Preparation method of heavy corrosion protection primer resin

A heavy-duty anti-corrosion primer and resin technology, applied in the field of coatings, can solve the problems of reduced bonding force between the coating film and the substrate, coating damage, anti-corrosion performance, poor toughness, etc., and achieve excellent medium resistance and anti-corrosion performance. Medium resistance and corrosion resistance, excellent effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

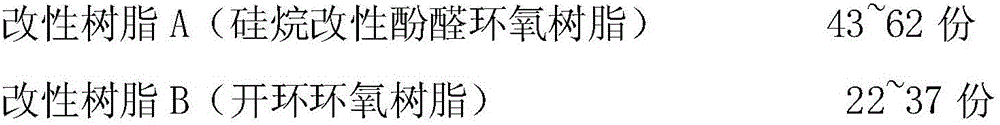

Method used

Image

Examples

Embodiment 1

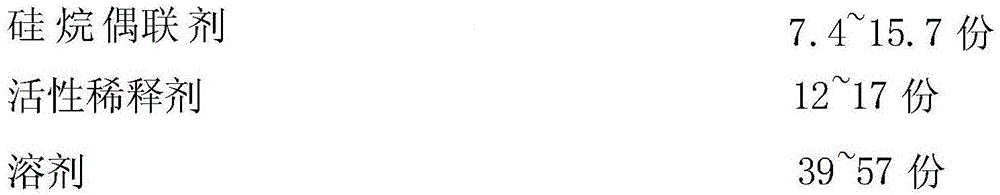

[0035] Add 62g of EPN-1179, 8g of n-butyl acetate, and 12g of cyclohexanone into the reaction flask, raise the temperature to 95°C under the protection of nitrogen, and start to drop the mixture of 5.7g of γ-aminopropyltriethoxysilane and 18g of xylene, After 2 hours of dropwise addition, heat preservation was carried out for 3 hours, the temperature was lowered, and the material was discharged for subsequent use to obtain modified resin A (silane-modified novolac epoxy resin).

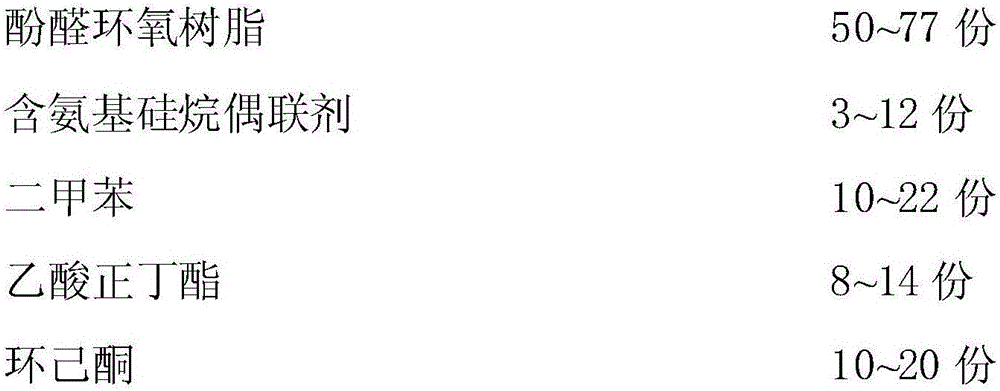

[0036] Add 92g of E-20, 23g of coconut oleic acid, 10g of xylene and 60g of cyclohexanone into another reaction flask, raise the temperature to 160°C under the protection of nitrogen, keep the temperature for 10 hours, cool down, discharge the material for later use, and obtain a modified resin B (ring-opening epoxy resin).

[0037] Add 52g of modified resin A, 26g of modified resin B, 8.2g of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 15.5g of polypropylene glycol diglycidyl ether and 41g of methyli...

Embodiment 2

[0039] Add 35g EPN-1179, 28g EPN-1138, 14g n-butyl acetate, 20g cyclohexanone into the reaction flask, raise the temperature to 95°C under the protection of nitrogen, and start to drop 10.6g N-phenyl-α-aminomethyl The mixture of triethoxysilane and 12g of xylene was added dropwise for 2 hours and then kept for 3 hours, cooled and discharged for later use to obtain modified resin A (silane-modified novolac epoxy resin).

[0040] Add 122g of E-12, 18g of soy oil, 30g of xylene and 50g of cyclohexanone into another reaction flask, raise the temperature to 155°C under the protection of nitrogen, keep it warm for 10 hours, cool down, discharge the material for later use, and obtain modified resin B (ring-opening epoxy resin).

[0041] Add 47g of modified resin A, 32g of modified resin B, 5g of dodecafluoroheptylpropyltrimethoxysilane, 4g of γ-mercaptopropyltrimethoxysilane, and 12g of 1,6-hexanediol diglycidyl into the packaging barrel Ether and 48g n-pentyl acetate, obtain the he...

Embodiment 3

[0043] Add 70g of GY-289, 9g of n-butyl acetate, and 18g of cyclohexanone into the reaction flask, raise the temperature to 95°C under the protection of nitrogen, and start to drop 3.3g of γ-aminopropyltriethoxysilane, 2.9g of N-β -(Aminoethyl)-γ-aminopropylmethyldimethoxysilane and 22g xylene mixture, after 2 hours of dropwise addition, keep warm for 3 hours, cool down, discharge for later use, and obtain modified resin A (silane modified novolac epoxy resin).

[0044] Add 64gE-12, 33gE-20, 21g soy oil, 17g xylene and 55g cyclohexanone to another reaction flask, raise the temperature to 160°C under the protection of nitrogen, keep it warm for 10 hours, cool down, discharge the material for later use, and obtain Modified resin B (ring-opening epoxy resin).

[0045]Add 60g of modified resin A, 33g of modified resin B, 12.1g of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 6.3g of polypropylene glycol diglycidyl ether, 6.7g of phenyl Glycidyl ether and 42g pimelinketone were mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com