Rotor assembly of high-power brushless electronic water pump and mounting structure of rotor assembly

An electronic water pump and high-power technology, which is applied in the direction of pump devices, magnetic circuit shape/style/structure, parts of pumping devices for elastic fluids, etc., can solve the problem of small torque and the inability to increase the power of brushless electronic water pumps, etc. problem, to achieve the effect of strong magnetism and low production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below through specific examples.

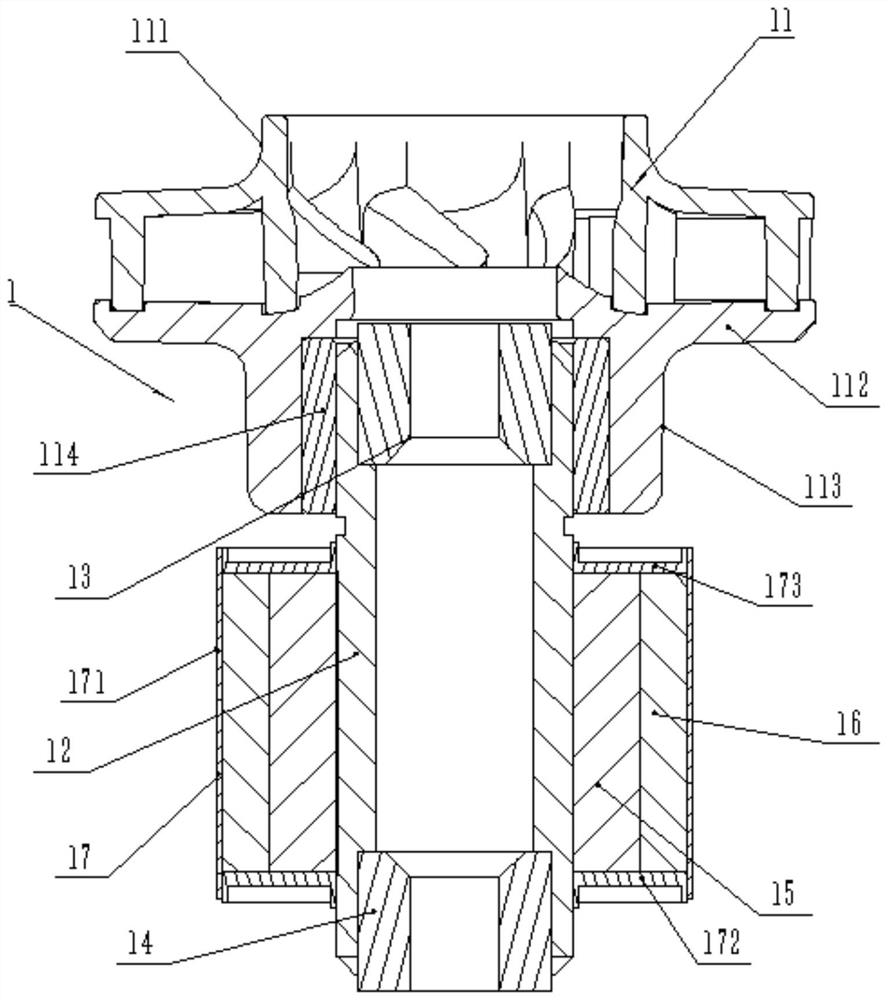

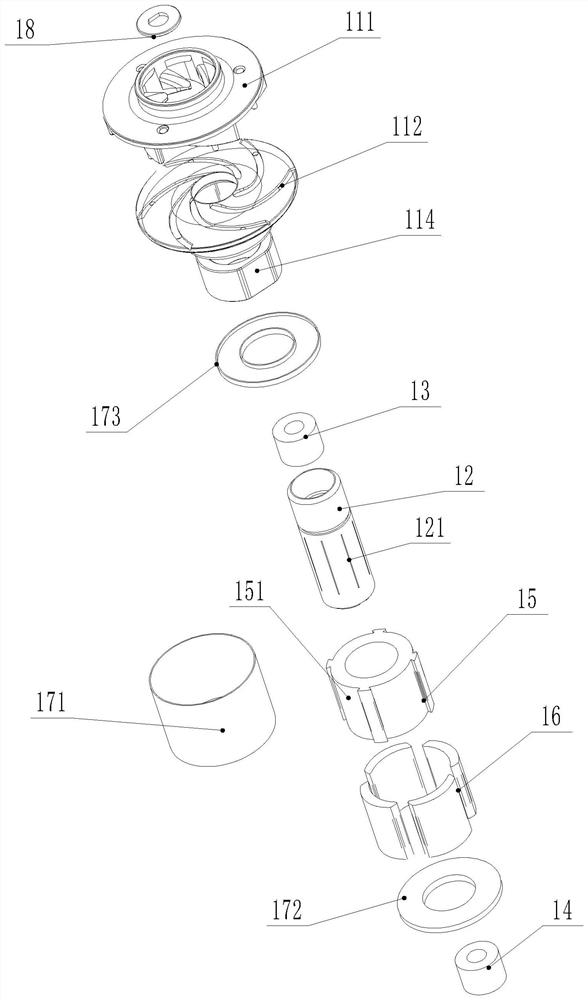

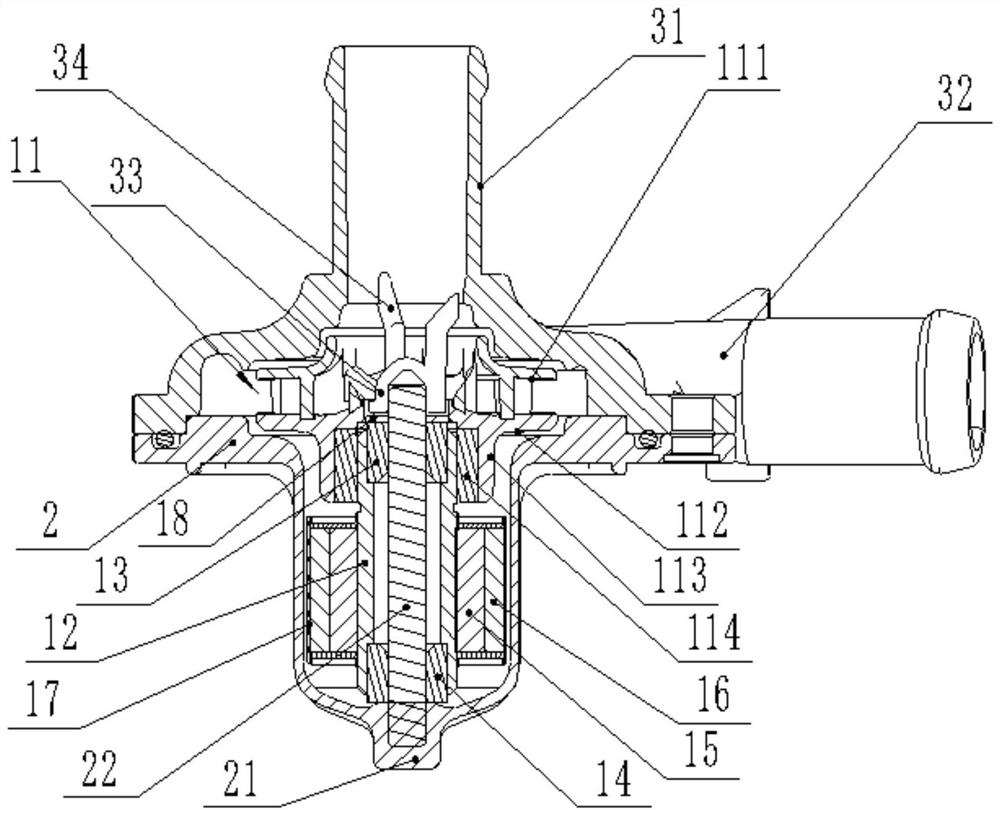

[0030] Such as figure 1 and figure 2As shown, a rotor assembly 1 of a high-power brushless electronic water pump includes an impeller 11 and a rotor sleeve 12, the impeller 11 is fixed on the upper end of the rotor sleeve 12, and the upper and lower ends of the rotor sleeve 12 are An upper wear-resistant lubricating insert 13 and a lower wear-resistant lubricating insert 14 are respectively concentrically embedded in the inner hole, and the upper wear-resistant lubricating insert 13 and the lower wear-resistant lubricating insert 14 are provided with an inner joint with the rotor bushing 12. The center hole of the hole concentric setting, the outer periphery of described rotor bushing 12 is fixed with rotor iron core 15, and the outer circumference of described rotor iron core 15 is evenly distributed with several pieces of sintered RuFeB magnetic steel 16, and described rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com