Steel-plastic composite pipe connecting mechanism

A technology of steel-plastic composite pipe and connection mechanism, which is applied in the direction of mechanical equipment, cleaning methods and appliances, chemical instruments and methods, etc., can solve problems such as damage to the joint of steel-plastic composite pipe, blockage of the joint, and influence on use, so as to reduce The effect of working intensity, avoiding normal use, and facilitating work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

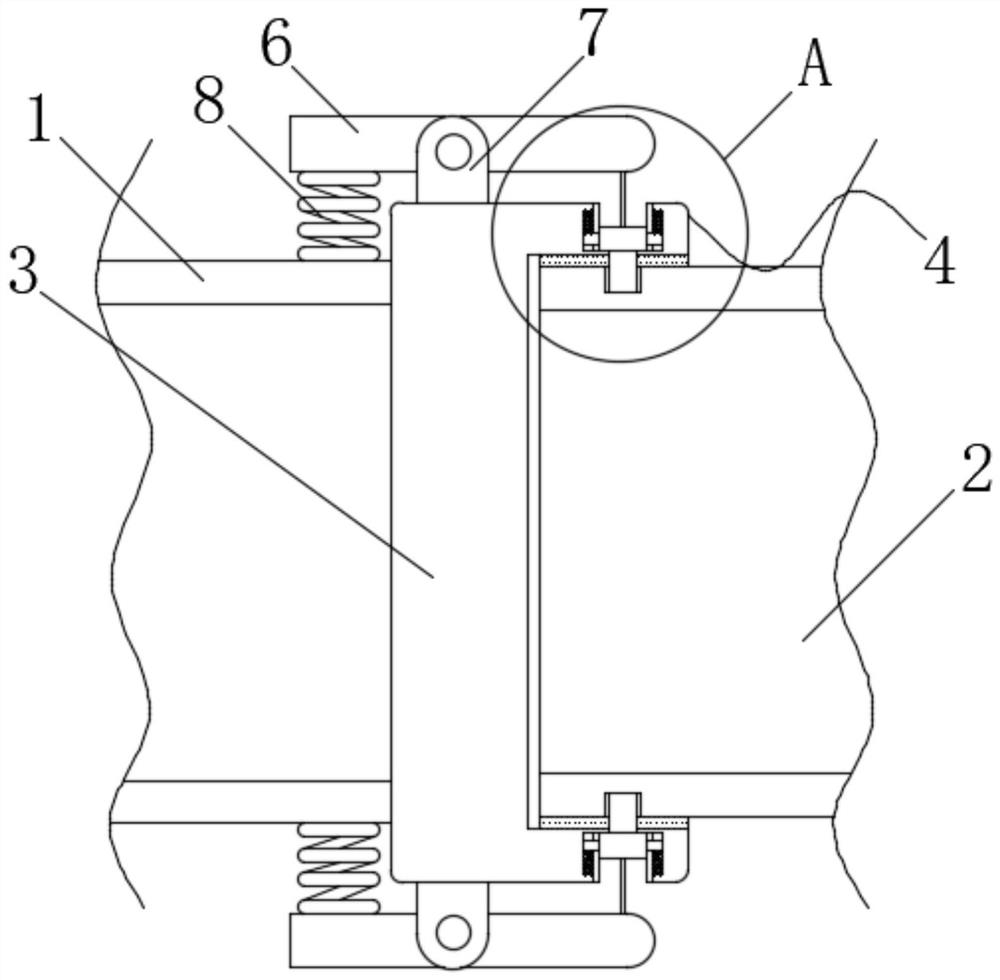

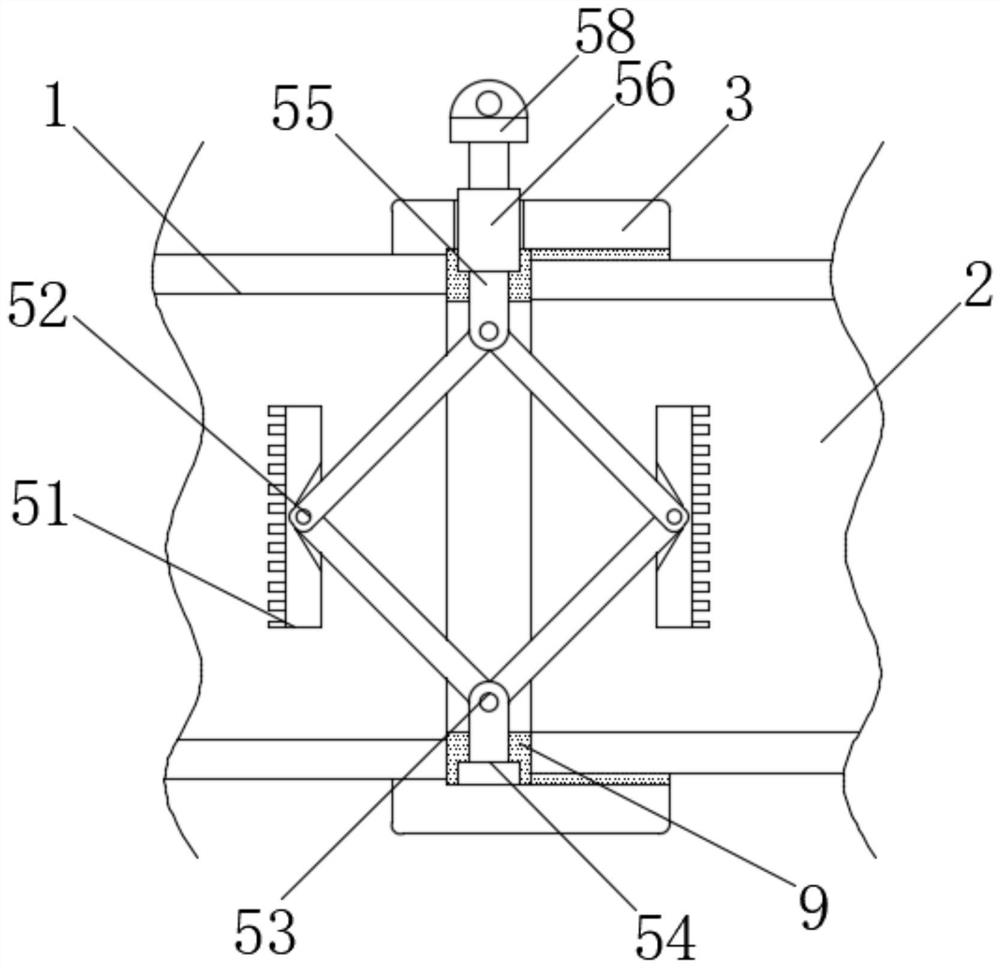

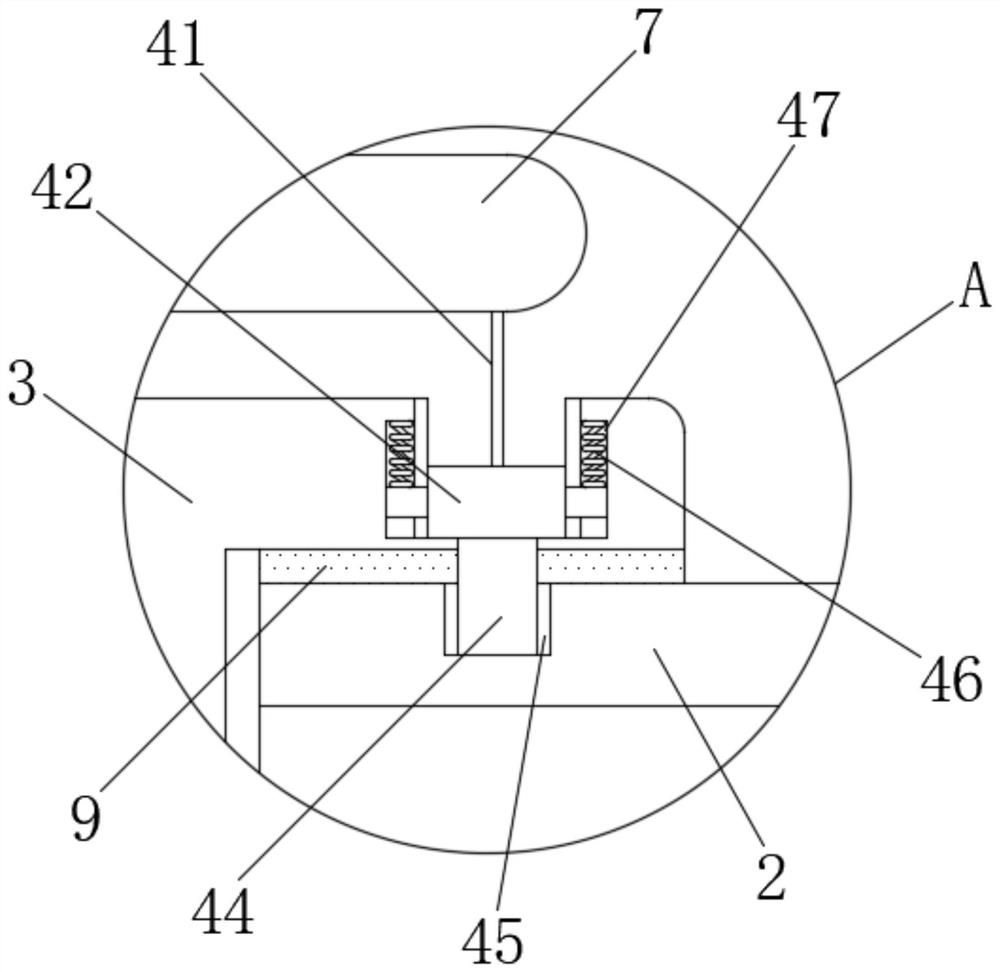

[0026] Such as Figure 1-3 As shown, the present invention provides a steel-plastic composite pipe connection mechanism, including: a first pipe 1, a second pipe 2, a fixing mechanism 4 and a cleaning mechanism 5; the right side of the first pipe 1 is clamped with a fixing frame 3. The upper and lower sides of the fixed frame 3 are provided with through holes, and a fixed mechanism 4 is arranged in the through holes. The front of the fixed frame 3 is provided with a limit hole, and a cleaning