Liquid repairing agent for improving high-voltage and ultra-high-voltage cable water blocking buffer with electric corrosion and its preparation method, filling equipment and filling method

A technology for filling equipment and repairing agents, applied in the direction of insulated cables, cables, conductors, etc., can solve the problems of increased resistance of the water-blocking buffer zone, damage of the water-blocking buffer zone, cable breakdown, etc., to enhance the conductivity and reduce the repair Cost, effect of extending cable life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and comparative example 1

[0034] The composition ratio of the liquid repair agent for improving the electric corrosion of the water-blocking buffer belt of high-voltage and ultra-high-voltage cables in Examples 1-4 and Comparative Examples is shown in Table 1:

[0035] Table 1

[0036]

[0037] After the above components are weighed in proportion, first place graphite particles, silica spheres, and silane coupling agent in a stirrer, add absolute ethanol and stir thoroughly, and then place them in a drying room at 60-70°C for 4-8 hours. , to obtain a mixed powder, add polydimethylsiloxane to the mixed powder, place it in a three-roll mill for grinding and dispersing, and obtain a liquid restoration agent. In the preparation process, the graphite particles of Comparative Example 1 have poor dispersion and are easy to agglomerate, while the graphite particles of Examples 1-4 have good dispersion and are not easy to agglomerate. This is because the addition of a silane coupling agent can form a thin fi...

Embodiment 5

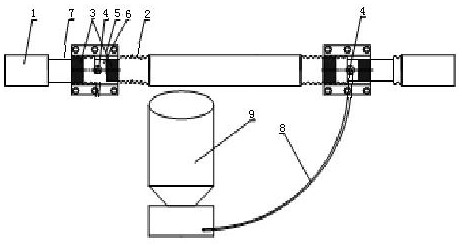

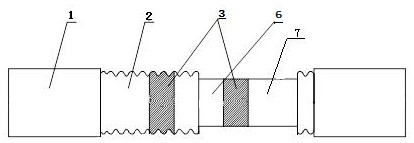

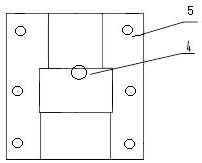

[0039] This embodiment provides a filling device for filling the liquid restoration agent of Embodiment 1-4, including a filling device body 9, a device connecting pipe 8 and a sealing fixture, and the sealing fixture includes a first sealing fixture and a second sealing fixture. The sealing fixture, the first sealing fixture and the second sealing fixture both include a semicircular shell, and the two sides of the shell are respectively provided with connecting plates 5, and the first sealing fixture and the second sealing fixture are connected by threads provided on the connecting plate 5, The casing of the first sealing fixture is provided with a repairing agent liquid inlet and outlet 4;

[0040] The method of use is:

[0041] S1: Strip off the cable outer sheath 1 with a length of 350-450mm at both ends of the cable that has been running or has undergone electrical corrosion of the water-blocking buffer belt, and exposes the wrinkled aluminum sheath 2;

[0042] S2: Along...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com