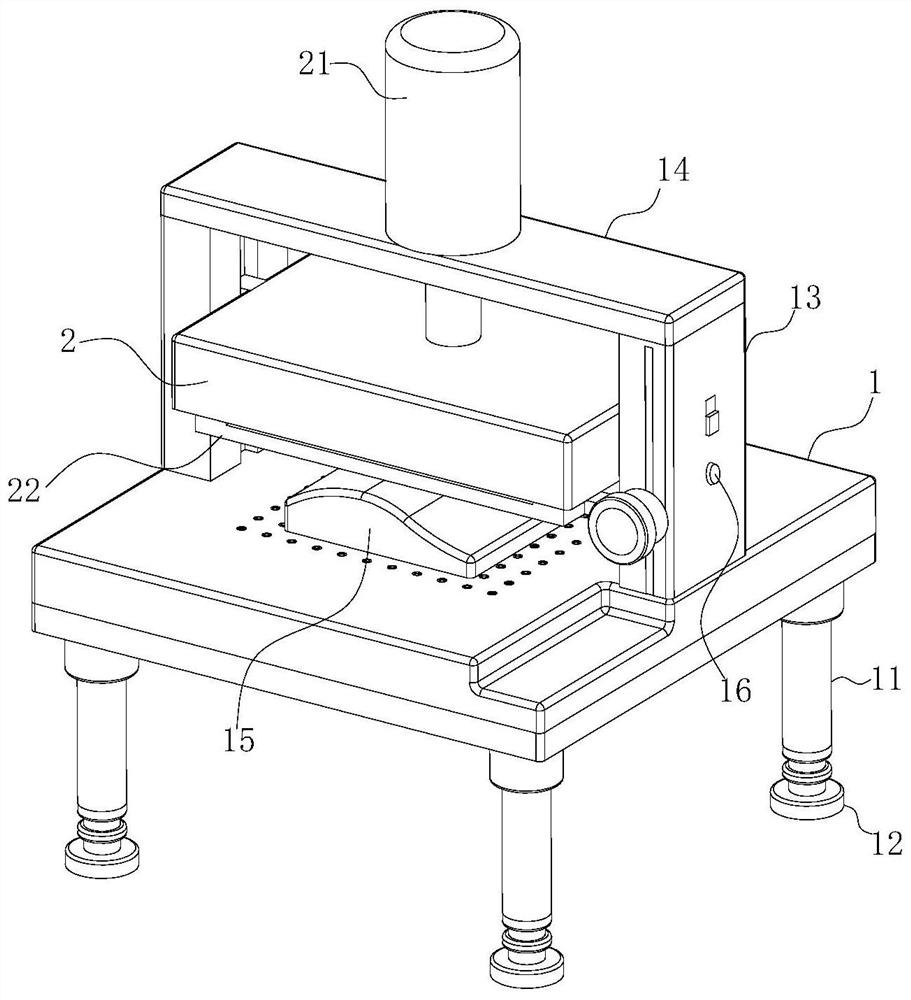

Measuring device for industrial design

A measuring device, industrial design technology, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of high professional requirements, high cost, low detection accuracy, etc., to reduce professional requirements, meet use requirements, The effect of improved data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

