Parallel Controlled Overturning System and Parallel Control Method

A technology of parallel control and steel turning, which is applied in the field of metallurgical steelmaking, can solve the problems of manual control of turning over, reducing the efficiency of turning over, and statistical errors in turning over, so as to ensure continuous and stable production of continuous casting, efficient and coordinated control methods, The effect of shortening the steel turning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

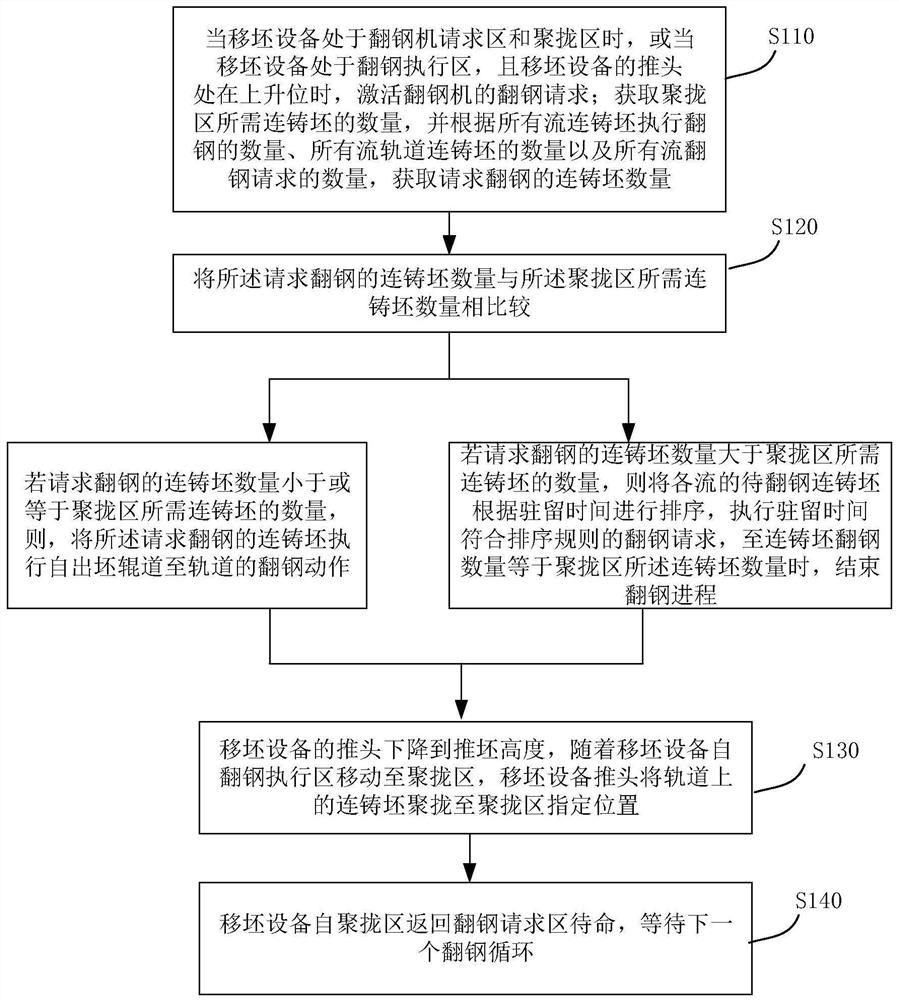

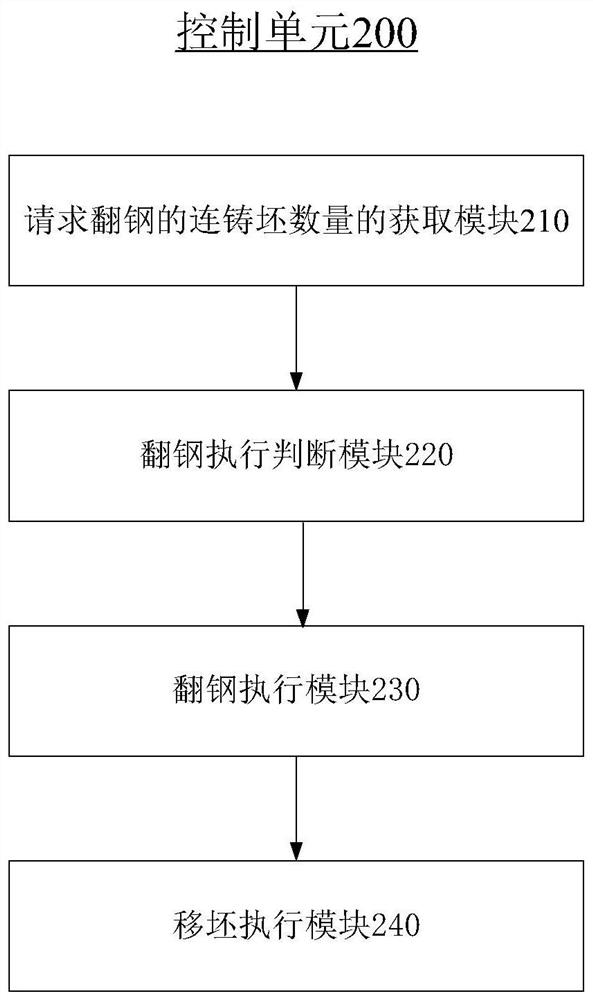

Method used

Image

Examples

Embodiment Construction

[0047] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details. In other instances, well-known structures and devices are shown in block diagram form in order to facilitate describing one or more embodiments.

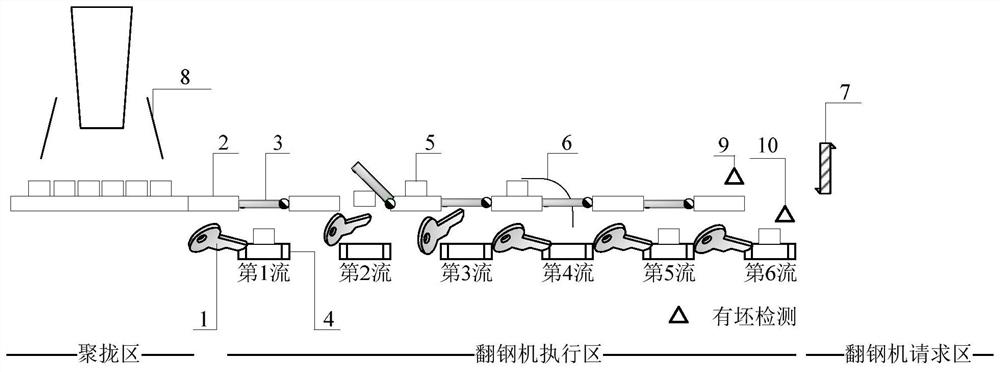

[0048] The moving of multi-strand slabs is realized through the turning machine; specifically, the function of the turning machine is to transport the continuous casting billets cut by the flame cutting machine to length equipment and turn them over from their respective billet roller tables To the unified billet moving track, and then transported to the cooling bed by the crane spreader for storage.

[0049] In the prior art, in order to realize the above-mentioned steel turning action, it is necessary that the running speed of the crane spreader should mee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com