Drum washing machine and control method thereof

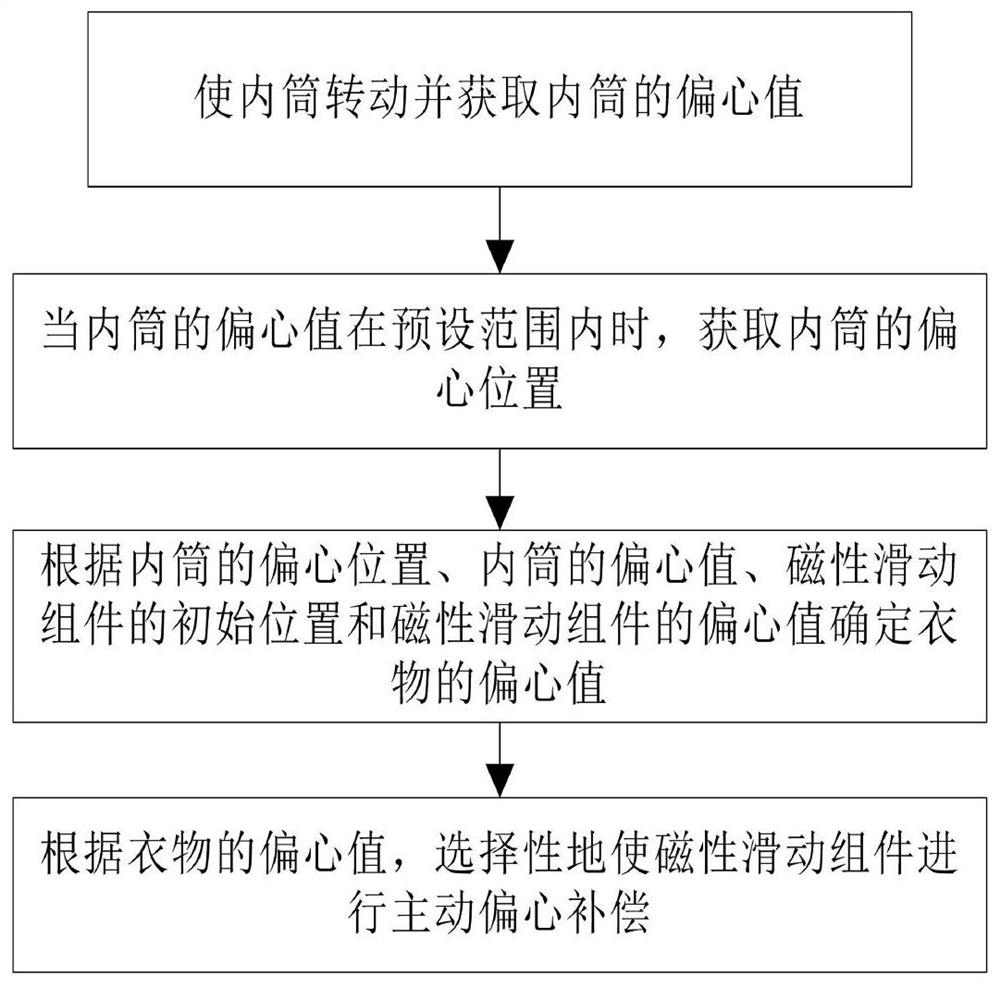

A technology of a drum washing machine and a control method, which is applied to the control device of the washing machine, other washing machines, washing devices, etc., can solve the problems of long time for eccentric compensation, inability to realize, limited eccentric effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

