A screening processing device for agglomerated flour after secondary processing

A technology of secondary processing and processing equipment, which is applied in the directions of filtering, sieving, transportation and packaging, and solid separation. Novel internal structure design, excellent screening and processing effects, and optimized processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

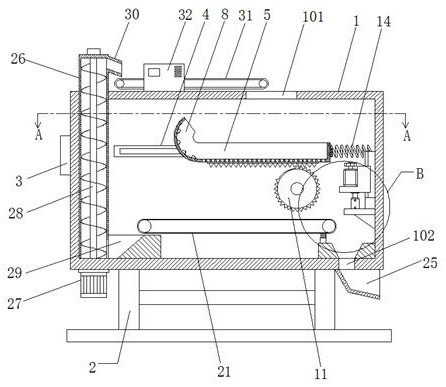

[0032] This embodiment 1 discloses a sieving processing device after secondary processing of agglomerated flour, refer to the attached figure 1 , its main structure includes a screen box 1, and a control panel 3 is arranged on the outer surface of the screen, and the control panel 3 is used to control the start and stop of the electrical components in the entire device. A support frame 2 is connected to the lower end of the screen box 1, and the whole support frame 2 is composed of several legs and a bottom plate, thereby playing a good role in fixing the screen box 1.

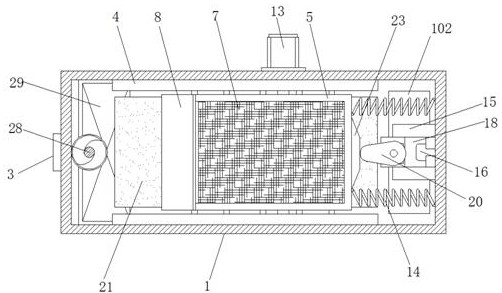

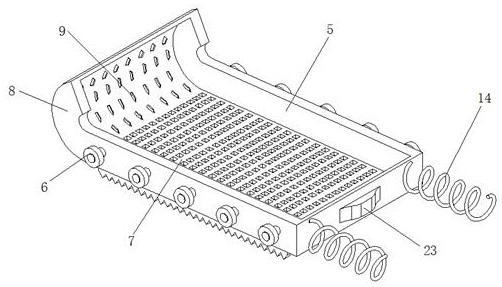

[0033] Reference attached figure 1 And attached figure 2 A horizontal rail 4 is fixedly connected to the front and rear side walls of the screen box 1 , and a rectangular screen frame 5 is arranged between the two horizontal rails 4 . Reference attached image 3 And attached Figure 4 A plurality of rollers 6 are rotatably connected to the front and rear sides of the rectangular screen frame 5, and severa...

Embodiment 2

[0040] This embodiment 2 discloses a screening processing device after secondary processing of agglomerated flour improved on the basis of embodiment 1.

[0041] The similarities between Embodiment 2 and Embodiment 1 will not be described again. For the differences, refer to the appended figure 1 , the present embodiment 2 is also provided with a vertically upward auger cylinder 26 at the inner left end of the screen box 1, and the upper end of the auger cylinder 26 protrudes from the upper surface of the screen box 1 and is set. An auger motor 27 is arranged on the lower surface of the sieve box 1 directly below the auger cylinder 26, and the rotating shaft of the auger motor 27 extends into the auger cylinder 26. The end of the auger cylinder 26 is connected with an auger transport leaf 28, and the The right side of the lower end of the body 26 is provided with a feeding port (not marked in the figure). Then, a collecting tank 29 is also arranged directly below the left end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com