A special platinum vulcanizing agent for PA base material and silica gel combination without primer and its preparation

A platinum vulcanizing agent and platinum catalyst technology, which is applied in the field of polymers, can solve problems such as easy degumming, insufficient dimensional accuracy, insufficient hardness and elastic modulus, etc., and achieve high cross-linking density, high bonding strength, and the effect of improving bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

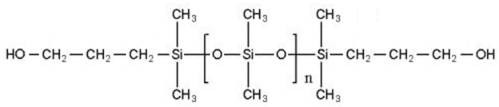

Method used

Image

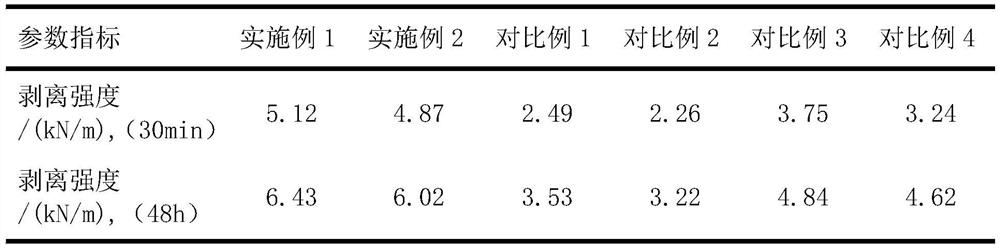

Examples

Embodiment 1

[0039] A special platinum vulcanizing agent for primer-free coating in combination with PA substrates and silica gel in this embodiment includes agent A and agent B, and each dosage form includes the following components in parts by weight:

[0040] Agent A: 45 parts of methyl vinyl silicone rubber (raw rubber, Dongjue silicone, molecular weight 600,000-800,000), platinum catalyst (1,3-divinyl-1,1,3,3-tetramethyl Platinum disiloxane (0), ~Pt 5000ppm solution) 50 parts, hydrophobic silica (Cabot TS720, specific surface area is 250-400m 2 / g) 10 parts;

[0041] Agent B: 65 parts of methyl vinyl silicone rubber (raw rubber, Dongjue silicone, molecular weight 600,000-800,000), vinyl hydrogen-containing silicone oil (XB-714, vinyl content 5%, hydrogen content 0.15% ) 45 parts, polysiloxane-polyurethane adhesive 40 parts, hydrophobic silica (Cabot TS720, specific surface area is 250-400m 2 / g) 10 parts, acetylenic alcohol compound inhibitor (acetylene cyclohexanol) 1 part.

[004...

Embodiment 2

[0048] A special platinum vulcanizing agent for primer-free coating in combination with PA substrates and silica gel in this embodiment includes agent A and agent B, and each dosage form includes the following components in parts by weight:

[0049] Agent A: 40 parts of methyl vinyl silicone rubber (raw rubber, Dongjue silicone, molecular weight 1.6-1.8 million), platinum catalyst (1,3-divinyl-1,1,3,3-tetramethyl Platinum disiloxane (0), ~Pt 5000ppm solution) 45 parts, hydrophobic silica (Cabot TS720, specific surface area is 250-400m 2 / g) 8 parts;

[0050] Agent B: 70 parts of methyl vinyl silicone rubber (raw rubber, Dongjue silicone, molecular weight 1.6-1.8 million), vinyl hydrogen-containing silicone oil (XB-714, vinyl content 0.25%, hydrogen content 1.0% ) 50 parts, polysiloxane-polyurethane adhesive 45 parts, hydrophobic silica (Cabot TS720, specific surface area is 250-400m 2 / g) 15 parts, acetylenic alcohol compound inhibitor (silanized acetylenic alcohol) 2 parts....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com