Method for determining fireflooding combustion temperature of heavy oil reservoir by utilizing iron-containing minerals

A technology for heavy oil reservoirs and combustion temperature, which is applied in earth-moving drilling, fluid production, wellbore/well components, etc., can solve the problems of high cost, single monitoring object, and inability to monitor the temperature of reservoirs by fire flooding.

Pending Publication Date: 2021-01-29

PETROCHINA CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the commonly used fire flooding temperature monitoring method is to arrange thermocouples in the development well to monitor the temperature of the ignition well or the well at a certain depth. temperature monitoring

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0035] This embodiment provides a method for determining the fire flooding combustion temperature of heavy oil reservoirs by using iron-containing minerals for Block D of Liaohe Oilfield, wherein the method includes the following specific steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

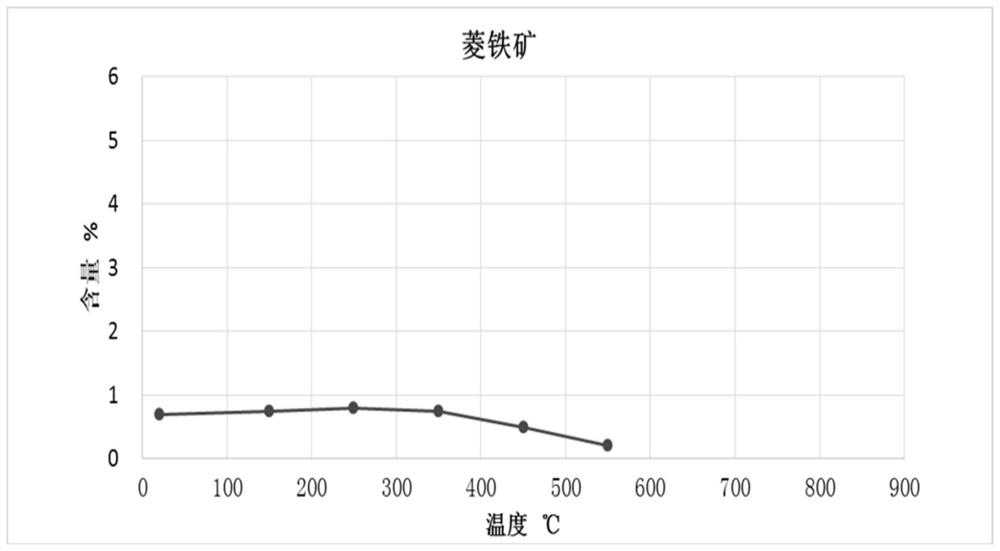

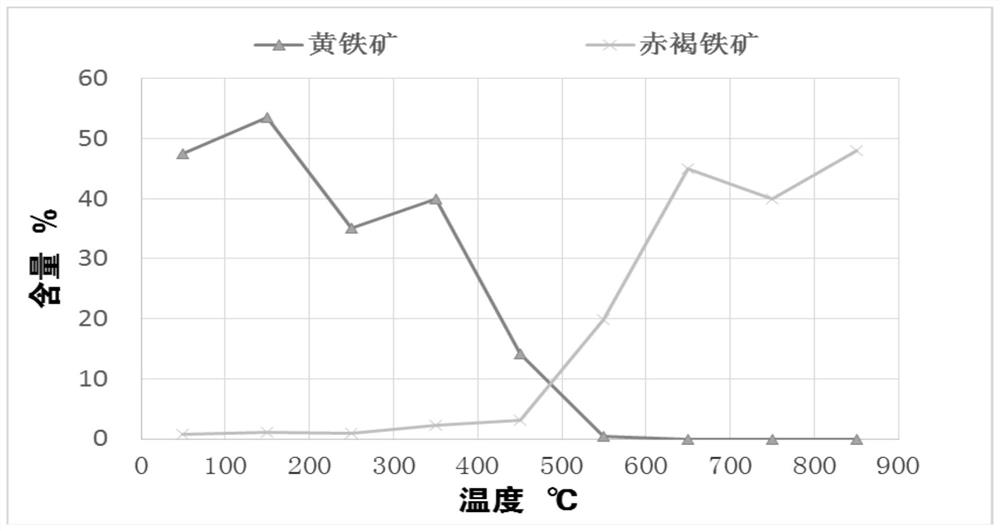

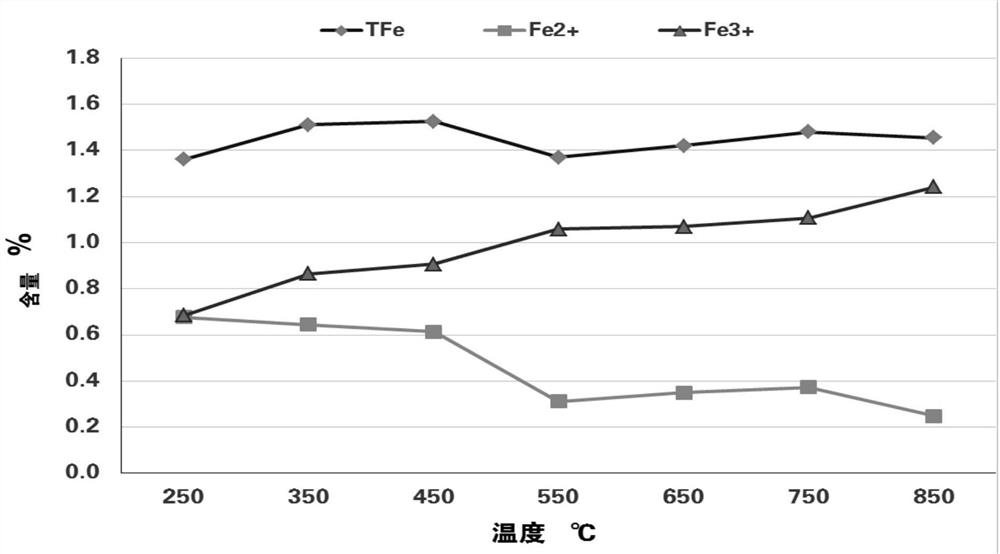

The invention provides a method for determining the fireflooding combustion temperature of a heavy oil reservoir by using iron-containing minerals. The method comprises the following steps of carryingout a calcination test on a core in a target research area under different temperature conditions, and carrying out whole-rock quantitative analysis on the core after the core is cooled to obtain thesiderite content in the core under different calcination temperature conditions and the relationship between the siderite content and the temperature; carrying out heavy mineral analysis on the cooled rock core so as to determine the content of iron-containing minerals in the heavy minerals under different calcination temperature conditions and the relationship between the