A hoisting structure for a prefabricated building insulation board and its application method

A technology of building thermal insulation and thermal insulation boards, which is applied in the direction of building components, building structures, buildings, etc., can solve the problems of thermal insulation boards slipping, inconvenient hoisting, hidden safety hazards, etc., and achieve the effect of easy hoisting, convenient hoisting, and firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

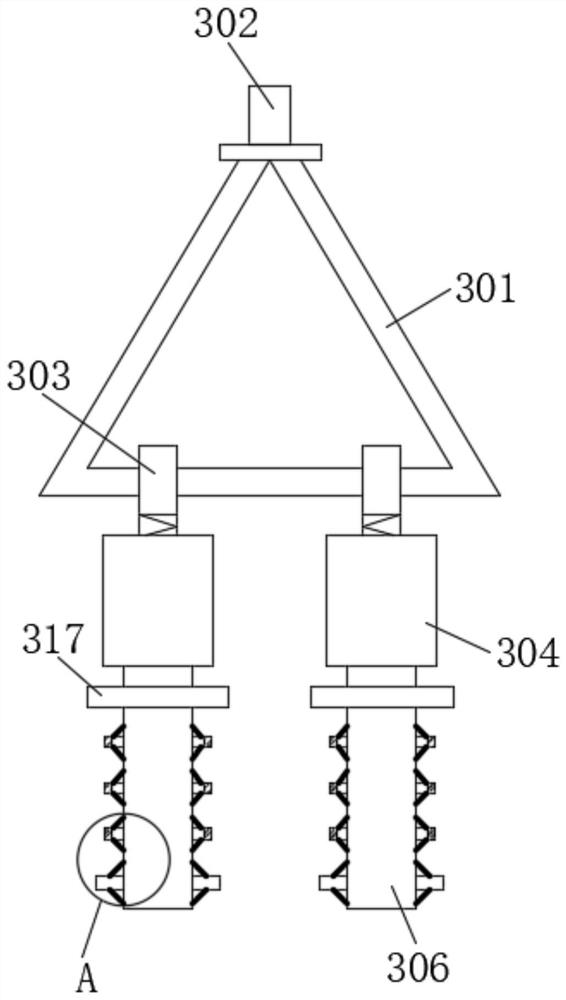

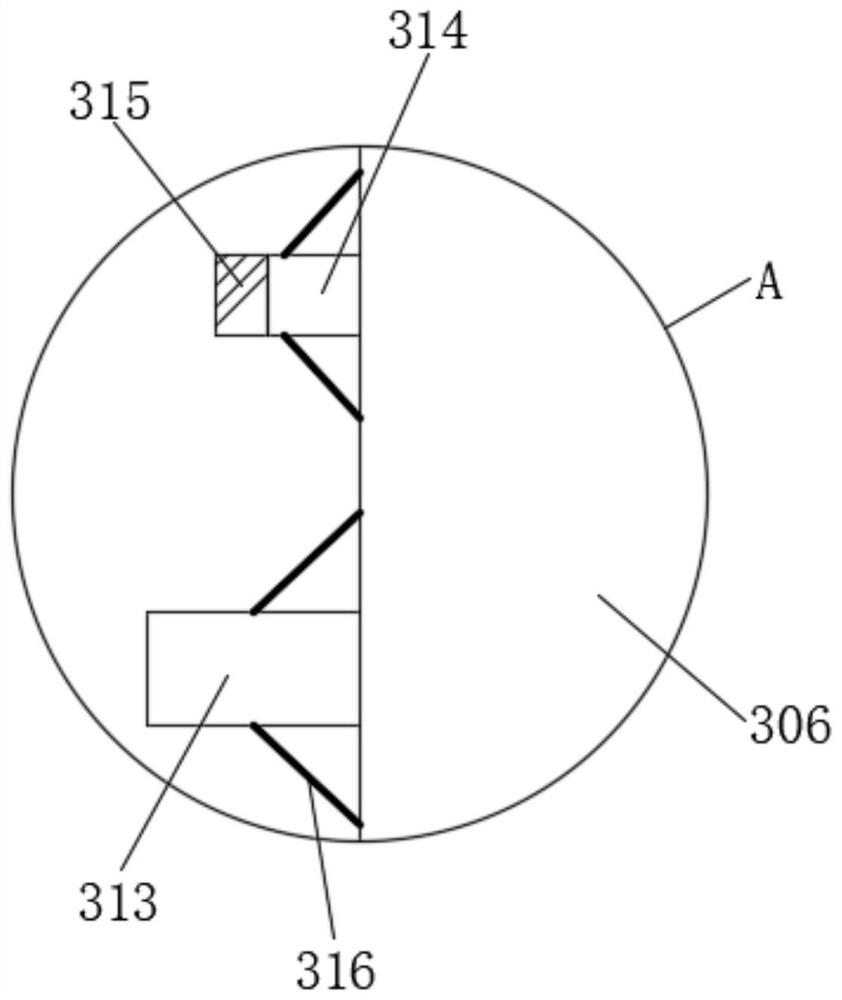

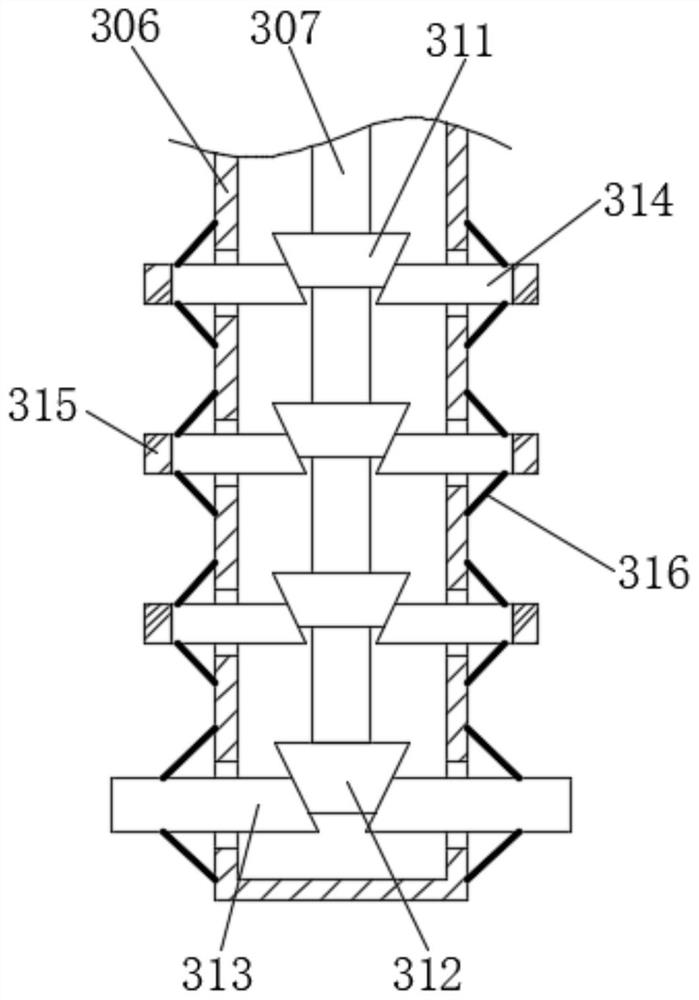

[0044] see figure 1 with Figure 5-6 , a hoisting structure for a prefabricated building thermal insulation board, including a thermal insulation board and a hoisting structure, the thermal insulation board includes a main board body and an assembly plug, the main board body includes a thermal insulation board main body 101, and two symmetrically arranged hoisting holes are opened in the thermal insulation board main body 101 102, the upper and lower ends of each hoisting hole 102 are provided with a sealing gap hole 103, the assembly plug includes a heat preservation hole plug 201 that matches the hoisting hole 102, and one end of the heat preservation hole plug 201 is fixedly connected with a heat preservation hole plug 201. Matching thermal expansion plugs 202, one main body is provided with four assembly plugs, the inner diameter of the sealing hole 103 is larger than the hoisting hole 102, the length of the heat preservation hole plug 201 is half of the depth of the hoist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com