A multi-degree-of-freedom fast clamping adjustment device for efficient machining of plane-symmetric shells

An adjustment device and surface symmetry technology, which is applied in the direction of positioning devices, metal processing equipment, metal processing machinery parts, etc., to achieve the effect of easy fine-tuning and alignment, and easy turning and clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and embodiments.

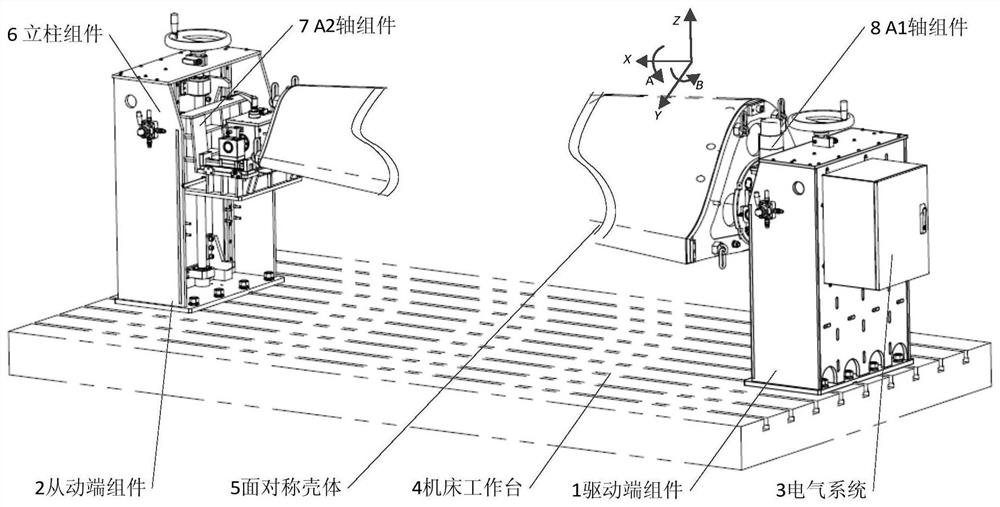

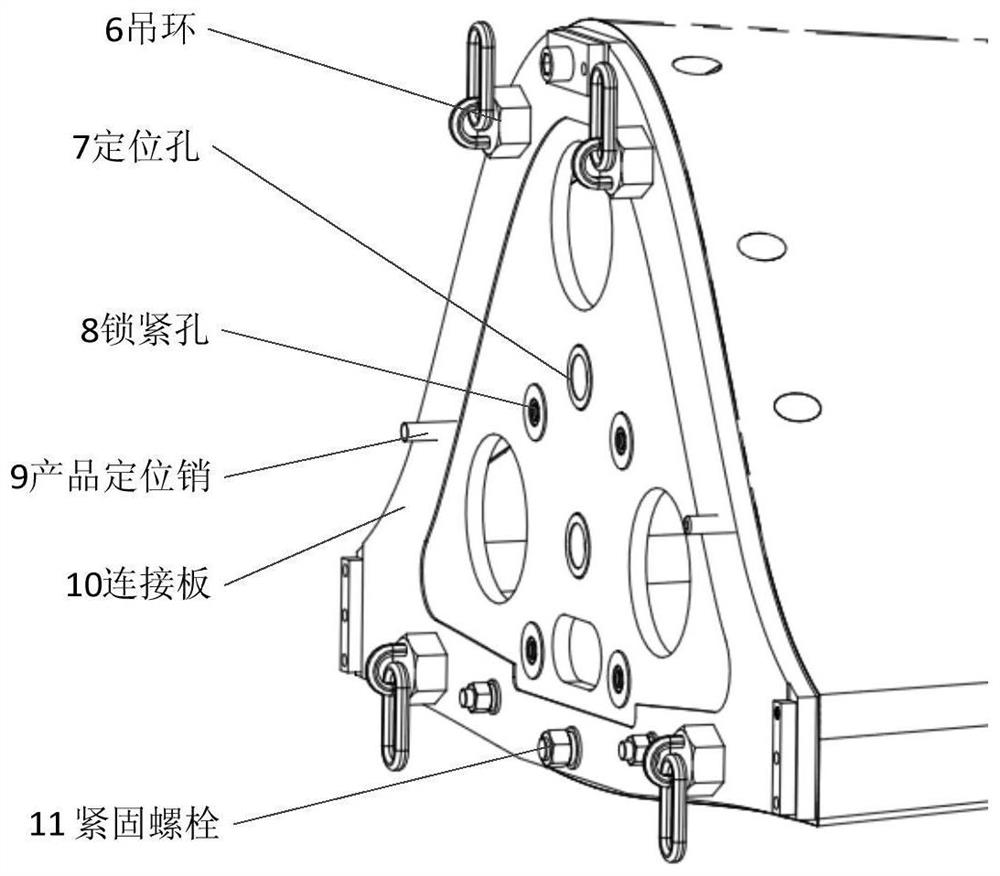

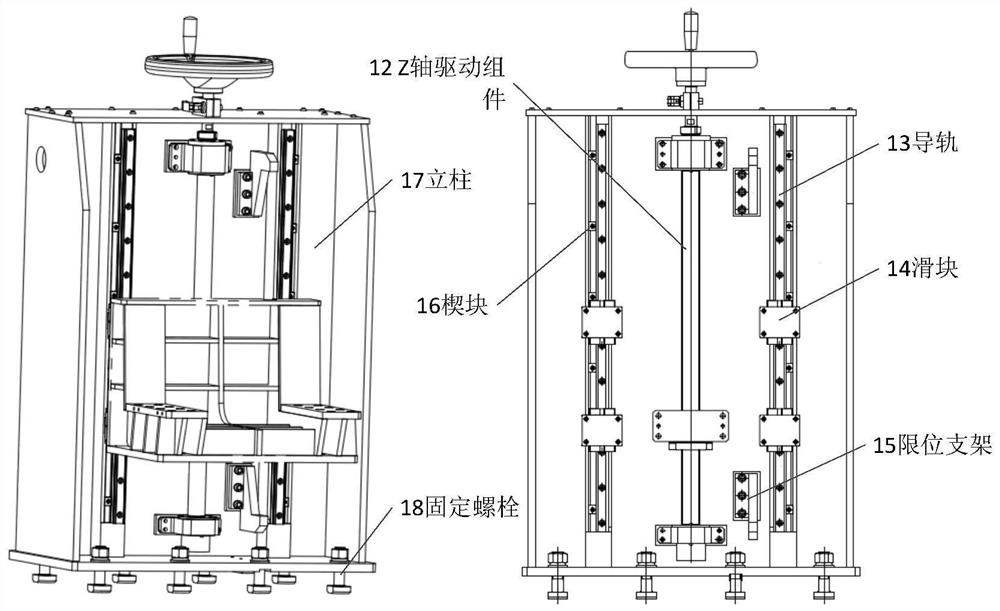

[0026] like figure 1 Shown is a multi-degree-of-freedom fast clamping adjustment device for a symmetrical shell with special-shaped planes. The rapid clamping adjustment device includes two parts: an electric circuit system and a mechanical system: the circuit system is the circuit control for realizing the entire flipping action; the mechanical system It includes a drive end assembly 1, a driven end assembly 2, and an electrical system 3. The drive end assembly 1 and the driven end assembly 2 are installed and fixed on the machine tool table 4 through T-bolts 9, and the plane symmetric housing 5 is connected to the drive end assembly 1 and the driven end assembly 2 through the large and small end faces respectively, so as to realize clamping , and is driven by the A1 axis component 8 and the A2 axis component 7 to realize the movement adjustment of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com