Automatic polishing device for cold-rolled steel in high-end equipment manufacturing

A polishing device and cold-rolled steel technology, which is applied to grinding drive devices, manufacturing tools, grinding/polishing equipment, etc., can solve problems such as inability to polish cold-rolled steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

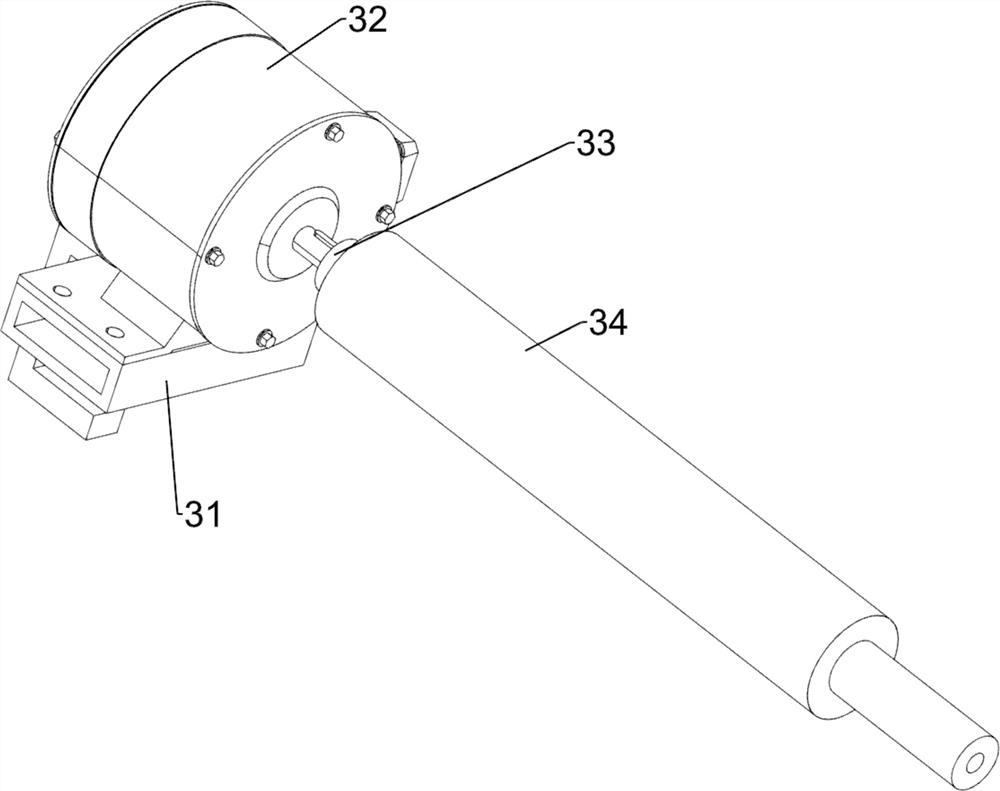

[0029] An automatic polishing device for cold-rolled steel in high-end equipment manufacturing, such as Figure 1-4 As shown, it includes a frame 1, a placement assembly 2, a grinding assembly 3 and a pushing assembly 4. The left side of the frame 1 is provided with the placement assembly 2, the right side of the frame 1 is provided with the grinding assembly 3, and the upper middle of the frame 1 is provided with There is push component 4.

[0030] When it is necessary to polish the cold-rolled steel, first place the cold-rolled steel on the placing component 2, and adjust the height of the cold-rolled steel by placing the component 2, and then control the grinding component 3 to start working, and then the worker can manually pass through The pushing component 4 pushes the cold-rolled steel to the right, so that the grinding component 3 grinds the cold-rolled steel. When one side of the cold-rolled steel is polished, the cold-rolled steel can be turned over, and then the pus...

