Unmanned aerial vehicle with telescopic vehicle arms

A technology of unmanned aerial vehicle and telescopic machine, applied in the field of unmanned aerial vehicles, can solve the problems of large space occupied, inconvenient transportation of unmanned aerial vehicles, inability to extend and retract the arms, etc., and achieves a convenient adjustment process, avoids shaking, and is not easily deformed and damaged. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

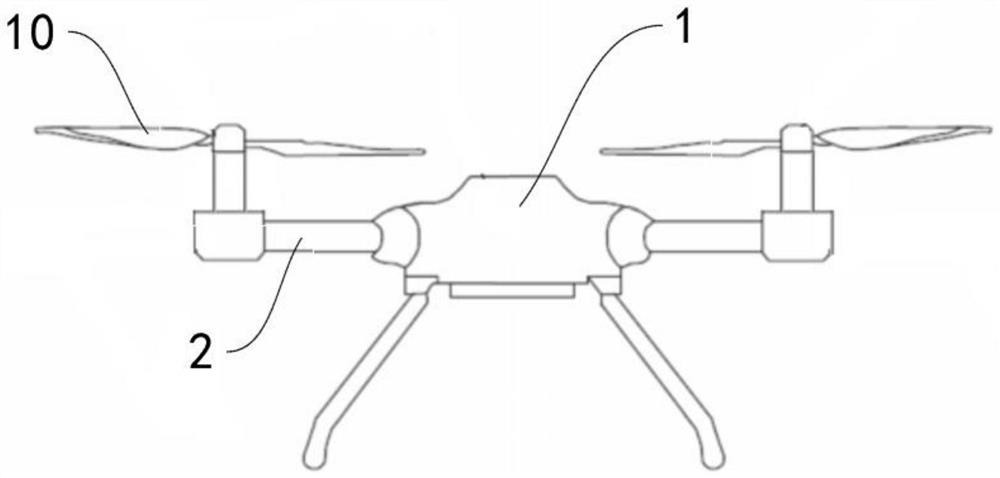

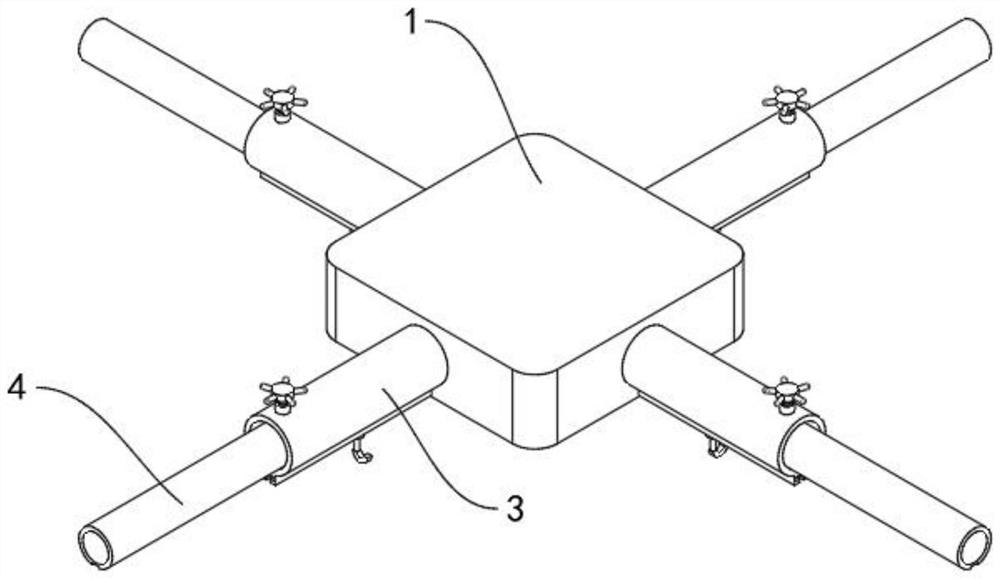

[0033] Refer to the accompanying drawings below Figure 1-Figure 5 Describe the UAV with telescopic arm 2 according to Embodiment 1 of the present invention, the device includes a fuselage 1, an arm 2 and a rotor assembly 10, wherein the arm 2 includes a first arm 3 and a second arm 4 .