iron-containing minerals and the temperature; carrying out trace element analysis on the cooled rock core so as to determine the contents of total iron, Fe<2+> and Fe<3+> in the iron-containing minerals under different calcination temperature conditions and the relationship between the contents and the temperature; analyzing the change rule of the color of the cooled rock core, and establishing a rock core color code plate; and determining the fireflooding combustion temperature of the heavy oil reservoir according to the relationship between the siderite content, the iron-containing mineral content, the total ironcontent, the Fe<2+> content and the Fe<3+> content in the rock core and the temperature and one or more of the rock core color code plates.

Description

technical field [0001] The invention relates to a method for determining the fire flooding combustion temperature of heavy oil reservoirs by using iron-containing minerals, and belongs to the technical field of petroleum development. Background technique [0002] Fire flooding is a thermal oil recovery method that generates heat inside the oil layer to cause high-temperature oxidation reaction between crude oil and injected air or oxygen, releases a large amount of heat and gas, and displaces unburned crude oil to production wells. This method has no heat loss along the wellbore, and has the advantages of high recovery, low cost and wide application range, and can be used as an effective replacement technology after steam huff and puff in heavy oil reservoirs. During the fire flooding process, determining the underground combustion temperature is helpful to understand the fire flooding combustion state (high-temperature combustion or low-temperature combustion), and timely a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21B49/00E21B49/02E21B43/243E21B47/07

CPCE21B49/00E21B49/02E21B43/243

Inventor 史海涛武毅马宏斌刘其成董文波尉小明李蔓魏耀李金有李思圻韩洪斗齐庆鹏闫红星刘玉婷张翔宇

Owner PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com