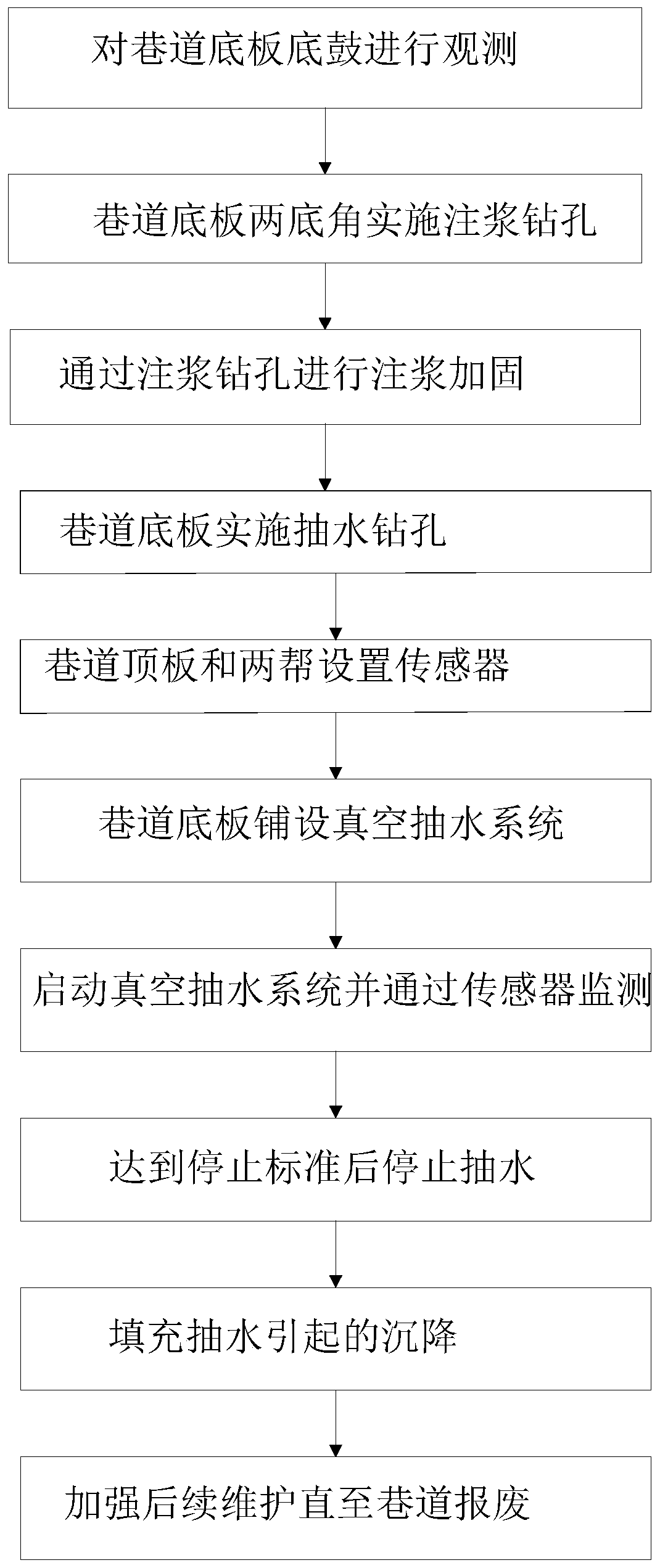

A treatment method for water-absorbing floor drum of coal mining roadway floor

A technology of floor and roadway, applied in tunnels, drainage, mining equipment and other directions, can solve the problems of high cost and technical requirements, long construction period, poor sealing, etc., and achieve the effect of good drainage effect, wide water pumping range and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