[0034] The first arm 3 is a hollow pipe with both ends open. One end of the first arm 3 is connected to the fuselage 1. The first arm 3 is provided with a fastening shaft that can move back and forth along the radial direction of the first arm 3. 5, and the end of the fastening shaft 5 close to the central axis of the first arm 3 is provided with a flexible pad 6, and the inner peripheral wall of the first arm 3 is provided with a limiting protrusion 7.

[0035] Specifically, refer to figure 2 , image 3 and Figure 4 , taking one of the machine arms 2 as an example, the first arm 3 is a long tube extending in the left and right direction, the first arm 3 is hollow and open at both ends,...

Embodiment 2

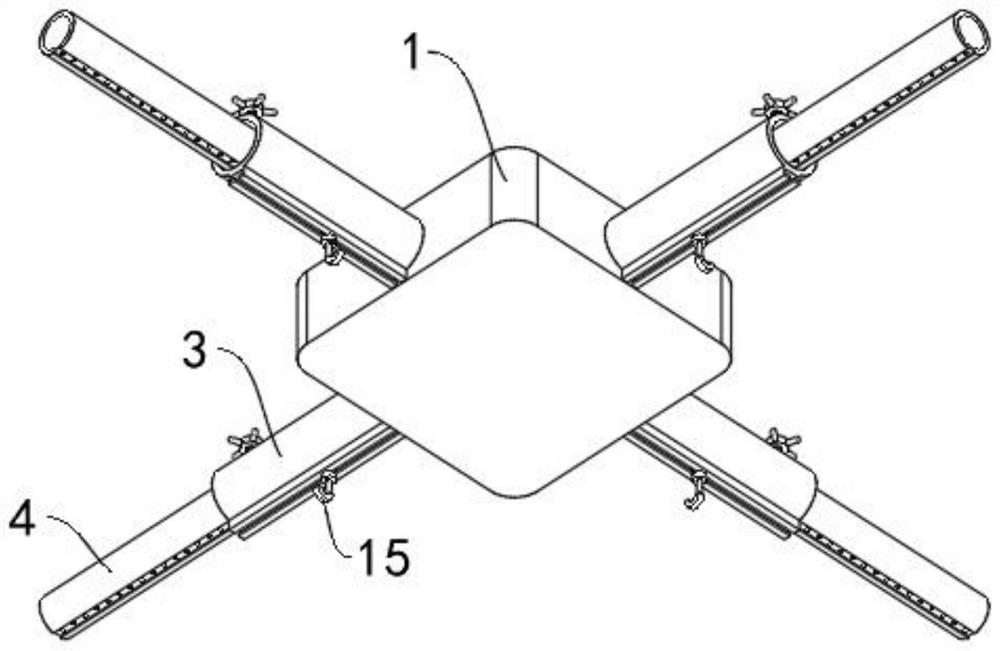

[0046] The following describes an unmanned aerial vehicle with a telescopic arm 2 according to Embodiment 2 of the present invention with reference to the accompanying drawings. Embodiment 2 is a further improvement on Embodiment 1.

[0047] like image 3 and Figure 5 As shown, the outer peripheral wall of the first arm 3 is provided with a hook 15 that can slide along the axial direction of the first arm 3, and the hook 15 is provided with a fixing part 16, and the fixing part 16 is used to fix the hook 15. On the first boom 3, the hook 15 provided can be used to hang some lighter items, thereby improving the carrying capacity of the drone, and the hook 15 can be moved so that its position can be flexibly adjusted.

[0048] like Figure 7 and Figure 8 As shown, the bottom of the outer peripheral wall of the first arm 3 is fixedly connected to the limit bar 14, and the limit bar 14 is provided with a slideway extending along the axial direction of the first arm 3. The hoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com