Special clamp and method for machining NDT sample

A special fixture and processing method technology, applied in the direction of manufacturing tools, electric processing equipment, metal processing equipment, etc., can solve the problems of high cost, difficult processing of NDT samples, and long time, so as to save research and development, promote and apply value, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

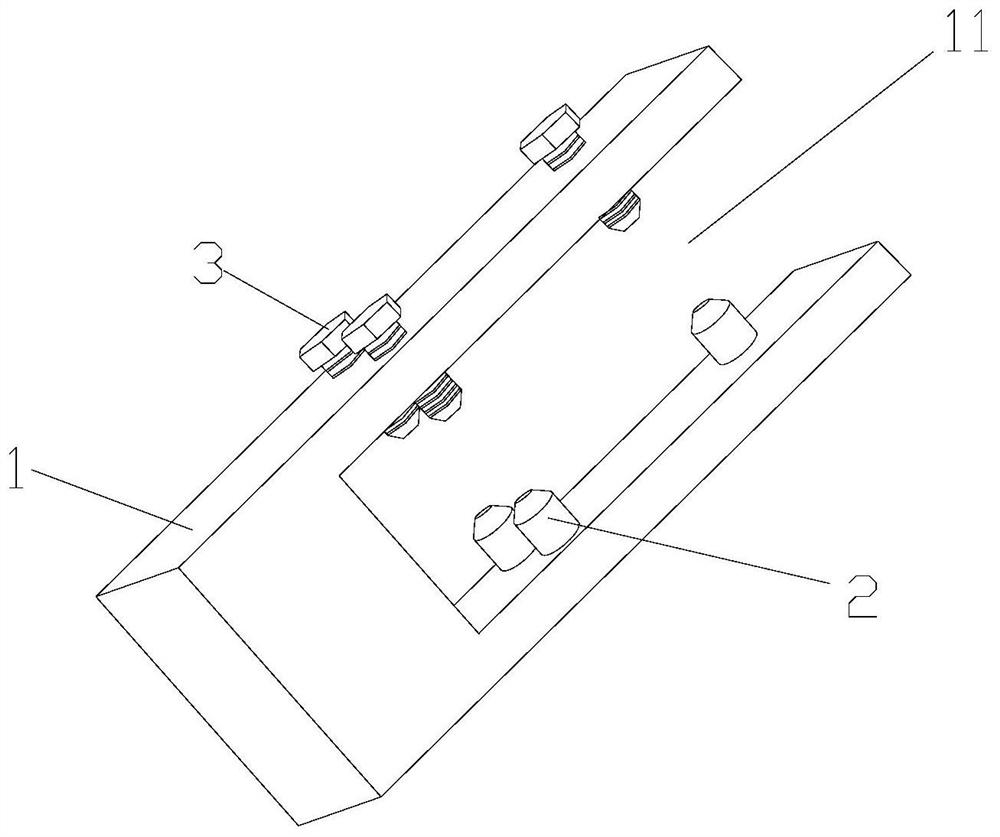

[0026]Such asfigure 1 ,2A special fixture for NDT sample processing is shown, including a fixture 1 with a clamping bayonet 11, one side of the clamping bayonet 11 is provided with a plane positioning point, the plane positioning point includes three plane positioning Cylinder 2, the other side of the clamping bayonet 11 is provided with a corresponding lock column 3; one side of the clamp 1 is close to the working platform of the wire-controlled cutting machine tool so that the plane determined by the three plane positioning columns 2 is vertical It is used on the working platform of CNC wire cutting machine tool.

[0027]According to the geometric theorem of three points to determine a plane, use three small cylinders to weld and fix the clamping bayonet 11 on one plane, and then install three bolts on the other plane to form three plane positioning cylinders to ensure three small The cylinder and the three bolts are basically on the same axis. Finally, each surface of the fixture an...

