Preparation method of colored space-dyed loop yarn double-faced woolen cloth and prism vision detection device

A visual detection device and loop yarn technology, which is applied to measuring devices, yarns, and material analysis through optical means, can solve the problems of expensive jacquard machines and high costs for small and medium-sized enterprises, achieve delicate hand feeling and reduce labor intensity , the effect of tight texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015]Example one:

[0016]The present invention is a method for preparing double-faced colored loop-dyeing loop yarn, which includes the following steps: preparing loop yarn and then weaving fabric with a twill weave; the preparation of loop yarn includes the following steps: spinning nylon yarn into nylon The mink yarn is then dyed into sections of nylon mink yarn, and the section-dyed nylon mink yarn and polyester yarn are spun into loops.

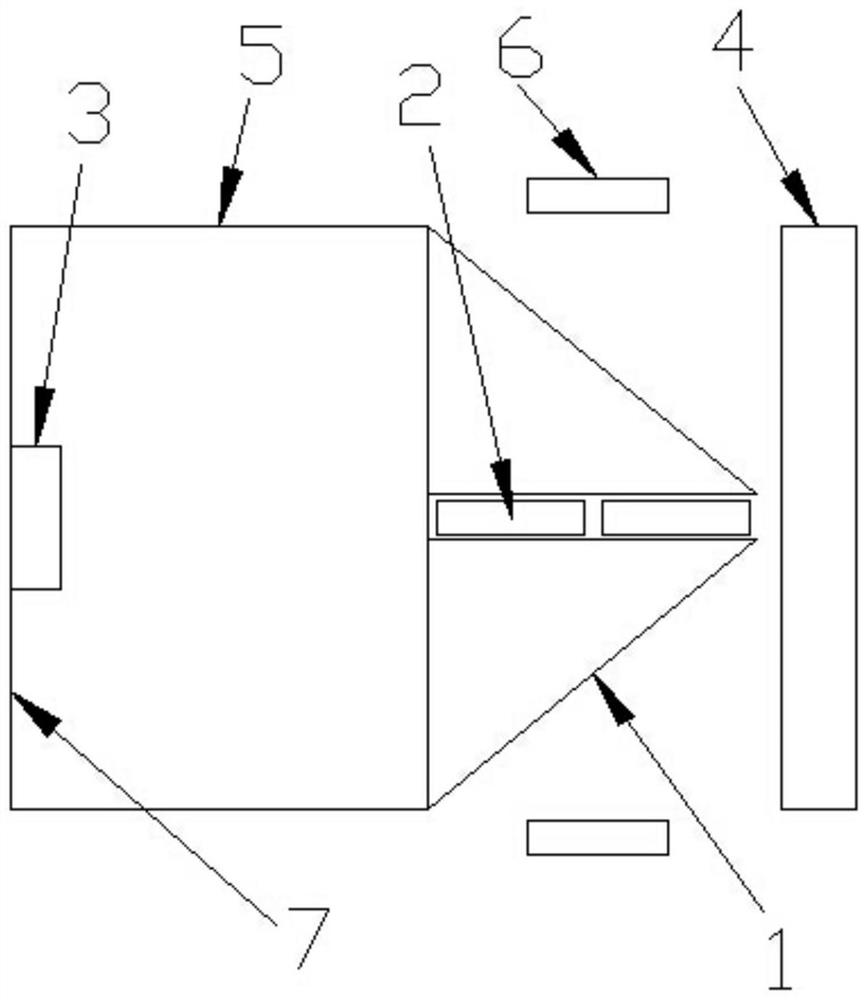

[0017]A triangular prism visual inspection device for double-sided fabric prepared by the method of preparing colored segment-dyed loop yarn double-sided fabric, such asfigure 1 As shown, it includes two right-angle prisms 1 arranged up and down. The material 2 to be tested is placed between the two right-angle prisms 1, and the camera 3 is set in the direction facing the side of the material 2. A material mirror plate 4 is set on the straight surface; the lens of the camera 3 can be rotated. The camera 3 is fixed on the middle of the vertical inne...

Example Embodiment

[0018]Embodiment two:

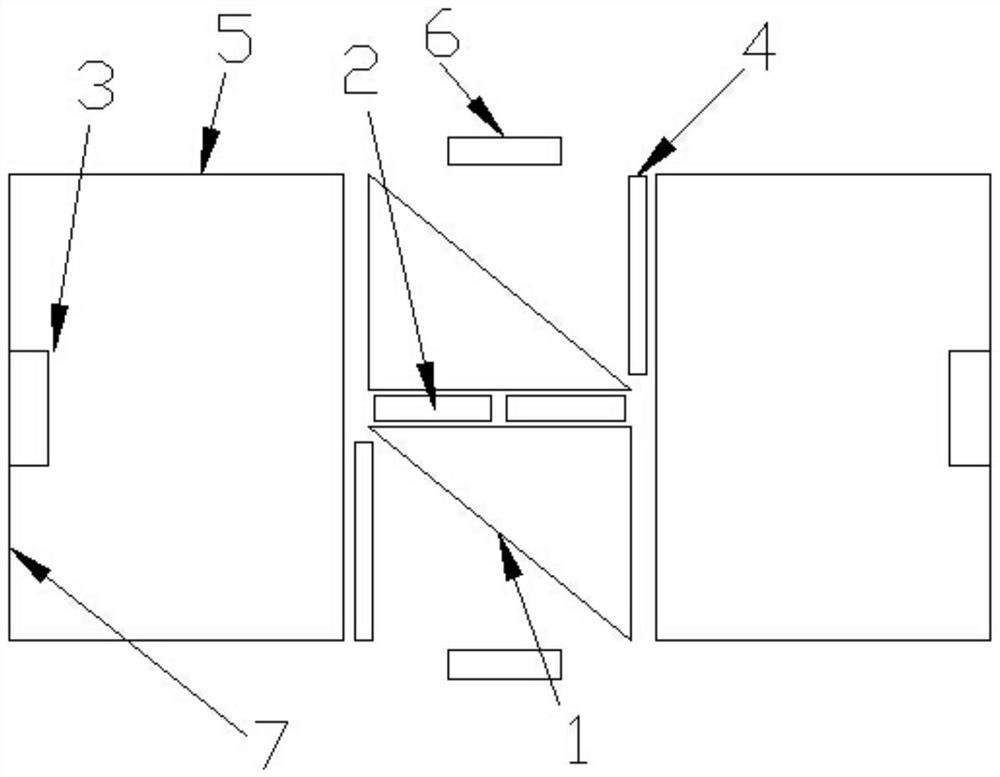

[0019]Such asfigure 2As shown, the only difference from the first embodiment is that two right-angle prisms 10 are arranged symmetrically with the center point of the material 2, and the material mirror plate 4 and the dust box 5 are both provided with two pieces, respectively located on the two sides of the material 2. On the other hand, the height of each material mirroring plate 4 is equal to half of the height of the dustproof box 5, and the number of the cameras 3 is two, which are respectively arranged in the middle of the vertical inner walls 7 of the two dustproof boxes 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com