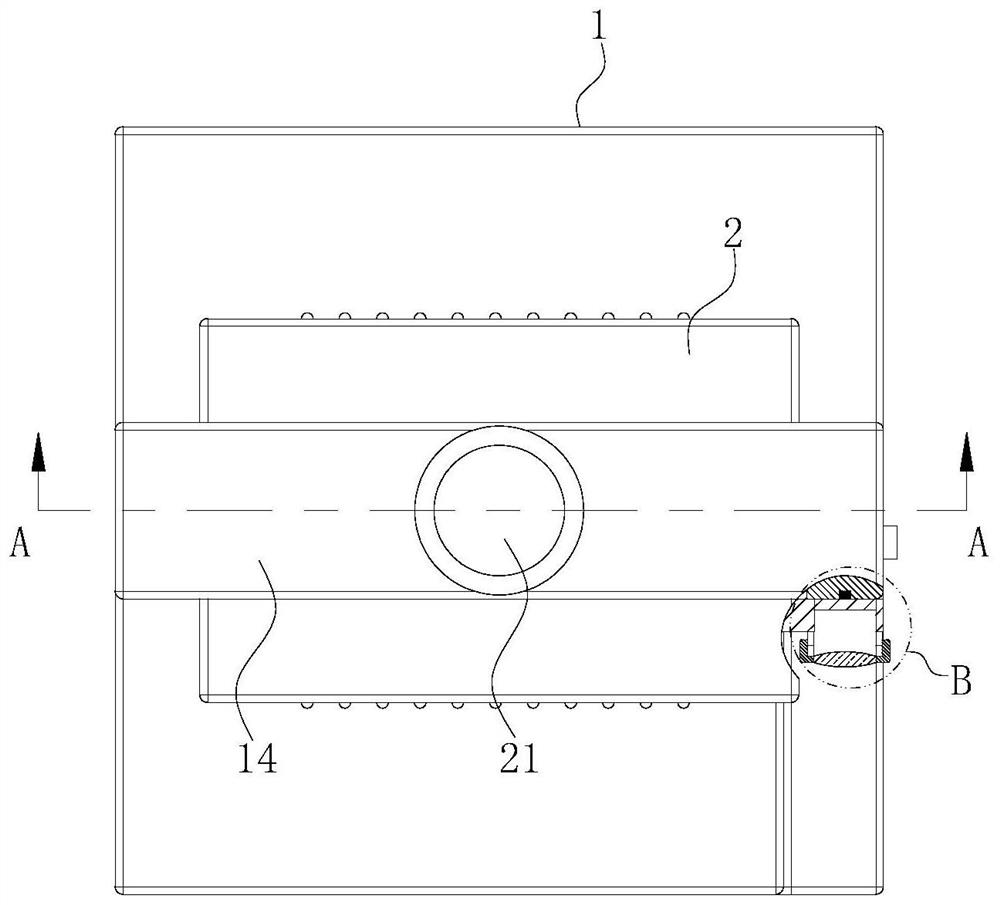

Method used

Image

Examples

Embodiment approach

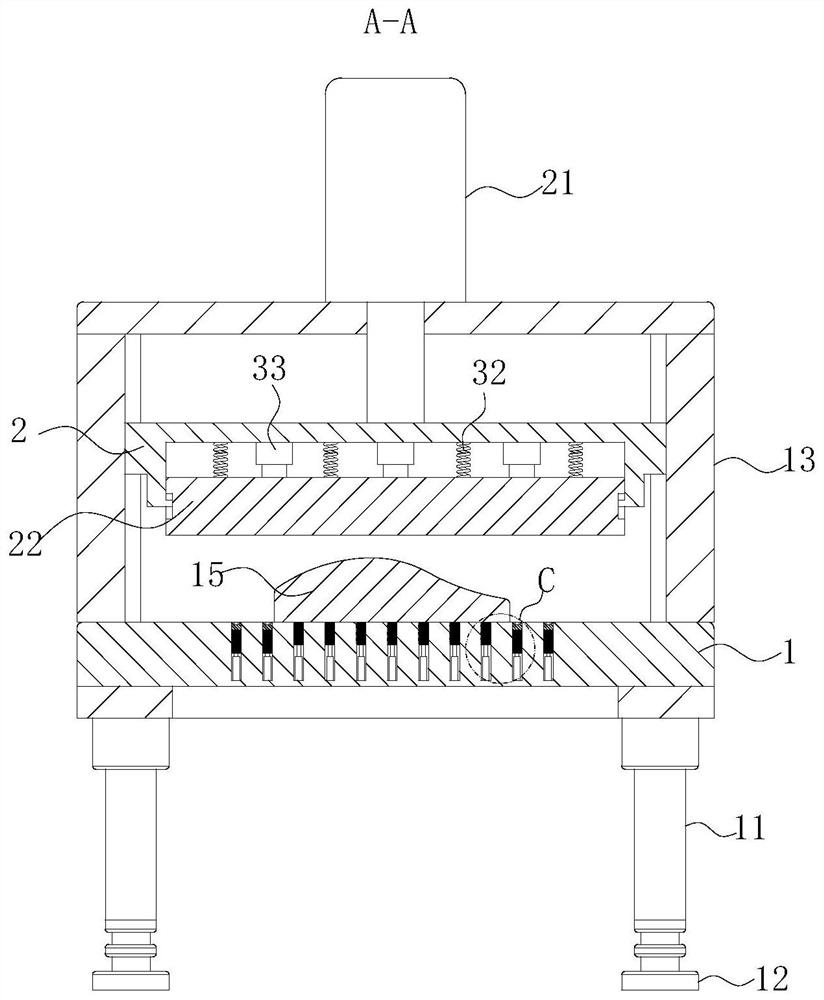

[0032] As an embodiment of the present invention, the lower surface of the moving plate 2 is provided with an adjustment groove, and the light pressing plate 22 is slid up and down connected to the inside of the adjustment groove; the groove bottom of the adjustment groove is fixed with uniformly arranged springs 32, and the springs 32 are fixedly connected between the upper surface of the light pressing plate 22;

[0033] When working, the light pressure plate 22 is connected to the adjustment groove of the moving plate 2 by sliding up and down. When the light pressure plate 22 moves downward and squeezes to the measuring top block 3, the light pressure plate 22 will move upward inside the adjustment groove , by adjusting the spring 32 inside the groove to realize the motion buffering and reset work of the light pressing plate 22 .

[0034] As an embodiment of the present invention, the groove bottom of the adjustment groove is fixedly connected with third cylinder rods 33 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com