An automatic defrosting air-temperature vaporizer

An air temperature, vaporizer technology, applied in non-pressure vessels, vessel filling methods, vessel discharge methods, etc., can solve the problems of no defrosting function, increased energy consumption, hidden safety hazards, etc., to improve the vaporization effect, increase the Contact area, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

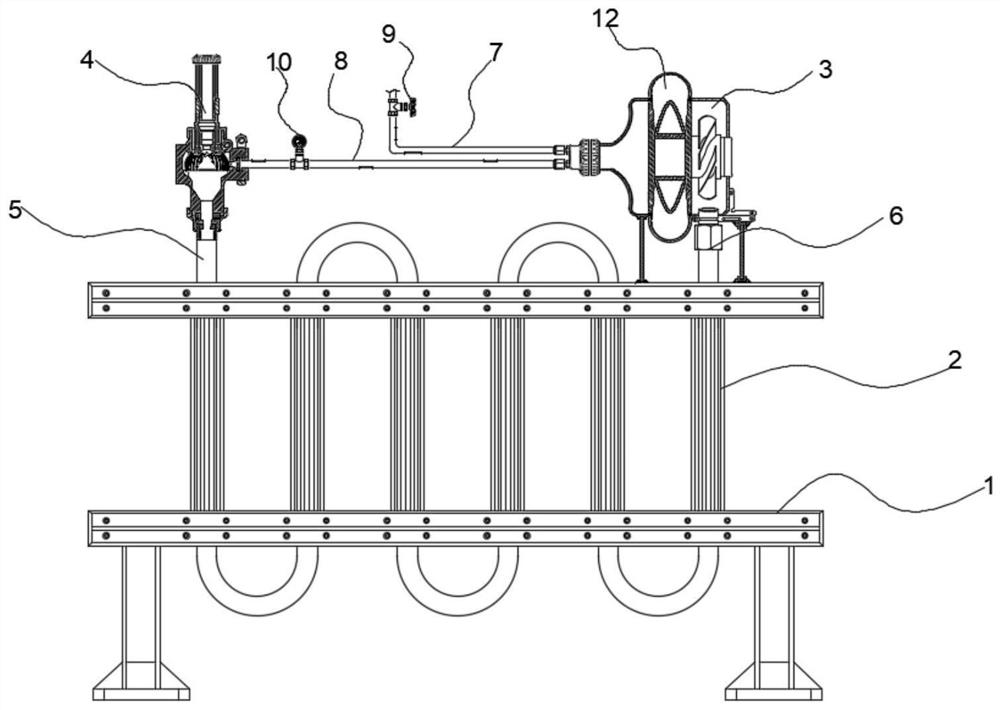

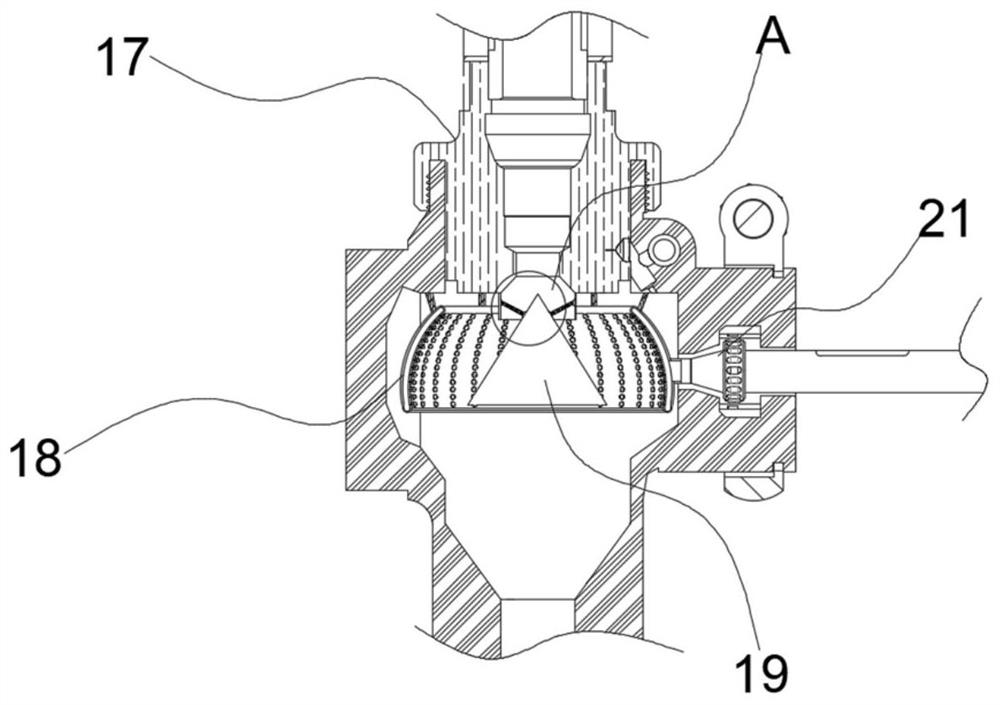

[0037] see figure 1 , in an embodiment of the present invention, an air-temperature evaporator with automatic defrosting, which includes a fixed frame 1, a finned tube set 2, a secondary vaporization pressurization assembly 3, and a liquid inlet defrosting assembly 4, wherein the fixed The frame 