Large-mining-height rib-spalling-preventing coal anchoring and roof grouting device and use method thereof

A technology with large mining height and sidewalls, which is applied in mining equipment, earthwork drilling, installation of bolts, etc., and can solve problems such as roof fall of the sidewalls and threats to personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

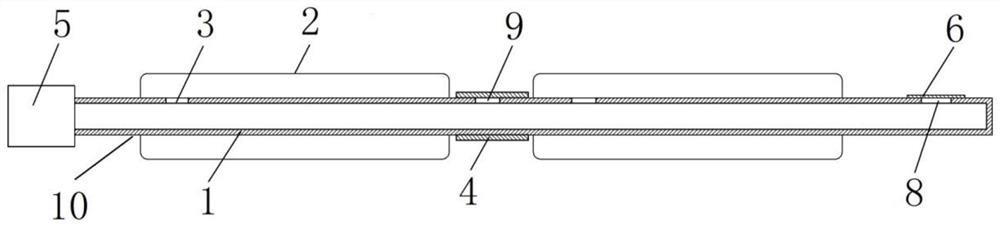

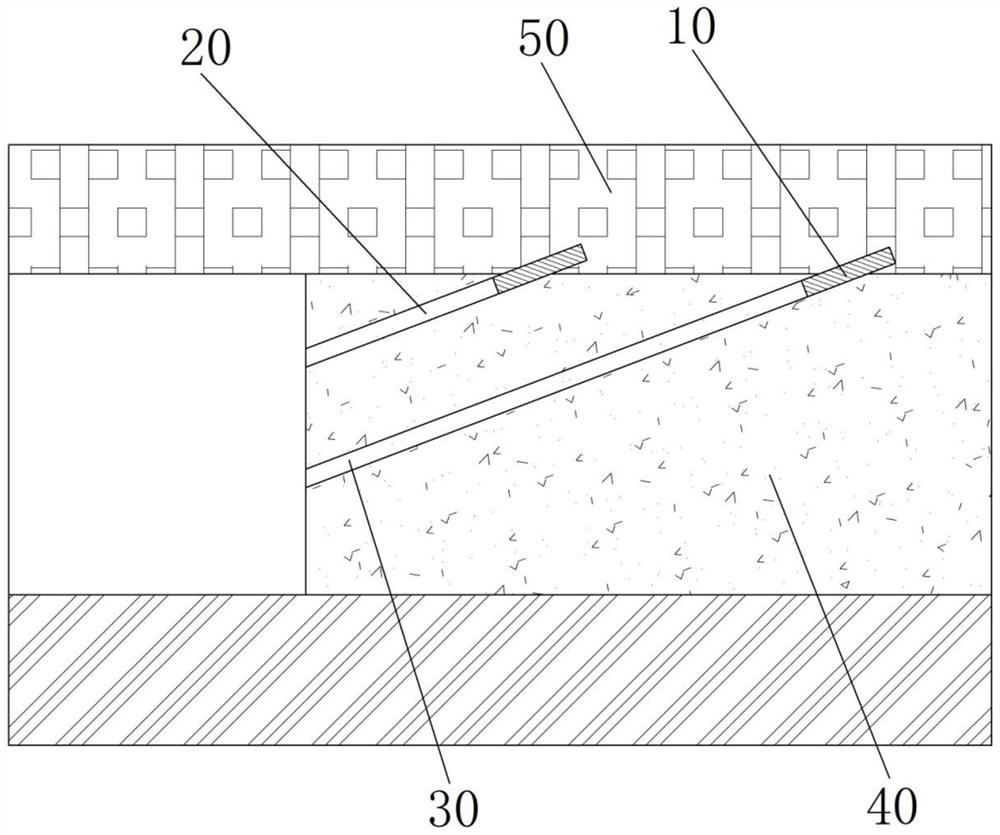

[0036] According to specific embodiments of the present invention, such as figure 1 and image 3 As shown, the present invention provides a kind of anchor coal roof injection device for large mining height and anti-slab side.

[0037] The anchor coal top injection device 10 includes a grouting pipe 1, a bag 2 and a blasting structure. Grouting pipe 1 is the passage of grouting liquid; Grouting pipe 1 is a flexible pipe, optional plastic pipe during concrete implementation, the material of plastic pipe is nylon or aluminum-plastic, and the diameter scope of plastic pipe is 18-22mm (can choose 18mm , 19mm, 20mm, 21mm, 22mm), the thickness of the plastic pipe is 2-4mm (2mm, 3mm, 4mm can be selected). The pipe made of plastic makes the grouting pipe 1 flexible and can be rolled up. The bladder 2 is arranged on the periphery of the grouting pipe 1, and the position corresponding to the bladder 2 on the grouting tube 1 is provided with a first grout outlet 3, and the grouting liq...

Embodiment 2

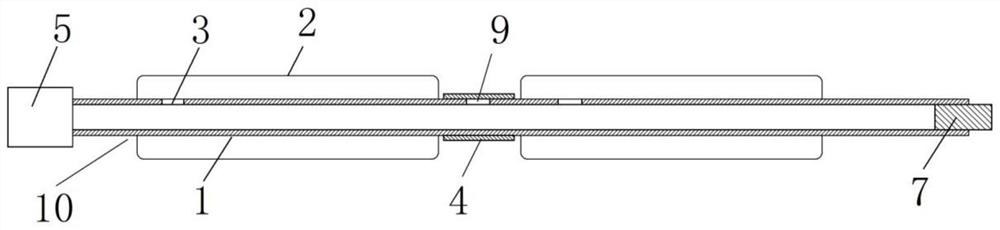

[0048] According to specific embodiments of the present invention, such as figure 2 As shown, the present invention provides a second embodiment of an anchor coal roof injection device with a large mining height and anti-slab side. The difference between this embodiment 2 and embodiment 1 is only the blasting structure; in embodiment 2, the blasting structure Including the blasting plug 7, the blasting plug 7 is blocked at the port position of the grouting pipe 1, and when the grouting pressure reaches the set value, the grouting liquid will rush the blasting plug 7 out of the grouting pipe 1; The depth that the plug 7 extends into the grouting pipe 1 is used to adjust the pressure setting value; that is, the deeper the blasting plug 7 is inserted into the grouting pipe 1, the greater the pressure required to push the blasting plug 7 out . The blasting plug 7 is directly set to block the port position of the grouting pipe 1, the structure is simple, and the installation and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com