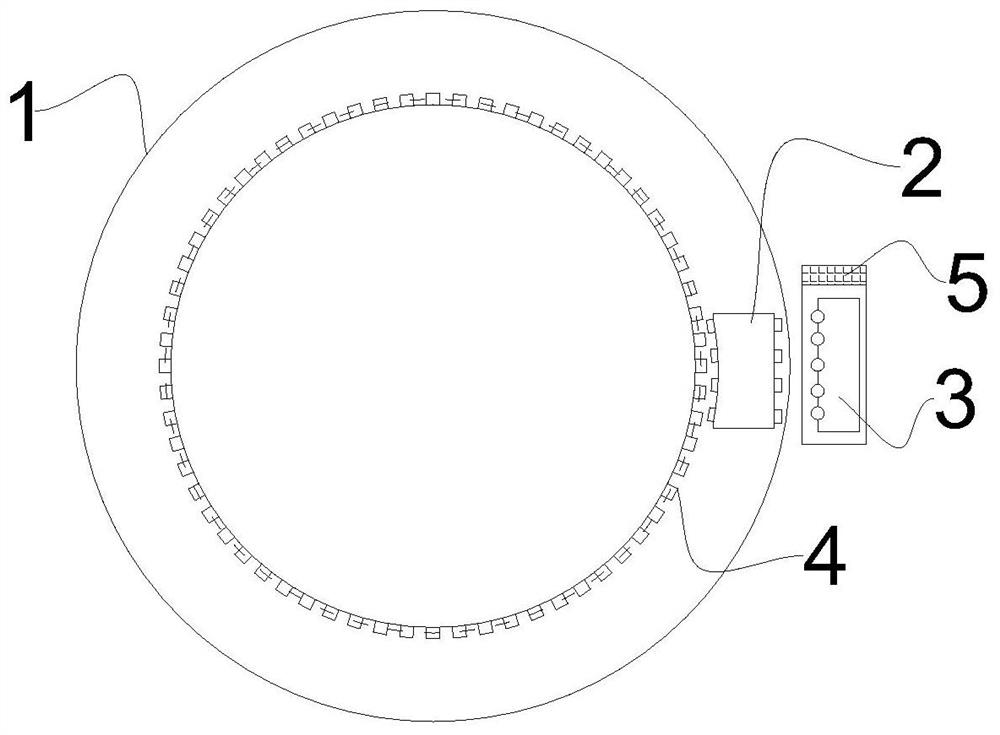

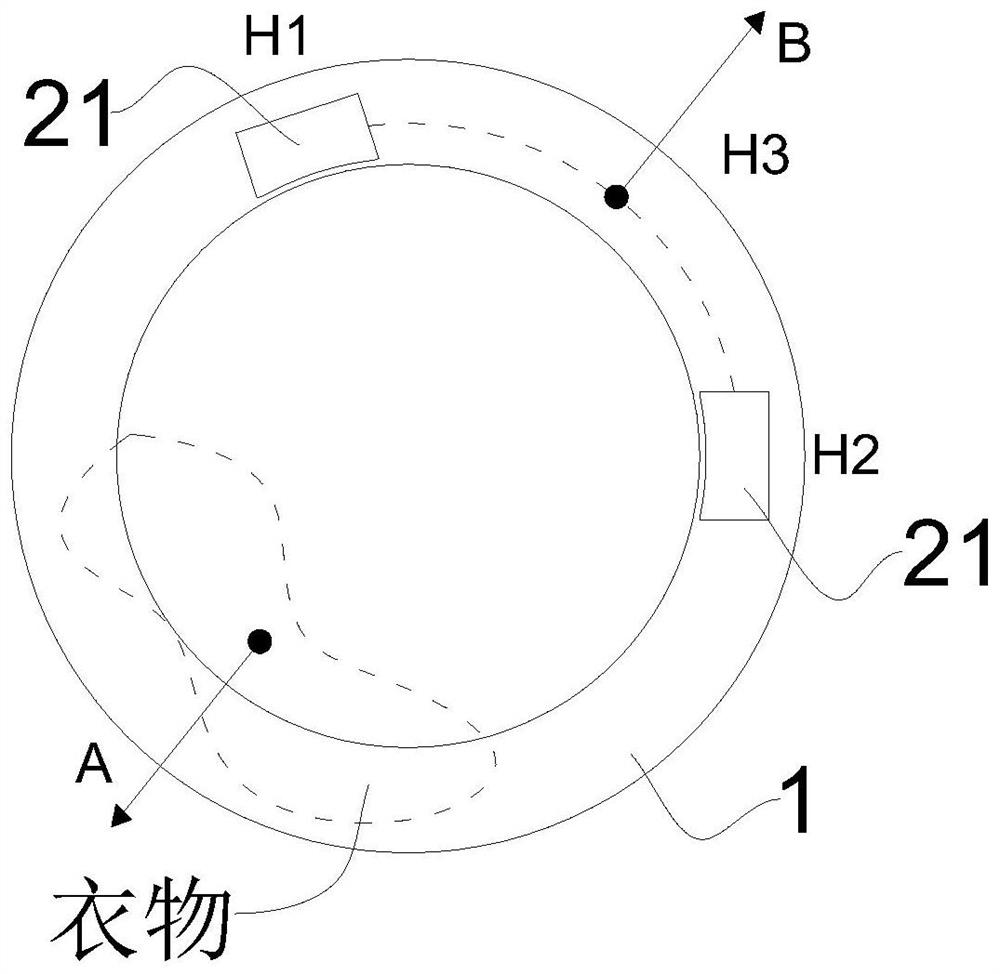

[0033] The locking assembly 4 is an elastic locking assembly, and the elastic locking assembly includes a spring, a sliding piece and a locking piece, wherein the sliding piece is connected to the sliding groove on the inner wall of the balance ring 1 (the sliding groove is along the circumferential direction of the inner wall of the balancing ring 1 Setting) sliding connection, the two ends of the spring are respectively connected with the sliding part and the magnetic slider 21, and the locking part includes a plurality of locking suction cups arranged circumferentially along the inner wall of the balance ring 1, when the electromagnetic adsorption assembly 3 is not energized, the spring Under the active force, one or several locking suckers will absorb the magnetic slider 21. When the electromagnetic adsorption component 3 is energized, the magnetic attraction force of the electromagnetic adsorption component 3 to the magnetic slider 21 is greater than the elastic force of th...

Embodiment 2

[0035] The locking assembly 4 is a magnetic locking assembly, which includes a magnetic slide rail and a locking piece, wherein the magnetic slide rail is arranged along the circumferential direction of the inner wall of the balance ring 1, and the locking piece includes a magnetic slide rail along the circumferential direction of the inner wall of the balance ring 1. The plurality of locking suckers provided, when the electromagnetic adsorption assembly 3 is not powered on, under the action of the magnetic attraction force of the magnetic slide rail on the magnetic slider 21, one or several locking suckers will absorb the magnetic slider 21, and the magnetic slider will When the adsorption assembly 3 is powered on, the magnetic attraction force of the electromagnetic adsorption assembly 3 to the magnetic slider 21 is greater than the magnetic attraction force of the magnetic slide rail to the magnetic slider 21, so that the electromagnetic adsorption assembly 3 will suck the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com