Cutting device with dust collection structure for PVC plate processing

A board processing and cutting device technology, which is applied in the field of board processing, can solve the problems of a large amount of dust, wood chips, flying wood chips, and poor dust collection effect, and achieve the effect of convenient use, simple operation, and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

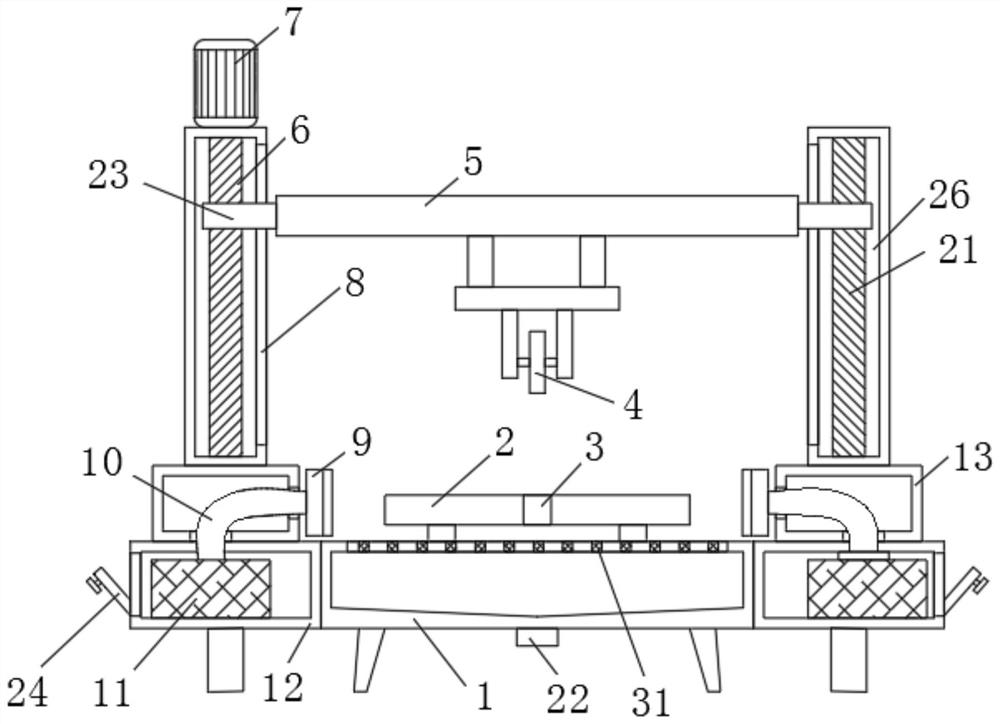

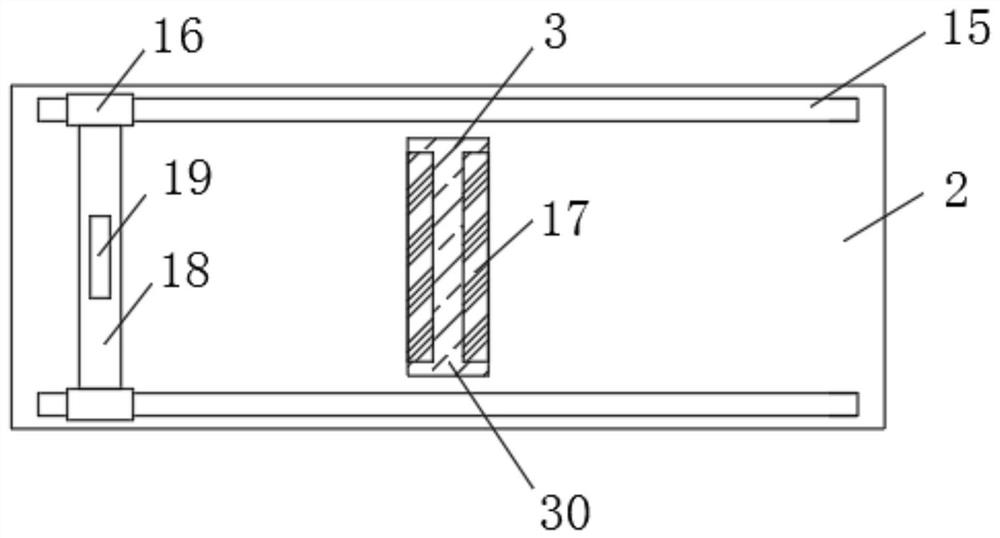

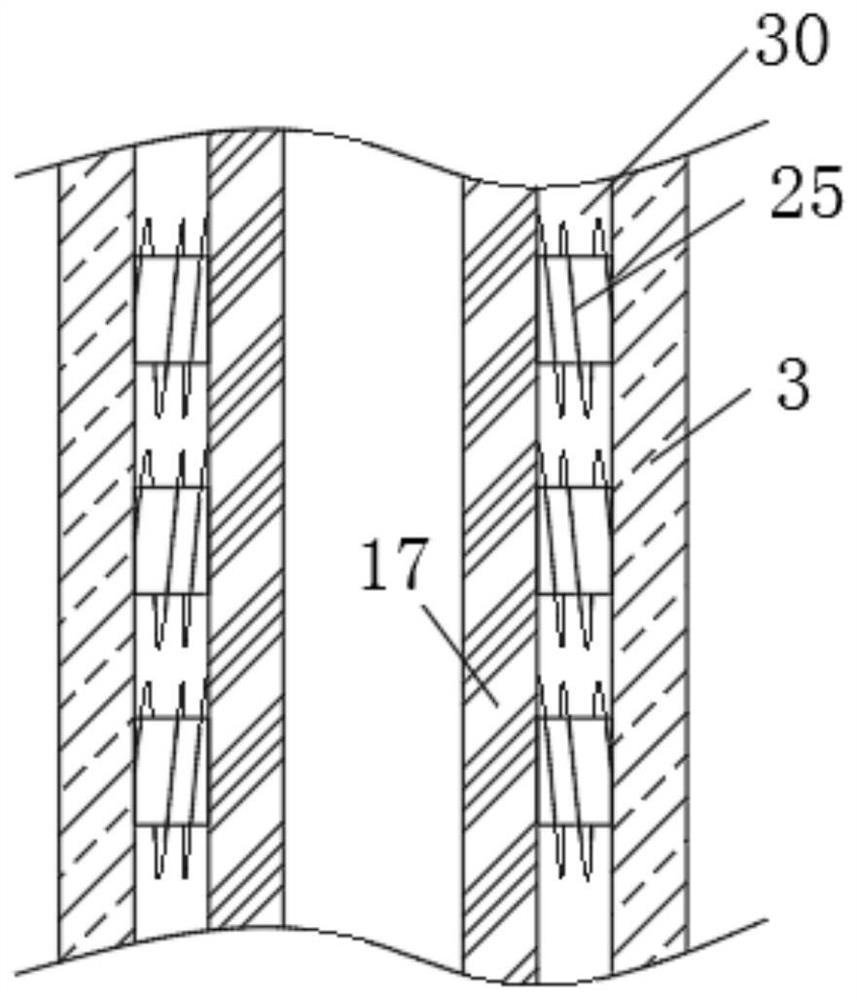

[0028] Example: such as Figure 1-5 As shown, a cutting device with a dust suction structure for PVC sheet processing in the present invention includes a workbench 1, a plurality of through holes 31 are dug on the top surface of the workbench 1, and a cutting plate 2 is provided on the top of the workbench 1. , the cutting board 2 and the workbench 1 are fixedly connected by a connecting piece, two sliding mechanisms 29 are symmetrically arranged on the cutting board 2, a cutting groove 3 is cut on the top surface of the cutting board 2, and a limiting groove 3 is arranged inside the cutting board 2. position mechanism 30, both ends of the workbench 1 are fixedly connected with fixed bins 12, and one end of the fixed bins 12 away from the workbench 1 is rotatably connected with a movable door 24, and the interior of the fixed bins 12 is provided with a filter mechanism 28, two by two The top surface of the fixed warehouse 12 is fixedly connected with a support seat 13, and a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com