a burning ring

A combustion ring and annular chamber technology, applied in the field of combustion rings, can solve the problems of corrosion of the combustion ring, inability to effectively protect the combustion ring, etc., and achieve the effect of saving production cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

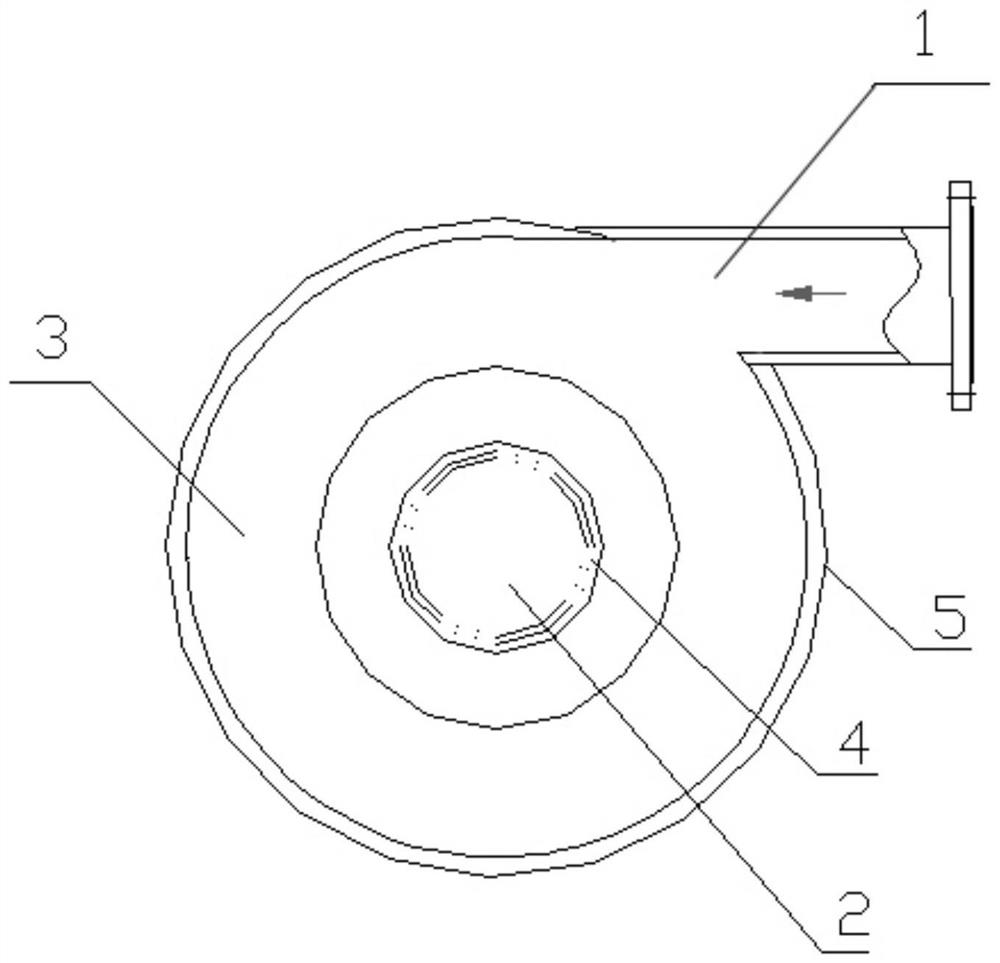

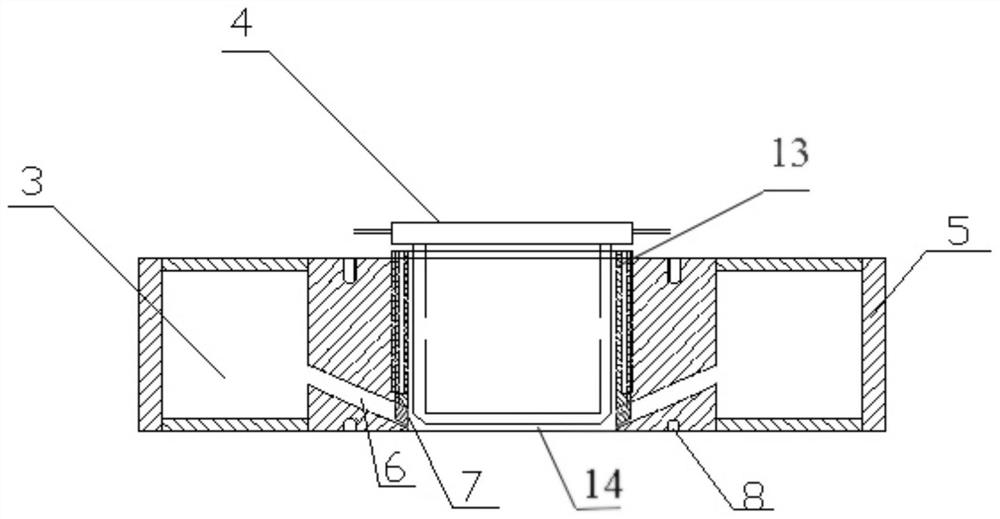

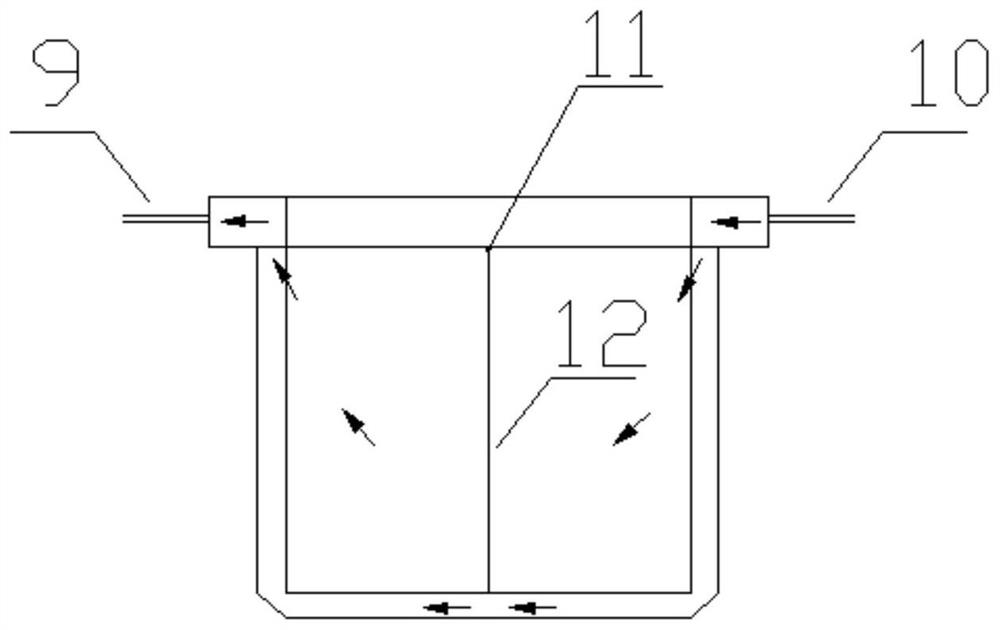

[0024] The present invention discloses a combustion ring, such as Figures 1 to 2 Shown, comprising a volute 5 having a radial via 13, titanium tetrachloride gas channel and oxygen channel 2, the surface of the radial via 13 is provided with a jacket 4 for accommodating the cooling medium, and the end of the jacket 4 is not extended to the end of the radial via 13, i.e., the end of the jacket is still a certain distance from the end of the radial via;

[0025] There is a toroidal chamber 3 in the volute 5, a first channel 1 between the annular chamber 3 and the outer wall of the volute 5, and a second channel 6 between the end of the radial via;

[0026]The first channel 1, the annular chamber 3 and the second channel 6 form a titanium tetrachloride gas channel for titanium tetrachloride gas inflow, radial through-hole center to form an oxygen channel for oxygen inflow 2, titanium tetrachloride gas, oxygen flow to the end of the radial via, so the radial via end forms a mixed react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com