1 is used to arrange and fix the finned tube group 2, the left end of the finned tube group 2 is the liquid inlet 5, and the right end is the air outlet 6, and the upper end of the liquid inlet 5 is fixedly installed with a liquid inlet and defrosting assembly 4. In order to initially heat up and vaporize the low-temperature liquid entering the finned tube group 2, wherein the finned tube group 2, the secondary vaporization pressurization component 3 and the liquid inlet defrosting component 4 are all made of aluminum alloy materials, not only High thermal conductivity and light weight make the operation of the whole device more stable;

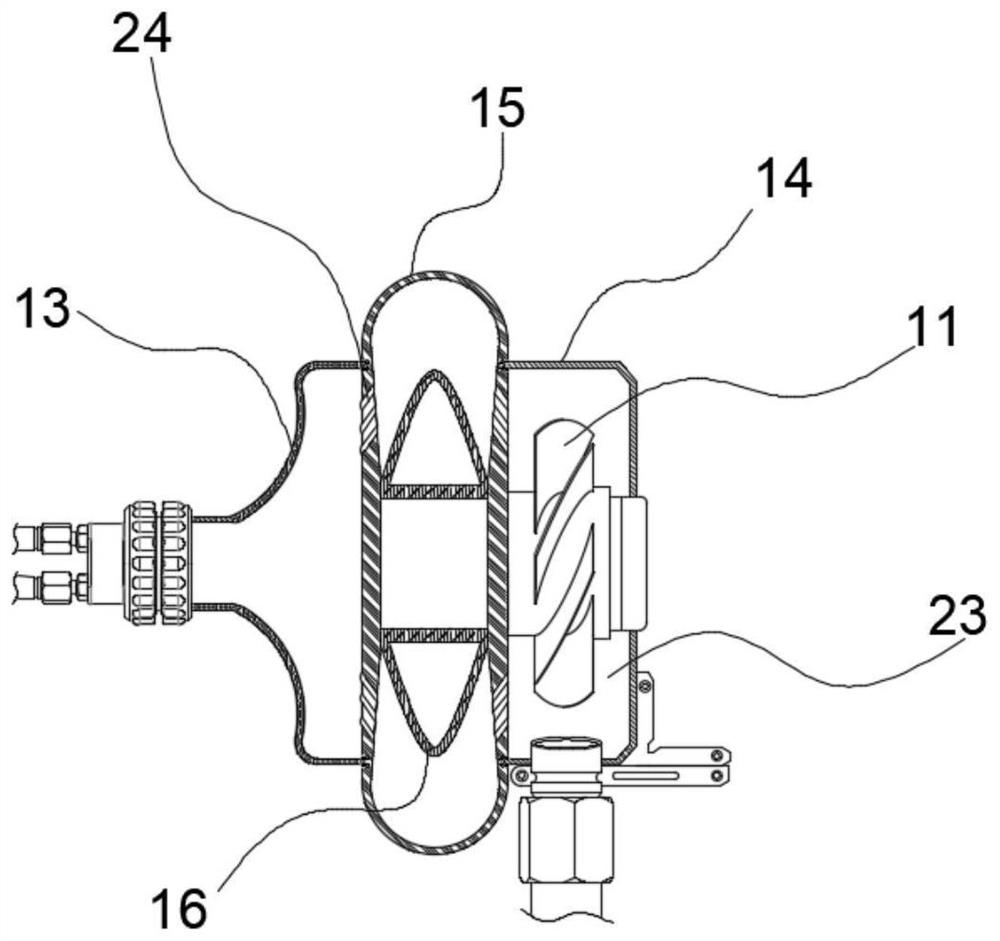

[0038] The secondary vaporization pressurizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com