mechanism 5 is arranged in the limit hole; the fixed mechanism 4 includes : sling 41, limit block 42, block 44, draw-in groove 45, second spring 46 and chute 47; wherein, the left and right sides of described through hole are all provided with chute 47, slide connection in chute 47 There are sliders, and the opposite surfaces of the two sliders are respectively fixedly connected to the left and right side surfaces of the limiting block 42 , and the second spring 46 is arranged in the slid...

Embodiment 2

[0036] This embodiment provides a steel-plastic composite pipe connection mechanism, which differs from Embodiment 1 in that, as figure 2 As shown, one side of the cleaning plate 51 is provided with a plurality of bristles, and the plurality of bristles are evenly arranged on the surfaces of the two cleaning plates 51 that are far away from each other.

[0037] In practical applications, when the two cleaning plates 51 are far away from each other to a certain extent, the bristles will stick to the joint, so that when the workers rotate the twist ring, the cleaning plate 51 can drive the bristles to clean on the inner wall of the joint. So as to achieve a more perfect cleaning and ensure the cleaning effect during cleaning.

Embodiment 3

[0039]This embodiment provides a steel-plastic composite pipe connection mechanism, which differs from Embodiment 1 in that, as figure 1 As shown, a first spring 8 is fixedly connected to the lower surface of the cross bar 6 , and the other ends of the two first springs 8 are fixedly connected to the upper and lower sides of the first pipe 1 respectively.

[0040] In practical application, when the workers press one end of the cross bar 6, it can drive the one ends of the two cross bars 6 close to each other, thereby receiving the rebound force of the two first springs 8, thereby returning to the original position, ensuring that when the workers When we press one end of the cross bar 6, the cross bar 6 can return to the original position more stably, avoiding the situation that the cross bar 6 is dislocated due to its own reasons.

[0041] Working principle, when workers are in use, they can press one end of the two crossbars 6 to make the two ends of the two crossbars 6 appro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com