Heating and winding device for release film

A technology of winding device and release film, used in lighting and heating equipment, winding strips, transportation and packaging, etc., can solve the problems of low energy consumption of heating and dehumidification equipment, reducing heating and cooling efficiency, and energy consumption, etc. Achieve the effect of improving energy utilization rate, outstanding energy saving effect and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

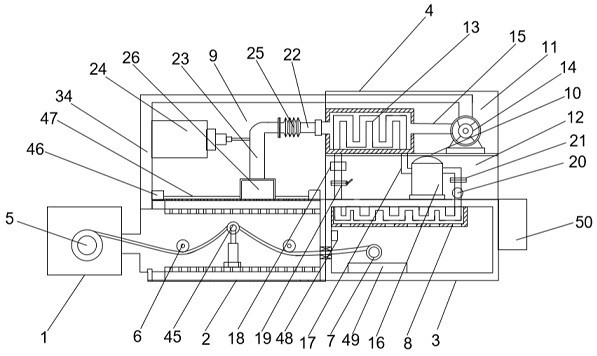

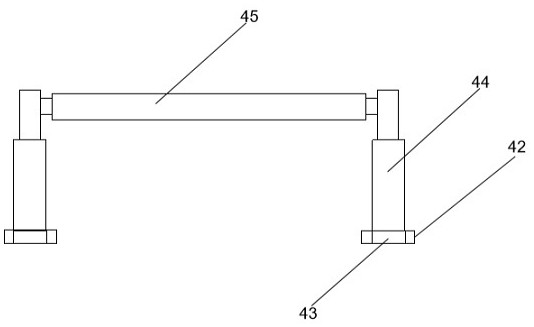

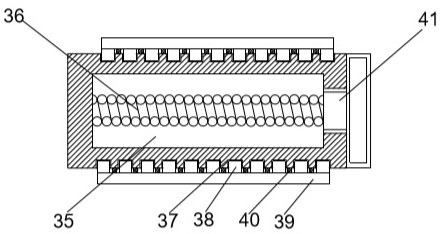

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0023] see Figure 1-4 , a heating and winding device for a release film, comprising a winding box 1, a heating box 2, a winding box 3 and a cooling and heat exchange box 4; a winding roller 5 is installed in the winding box 1, and the winding roller 5 is Wrapped with a release film, one end of the heating box 2 is connected to the unwinding box 1, and the other end is connected to the winding box 3. The heating box 2 is provided with a guide roller 6, and the top of the heating box 2 is connected to a hot air inlet device 9. A winding roller 7 is installed in the coil box 3, and the release film enters the guide roller 6 in the heating box 2 after being unrolled from the output roller 5. There are two guide rollers 6 installed on both sides of the heating box 2 , after passi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com