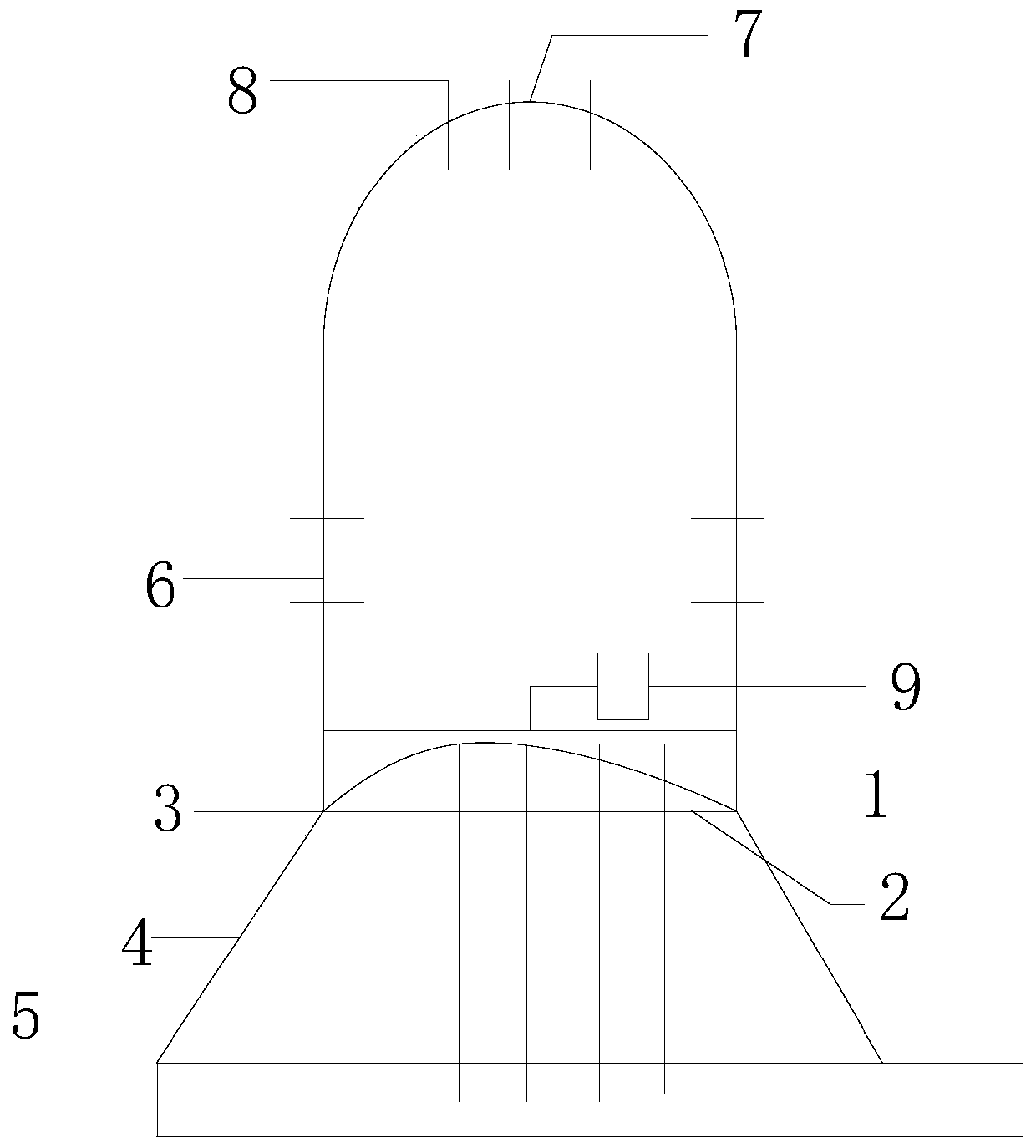

[0052] A coal mine mines No. 5 coal. Before mining 5001, it is necessary to develop 2 roadways. Floor heaving occurred in the development stage of No. 1 roadway. The floor heaving in the 74-82 meter section of No. 1 roadway has affected the production, and the floor heaving occurred after the bottom plate absorbed water. Therefore, the following steps were taken to achieve success in coal mining:

[0053] Step 1: Observing the floor heave of the roadway floor. Observe that the maximum height of the bottom plate is h is 0.5 meters, and the plane position where the maximum height is located, the coordinates are (1, 3).

[0054] Step 2: Carry out grouting drilling at the two bottom corners of the roadway floor, and implement a total of 6 grouting drilling holes on both sides. The distance between adjacent grouting drill holes on the same side is less than twice the grout diffusion radius, where the grout diffusion radius is 2m obtained by the established field test method. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com