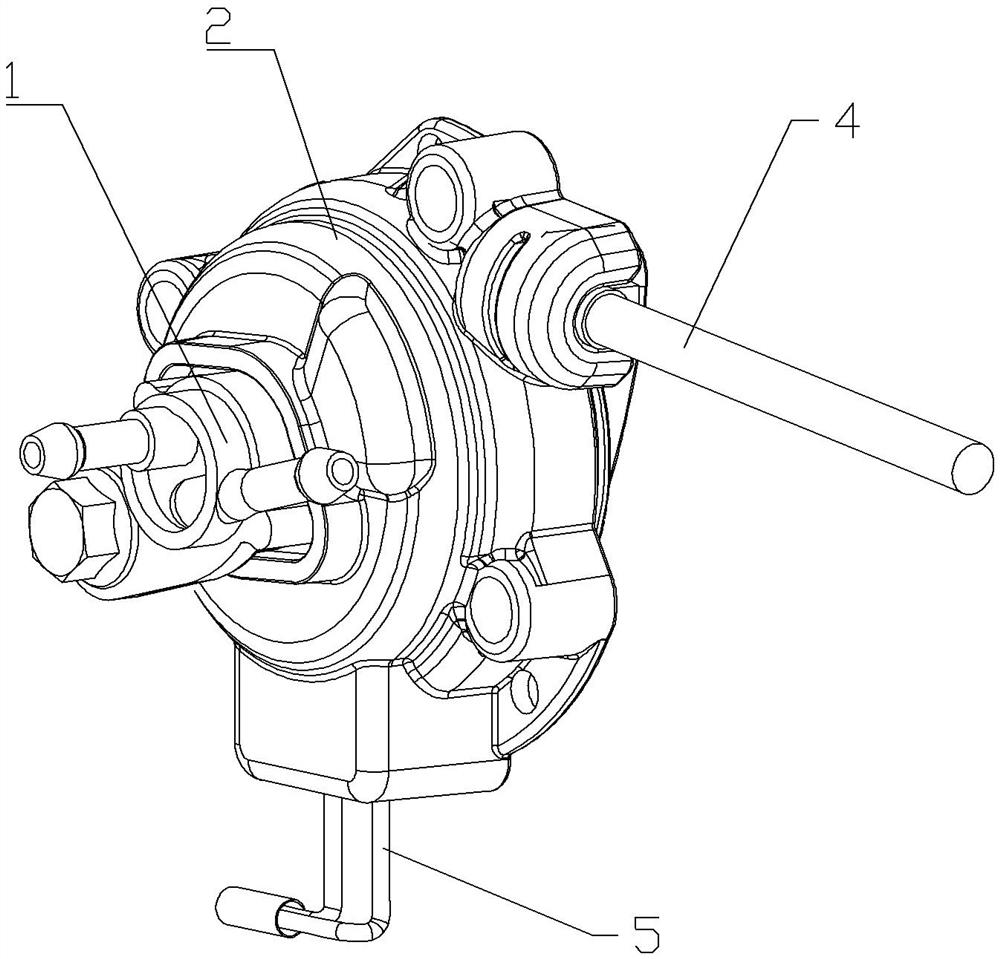

[0026] The embodiment is basically as attached figure 1 , figure 2 , image 3 and Figure 4 Shown: a combination switch for an internal combustion engine-driven operating machine, including a switch base 2, a fuel switch 1, a cable 4, a cable shaft 3, a micro switch 5, a gear structure and a switch handle 7; the switch base 2 has an open The semi-enclosed structure of the mouth-type accommodation chamber 22, the fuel switch 1 is connected to the switch base 2 by bolts, the fuel switch 1 is provided with a switch shaft 11, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com