Strand tension detection device and steel wire rope forming machine having same

A technology of tension detection and rope strands, which is applied in auxiliary devices for rope making, textiles and papermaking, textile cables, etc. It can solve the unstable quality control of finished steel wire ropes, the inability to ensure the consistency of tension between strands, and the inability to ensure rotation braking Torque consistency and other issues to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

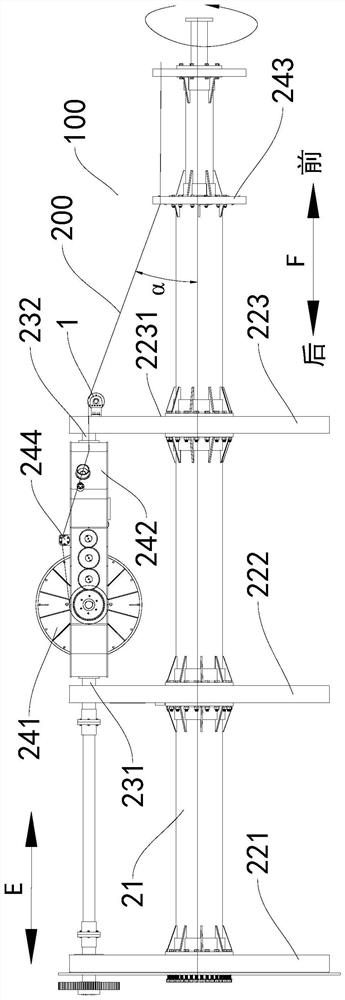

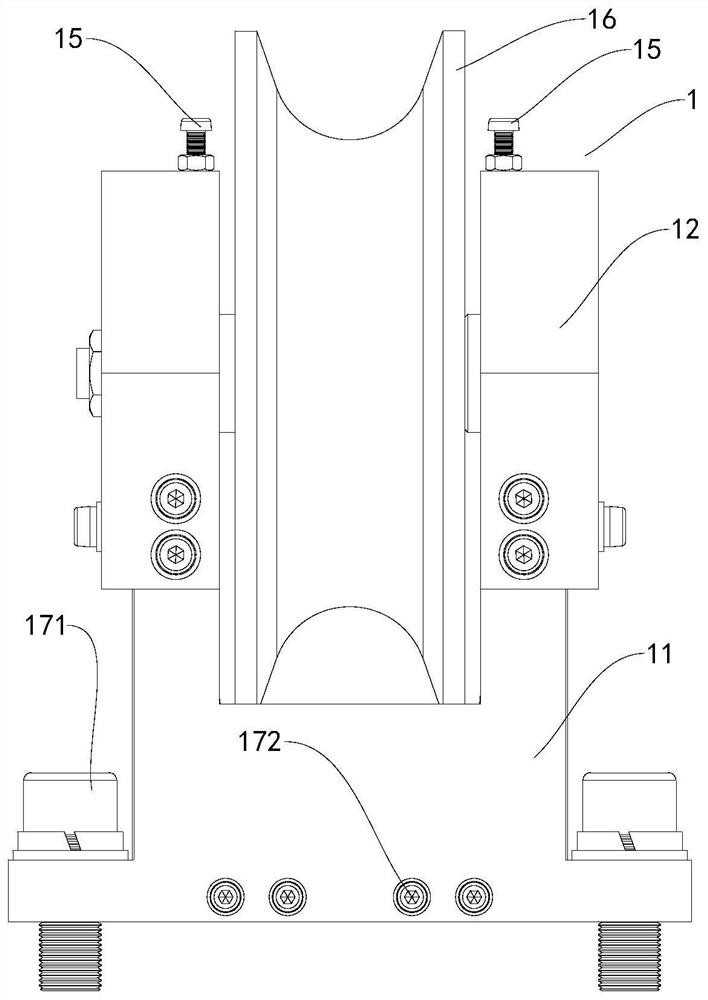

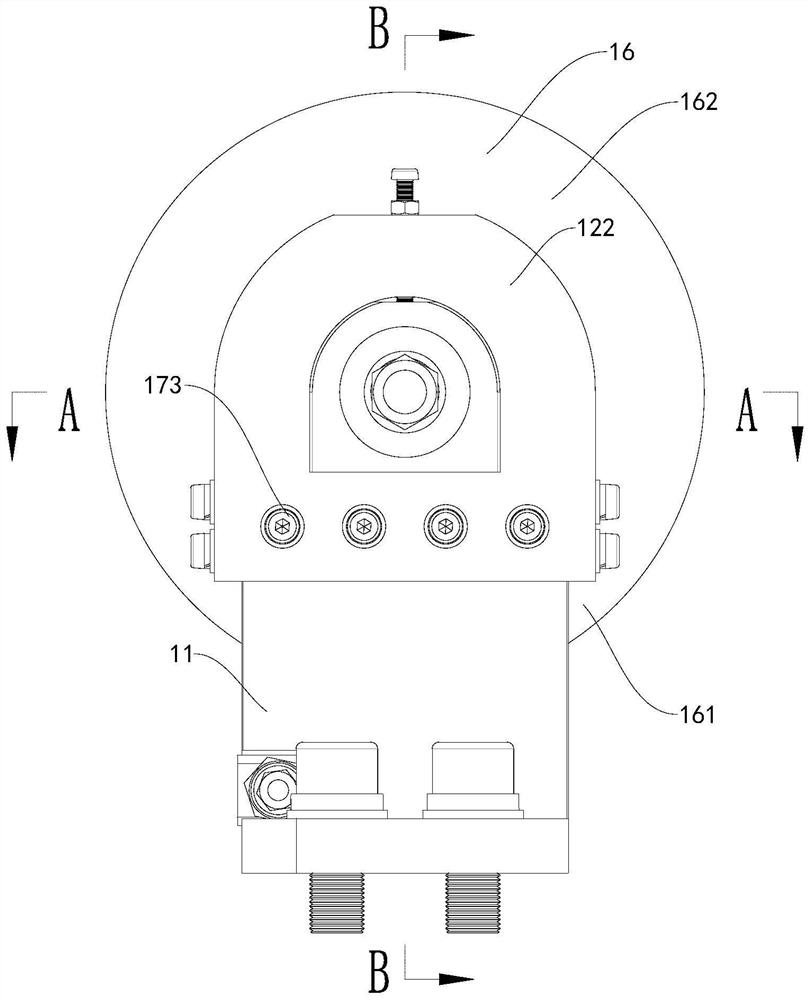

[0047] The following describes a wire rope forming machine 100 according to an embodiment of the present invention with reference to the accompanying drawings. Such as Figure 1-Figure 11As shown, the wire rope rope forming machine 100 according to the embodiment of the present invention includes a main shaft 21, a rear large plate 221, a middle large plate 222, a front large plate 223, a line dividing plate 243, a first shaft 231, a second shaft 232, a wire frame 242, a wire Wheel 241 and rope strand tension detection device 1.

[0048] The main shaft 21 is arranged horizontally. Each of the rear large plate 221 , the middle large plate 222 and the front larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com