Embodiment 2

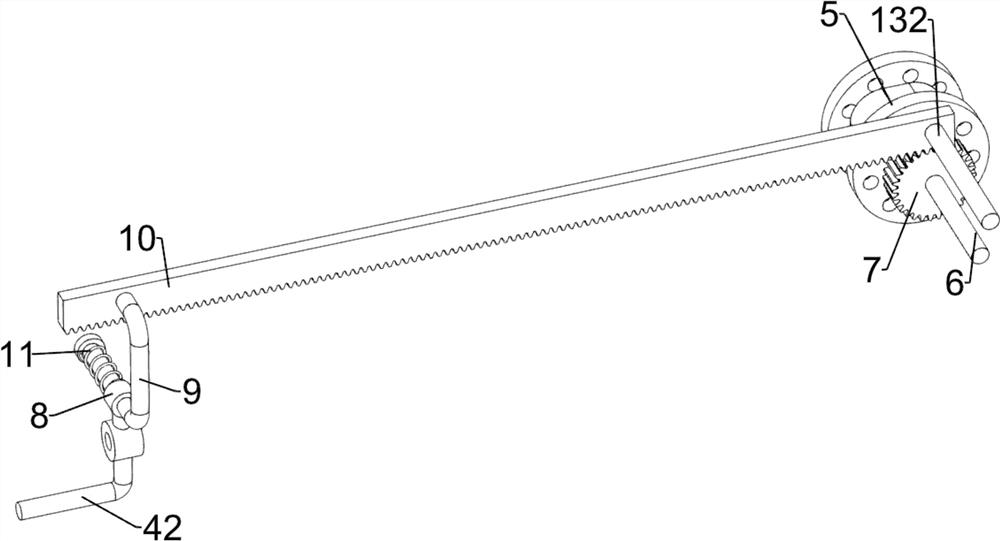

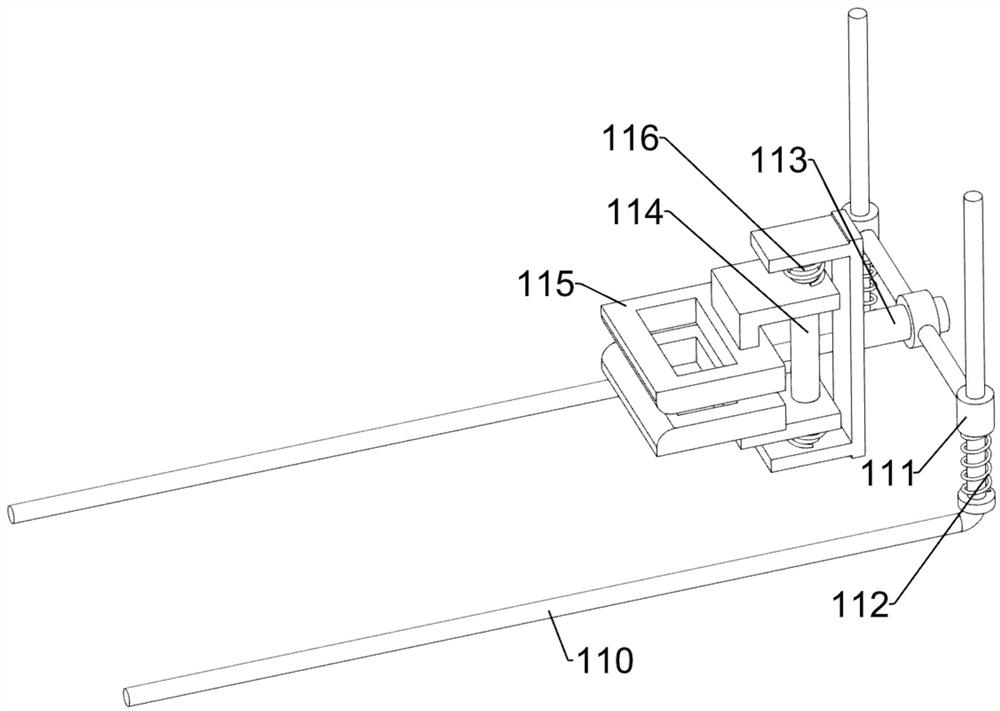

[0038] On the basis of Example 1, such as Figure 4-9 As shown, it also includes a planetary reducer 5, a second rotating shaft 6, a first gear 7, a sliding sleeve 8, a second connecting frame 9, a first rack 10, a second spring 11, a first special-shaped frame 101, a second Fixed frame 12, hollow block 13, first wedge block 14 and the 3rd spring 15, first rotating shaft 33 front sides are provided with planetary reducer 5, planetary reducer 5 front sides are provided with second rotating shaft 6, on the second rotating shaft 6 The key is connected with the first gear 7, the first connecting frame 42 top is connected with the sliding sleeve 8, the sliding type is provided with the second connecting frame 9 on the sliding sleeve 8, the second connecting frame 9 top is connected with the first rack 10, the first The rack 10 meshes with the first gear 7, the second spring 11 is connected between the second connecting frame 9 and the sliding sleeve 8, the front side of the left pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com