Embodiment 2

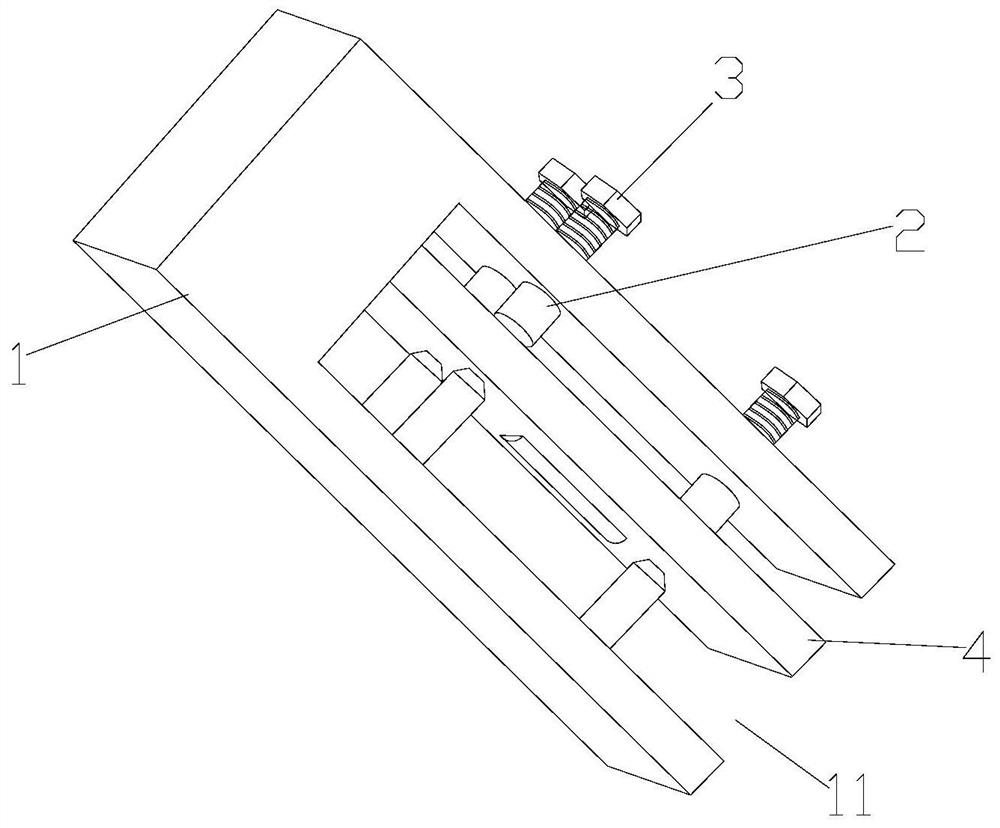

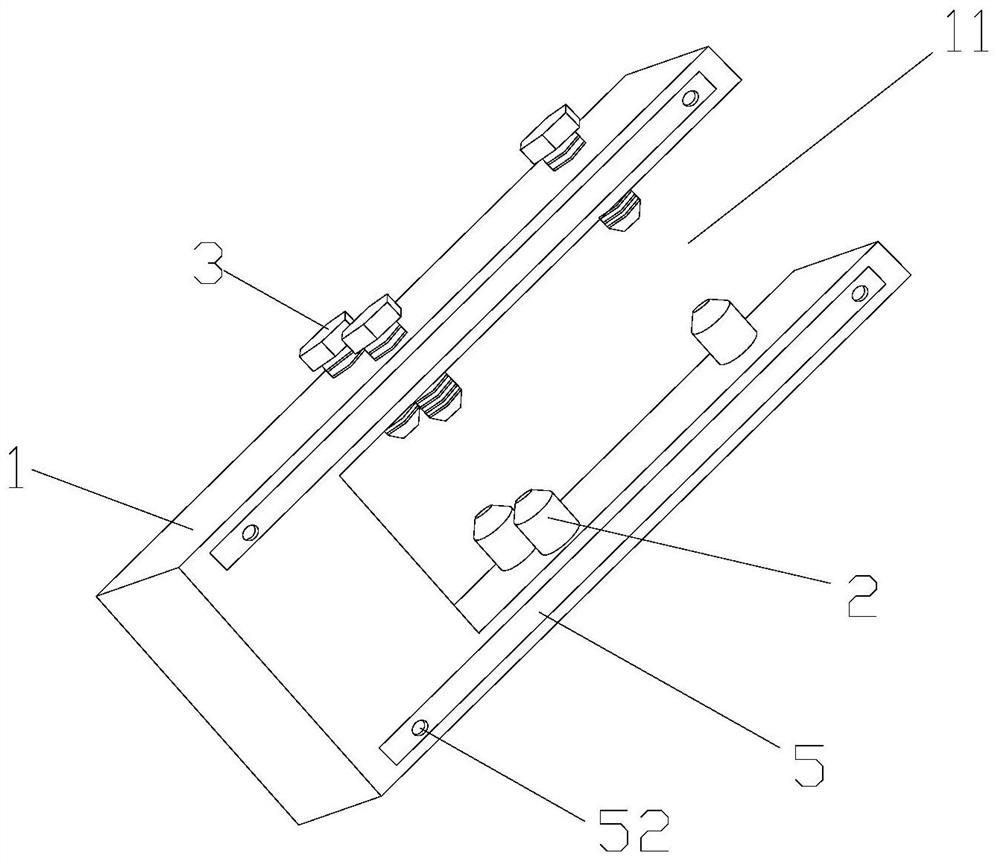

[0034]Such asimage 3 ,4A special fixture for NDT sample processing is shown, including a fixture 1 with a clamping bayonet 11, one side of the clamping bayonet 11 is provided with a plane positioning point, and the plane positioning point includes at least three planes Positioning column 2, the other side of the clamping bayonet 11 is provided with a corresponding lock column 3; one side of the clamp 1 is close to the working platform of the wire-controlled cutting machine tool, so that the three planes are positioned on the plane determined by the column 2 The working platform is perpendicular to the CNC wire cutting machine tool.

[0035]In this embodiment, the plane positioning point is composed of three plane positioning cylinders 2. If there are samples in special circumstances, four or more plane positioning cylinders 2 can be used.

[0036]The lock column 3 is a bolt, and the bolt is screwed to one side of the clamping bayonet 11, and the NDT sample 4 is fixed by tightening the bol...

Embodiment 3

[0044]The present invention provides a NDT sample processing method, which includes the following steps: 1) Fix the special fixture for NDT sample processing on the CNC wire cutting work platform; 2) Check the plane determined by the three fixed plane positioning cylinders and the CNC wire cutting The verticality of the working platform of the machine tool; 3) Correct the verticality of the plane determined by the three fixed plane positioning cylinders and the working platform of the CNC wire-cutting machine tool; 4) Install the NDT sample in the clamping port of the fixture, and lock the bolt Fix it; 5) Call the processing program for processing; 6) Detect each processing size; 7) Adjust and modify the processing program, and finally process a shape. Its clamping is convenient, and the work efficiency is greatly improved; using the NDT special fixture, each NDT sample only needs to be processed once, which improves the processing efficiency and reduces the processing cost; avoids ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com